Hydrated Food

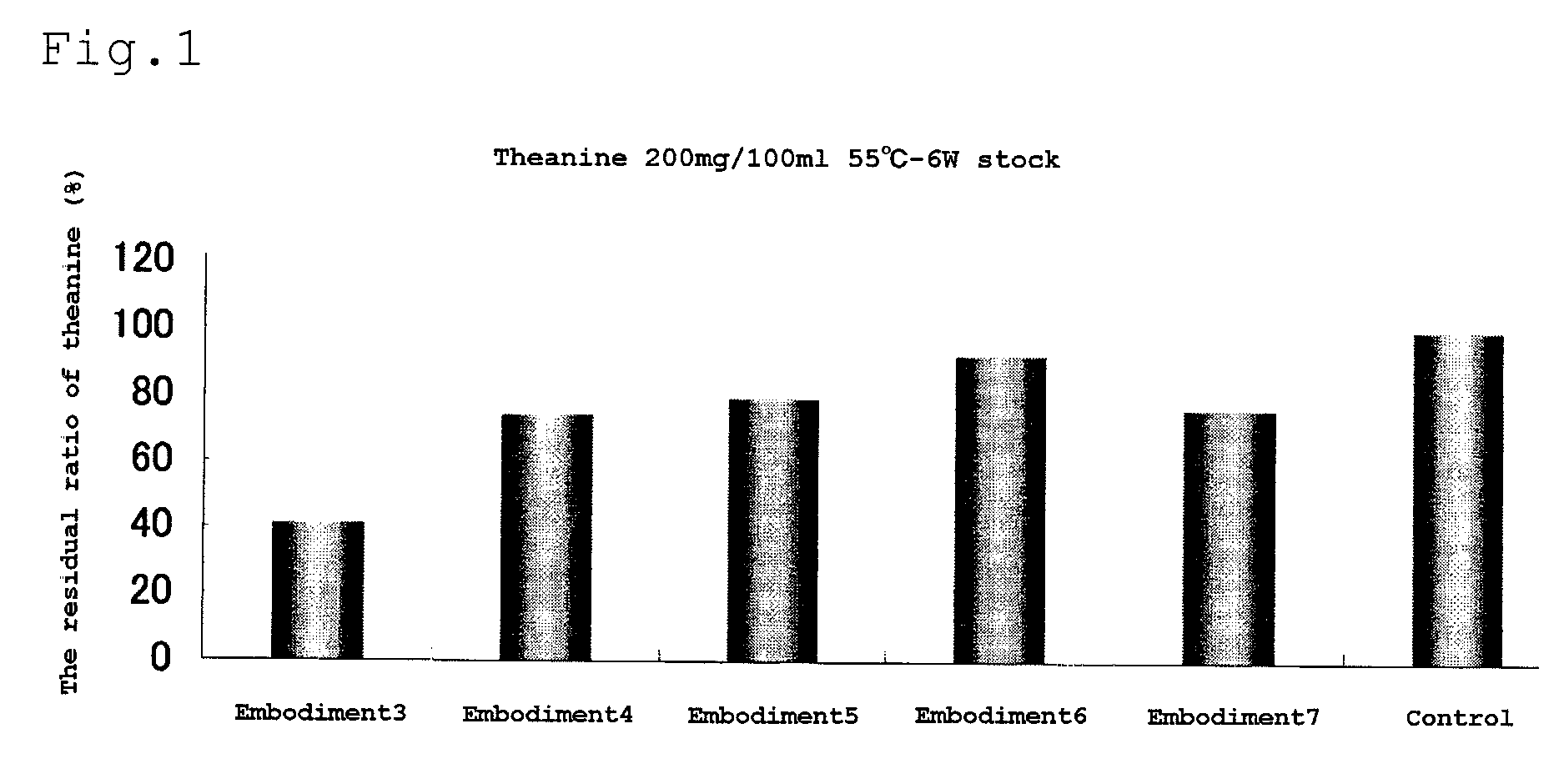

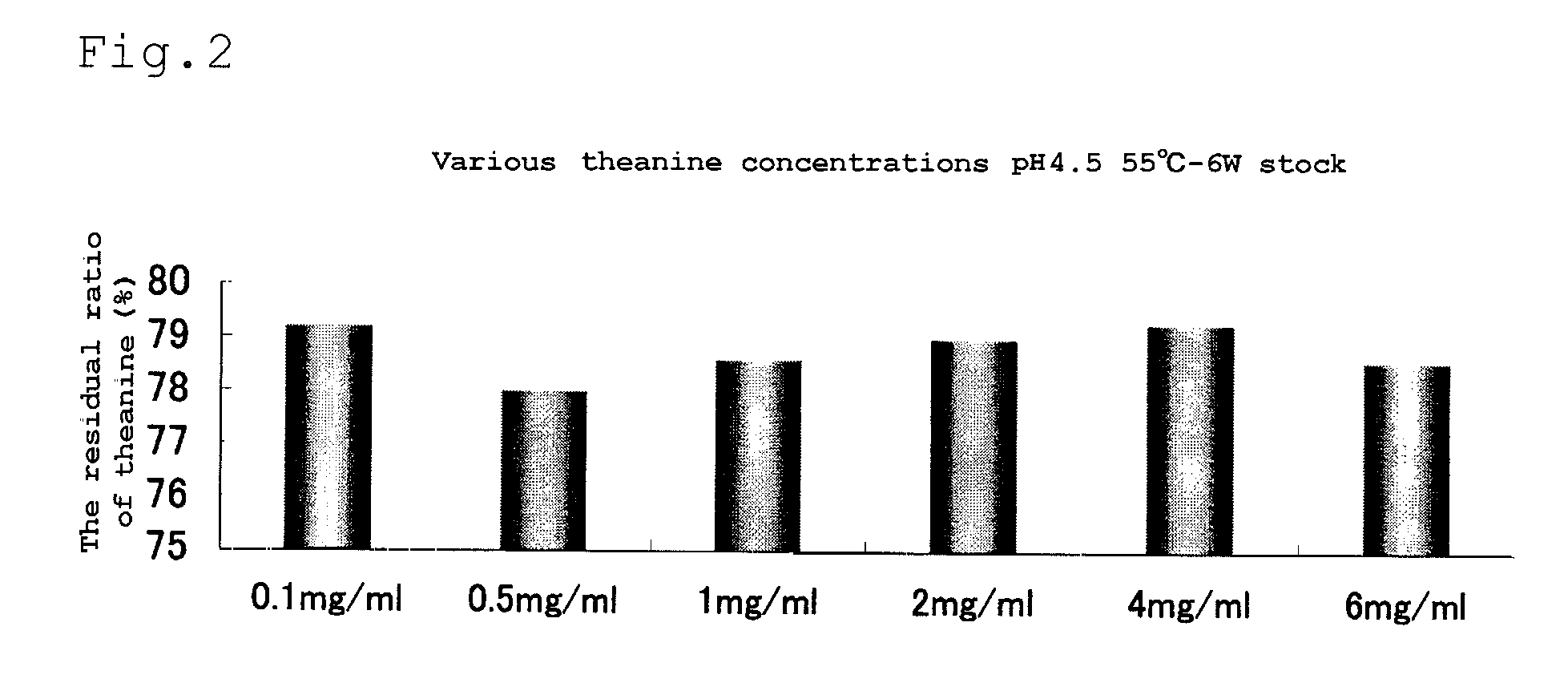

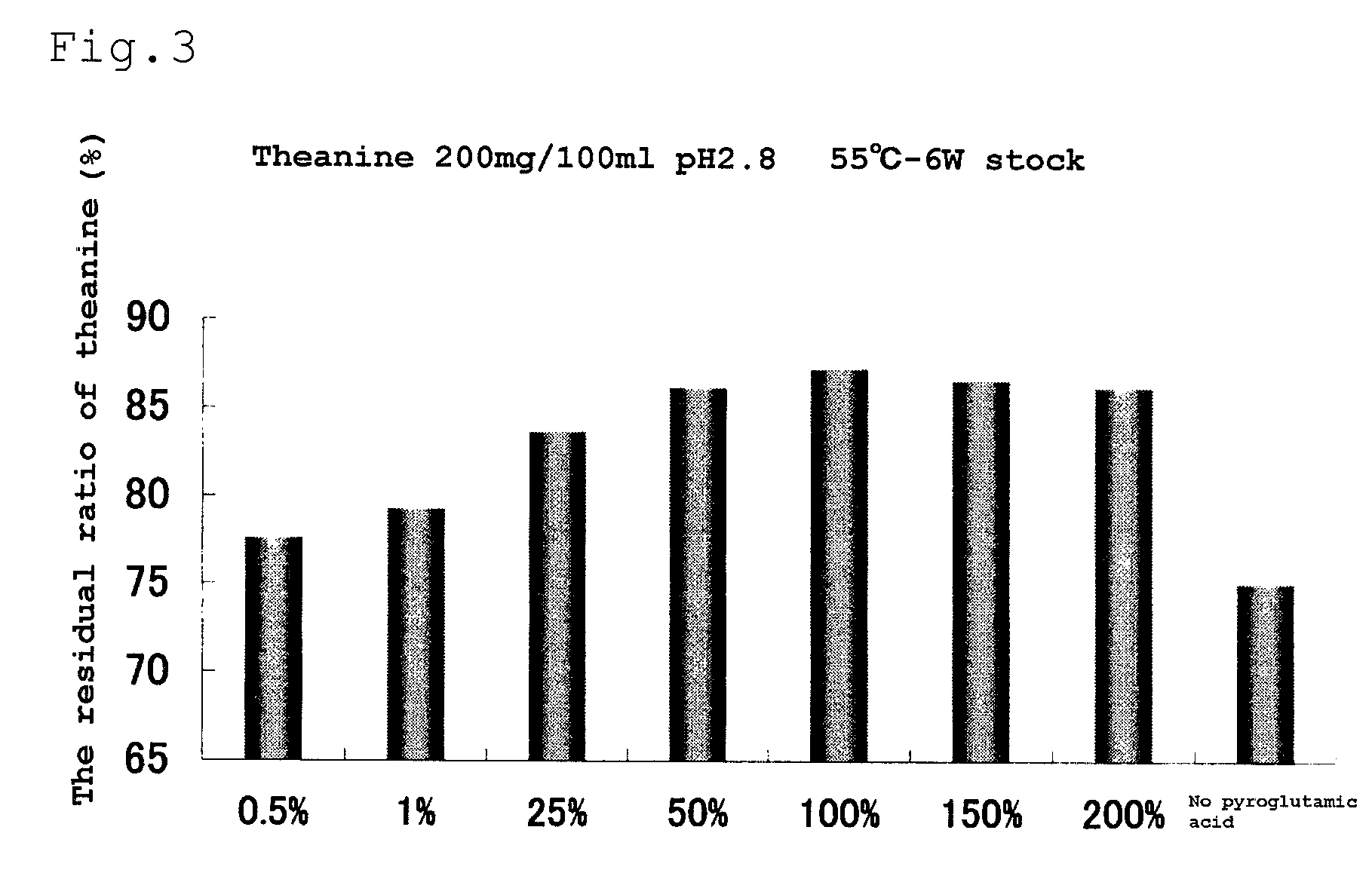

a technology of hydrated food and pyroglutamic acid, which is applied in the field of hydrated food, can solve the problems of reduced theanine content, decomposition of theanine, and few things are generally known about the effects of pyroglutamic acid, and achieve the effect of superior preservation and stability of theanine, and improving the taste threshold of food

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

Manufacture of Theanine by Enzyme Method

[0059]0.3 M glutamine and 1.5 M methylamine hydrochloride were reacted in the presence of 0.3 U glutaminase (commercially available) at 30° C. for 22 hours in a buffer solution of 0.05 M boric acid (pH 11), whereby 225 nm theanine was obtained. Reaction liquid was applied to Dowex 50×8 columnar chromatography and Dowex 1×2 columnar chromatography (both made by Muromachi Chemical Co., Ltd.) thereby to be processed by ethanol, whereby an object substance is isolated from the reaction liquid.

[0060]The isolated substance was applied to an amino acid analyzer (made by Hitachi Co.) and paper chromatography. Since the isolated substance behaved in the same way as a standard substance, it was recognized as L-theanine. When the isolated substance was processed by hydrolysis using hydrochloric acid or glutaminase, glutamine acid and ethylamine were produced in a ratio of 1:1. Thus, since the isolated substance was hydrolyzed by glutaminase, it was shown...

embodiment 2

Extraction of Theanine from Tea Leaves

[0061]10 kg tea leaf (Camellia sinensis) was extracted using heated water and thereafter, the obtained extract was passed through a cation exchange resin (type HCR W-2 made by Muromachi Chemical Industry Co., Ltd.) so as to be eluted by 1N NaOH. Eluted fraction was passed through activated charcoal (Taiko activated charcoal SG made by Futamura Chemical Industry Co., Ltd. The fraction eluted by 15% ethanol was concentrated using an RO film (type NTR 729 HF made by Nitto Denko Corporation). The concentrated eluted fraction was refined by columnar chromatography and then re-crystallized such that 24.8 g theanine was obtained.

[0062]L-theanine (product name: Suntheane made by Taiyo Kagaku Co., Ltd.) and valine (manufactured by Ajinomoto Co. Inc.) were used in the following experiments and production of each composition.

embodiment 3

Theanine Solution Preparation 1

[0063]10 mM citric acid solution and acetic acid were suitable mixed together and prepared so that pH of the mixture became 2.0. 200 mg L-theanine was added to 100 mL of the prepared solution to be dissolved and thereafter passed through a 0.45 um filter, whereby 2 mg / mL L-theanine solution with pH of 2.0 was prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com