Dental Material and Methods of Use

a technology of dental materials and compositions, applied in the field of dental material compositions, can solve the problems of reducing the adhesion to the walls of the canal, weakened root canals, and prone to fractur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

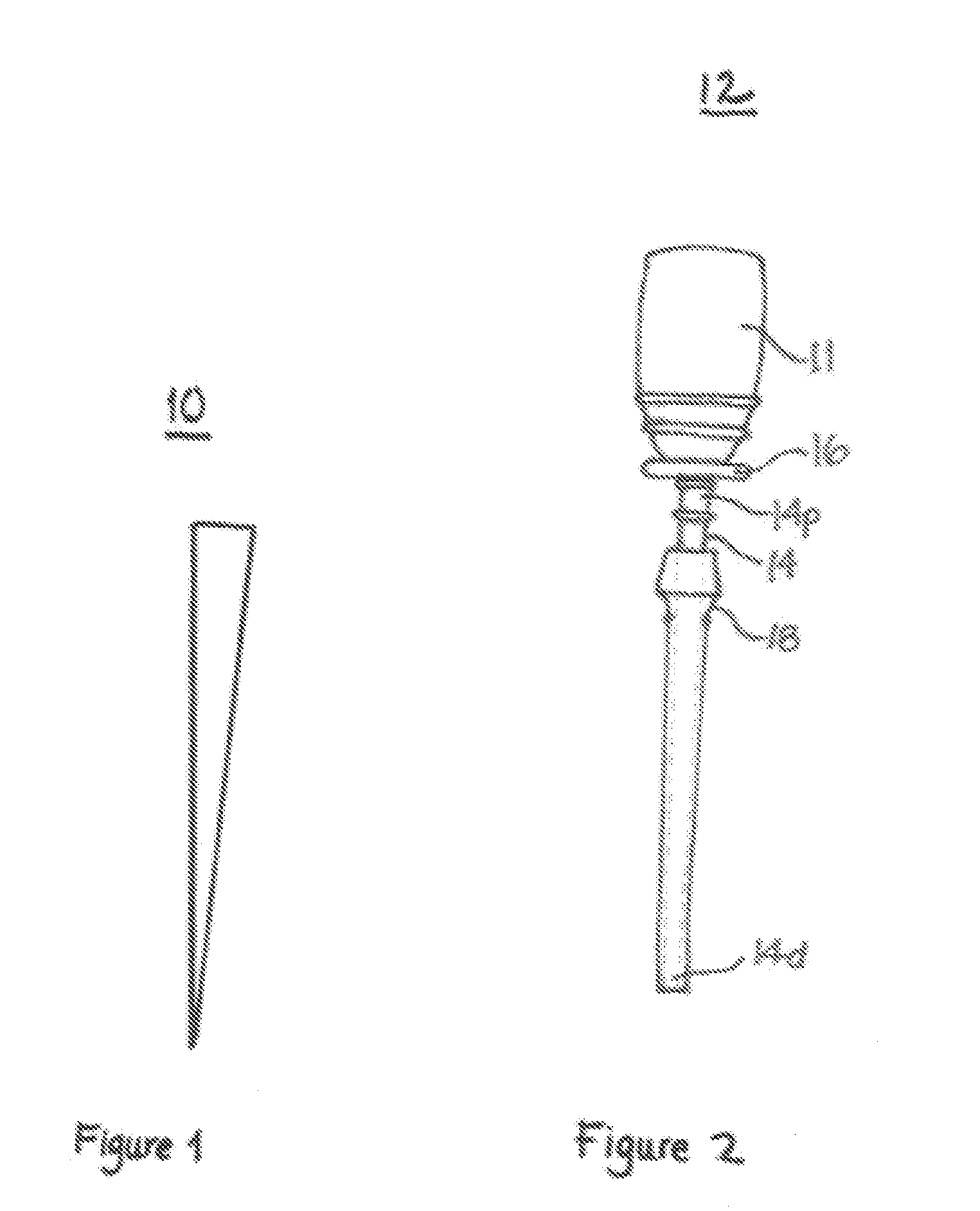

Image

Examples

example 1

[0044]Commercial polyisobutylene with an average molar mass of about 40,000 g / mol. and 85,000 g / mol. (Oppanol B 10 and Oppanol B 12 respectively, from BASF Chemical Company, Germany) were utilized. Table 1 below illustrates inventive dental filling material compositions.

