Breakwater

a technology for breaking water and tetrapods, applied in the field of breaking water, can solve the problems of being properly unable to perform the function of breaking water, being unable to meet the requirements of installation, etc., and achieve the effect of reducing the burden of installation costs, reducing the burden of expenses, and reducing the cost of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040]Hereinbelow, breakwaters according to preferred embodiments of the present invention will be described with reference to the accompanying drawings.

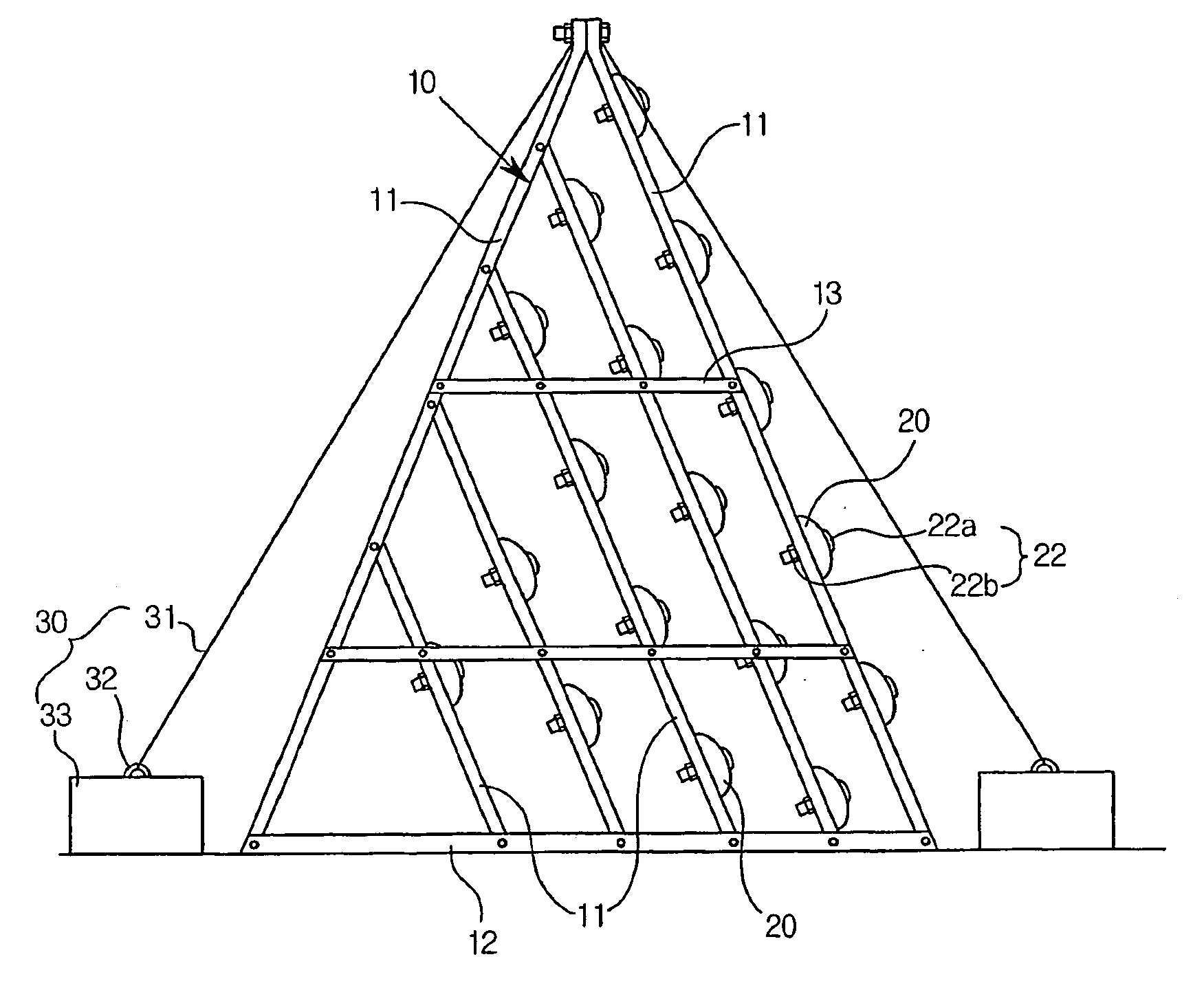

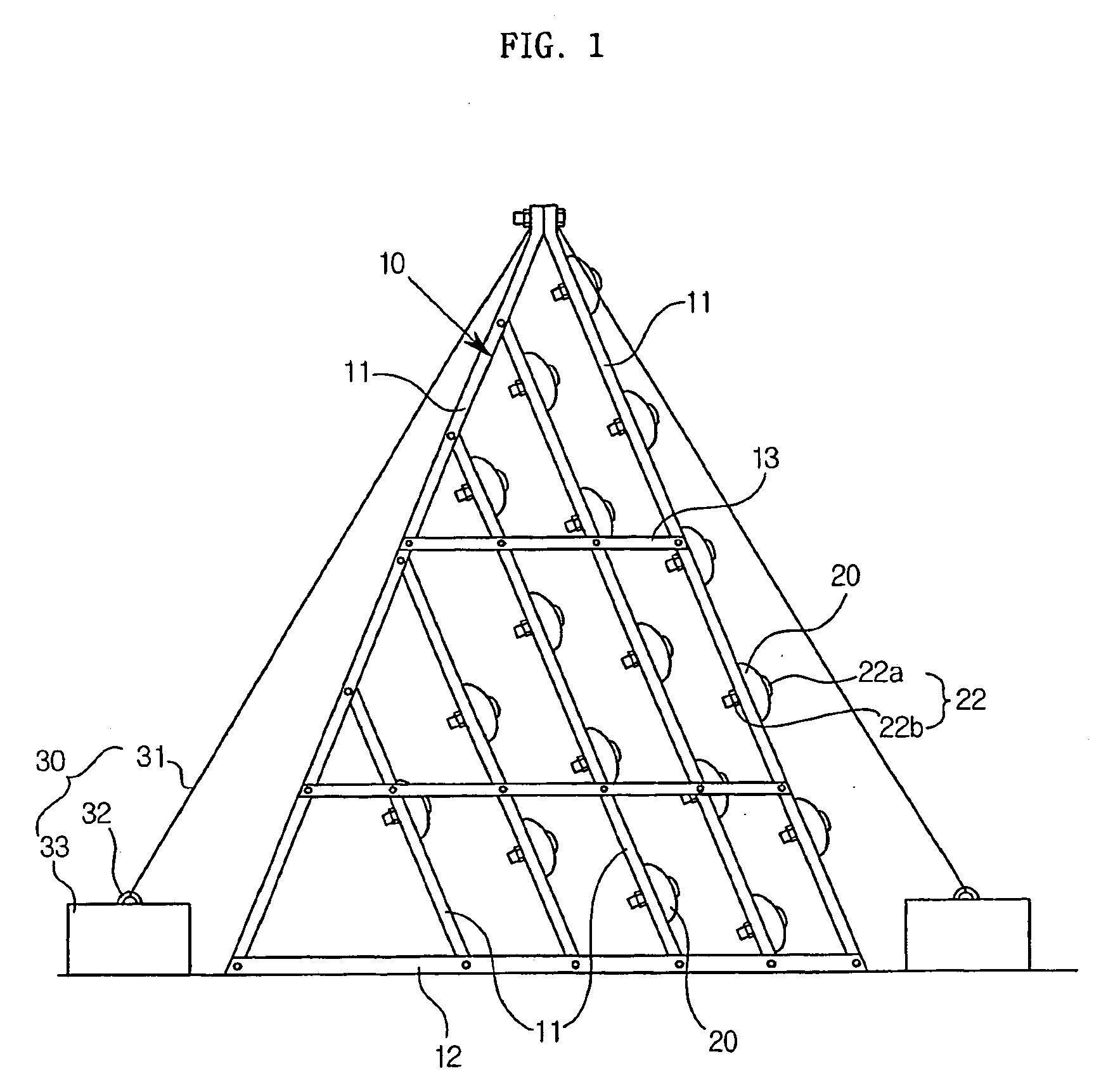

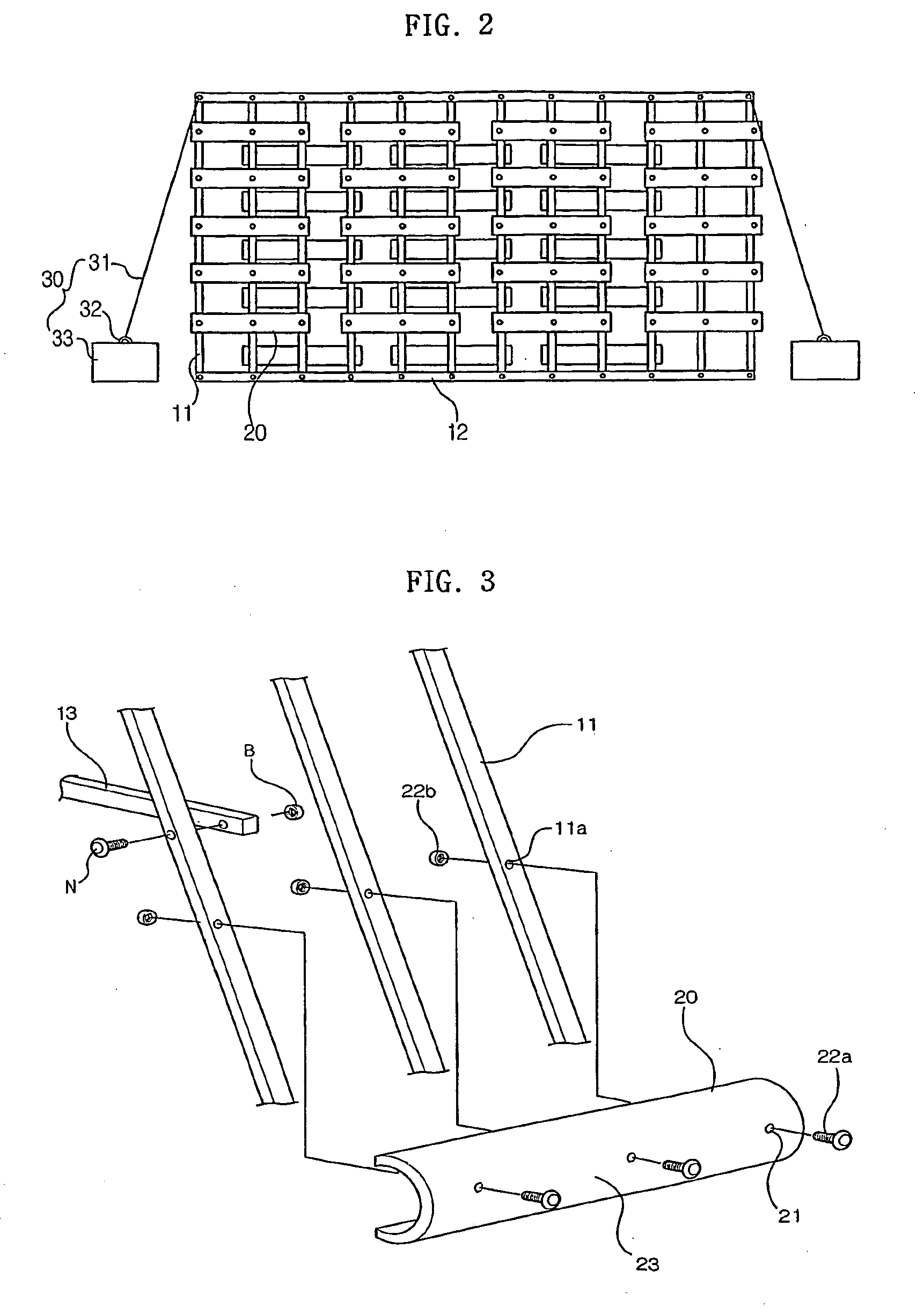

[0041]FIG. 1 is a side view showing an example of a breakwater according to the present invention. FIG. 2 is a front view showing an example of the breakwater according to the present invention. FIG. 3 is a partially omitted disassembled perspective view showing a combination state of the compositional essential parts of the present invention.

[0042]As shown in FIGS. 1 through 3, a breakwater according to the present invention is installed at a seashore, seawall, harbor, or dock, in order to block waves or billows which are generated from the sea by the flood tide by the tsunami or the large typhoon named hurricane, cyclone, or cicada, to thereby reduce damage as much as possible.

[0043]Referring to FIGS. 1 through 3, the breakwater according to the present invention includes: a frame body 10 having a plurality of supporting frames 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com