TABLE 1Composition 1Composition 2Components(% by weight)(% by weight)Oppanol B 10 SFN40Oppanol B 12 SFN40Bismuthoxy Chloride6060

[0045]To blend the filler into the polybutylene polymer, the polymer was heated at the temperature of about 80° C. to melt it, then the filler was added and mixed until a homogenous putty compound was obtained. The compound was then cooled down to ambient temperature to form the inventive filling material. Alternatively, the polymer can be dissolved by a solvent and filler can be blended thereafter. Then, the solvent is pulled out under a negative pressure to form the dental filling compound.

example 2

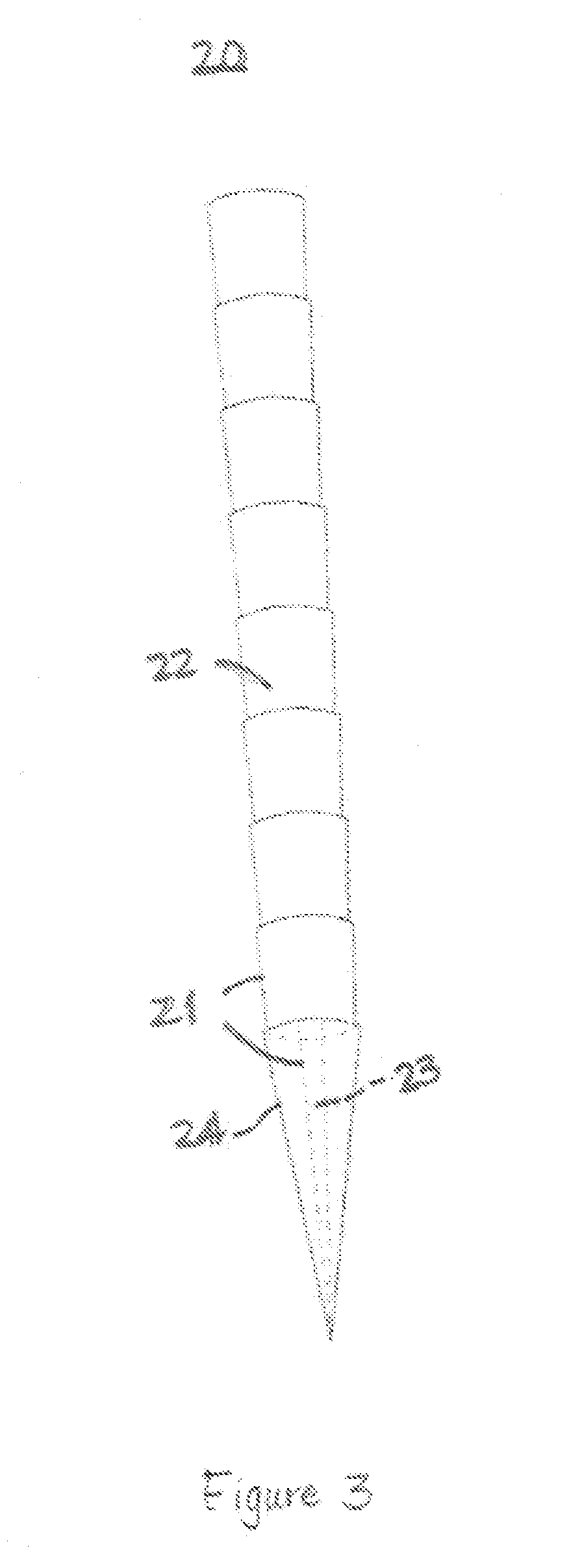

[0046]This illustrates the “cold flow” feature of the inventive dental filling materials. A testing method according to an abstract presented at the International Association for Dental Research Convention in Orlando, 2006, Abstract #1442 entitled “Influence of Rheology of Obturating Materials on Lateral Canal Flow” by Karmaker et al, which is hereby incorporated by reference, was used herein. Compositions 1 and 2 from Table 1 were hand molded onto a size 30 obturator carrier after the original gutta percha over-molding coating layer was peeled off to form an inventive “cold flow” filling cone. The new filling cone with the size 30 carrier was then inserted into a clear plastic endodontic trial block (available from Sybron Dental, CA) having a simulated root canal with a lateral thin canal in a perpendicular direction to the main canal at about mid point. The length of the lateral canal penetration by the outer layer coating material was then measured and compared. The deeper the pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molar mass | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com