Seismic support and reinforcement systems

a technology of seismic support and reinforcement system, applied in the direction of girders, machine supports, building repairs, etc., can solve the problems of not meeting current uniform building code (ubc) standards, many types of buildings may be heavily damaged, and the transfer mechanism is likely to be substandard, so as to eliminate or lessen dependence, the effect of simple and inexpensive, reliabl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

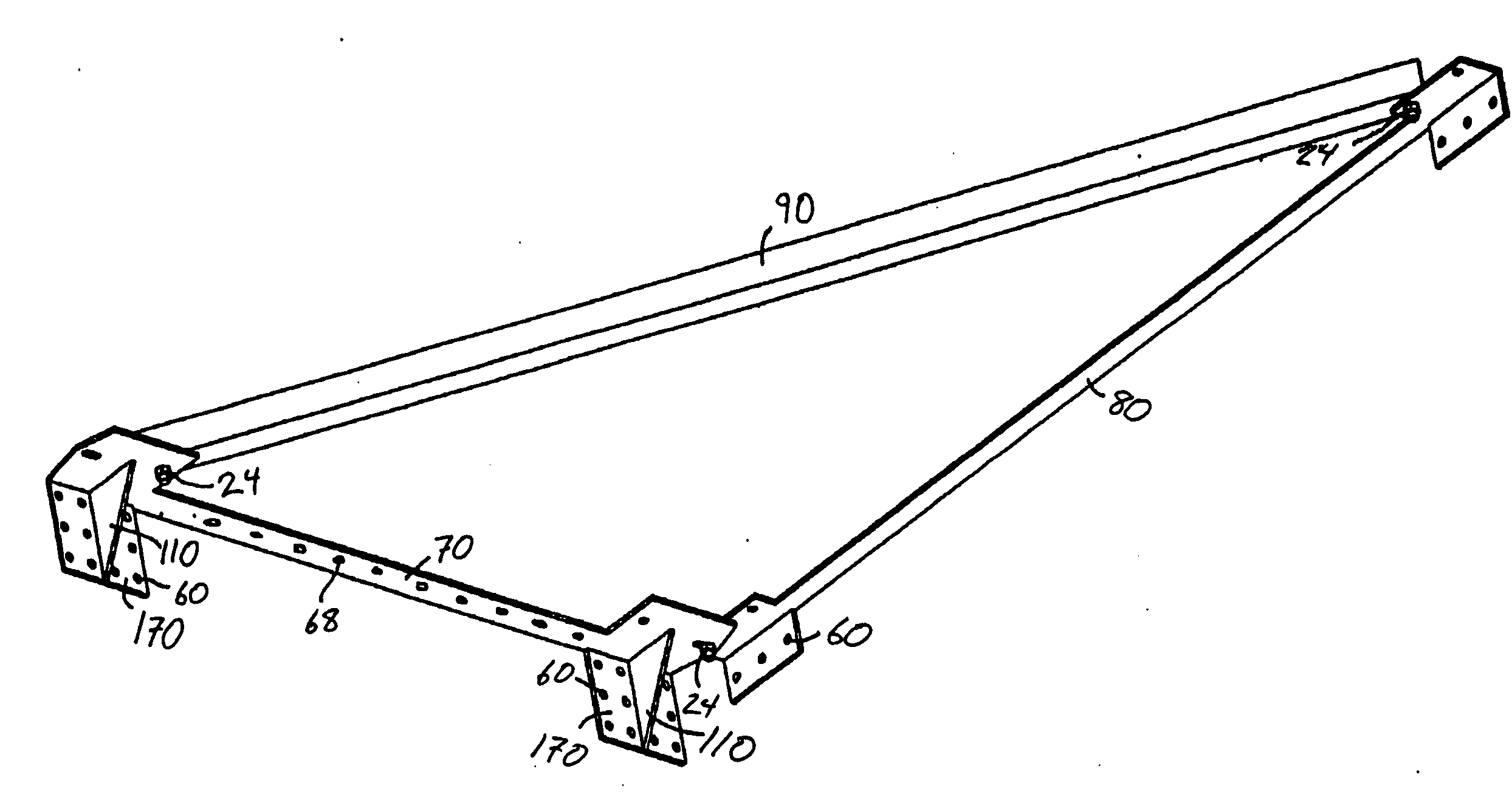

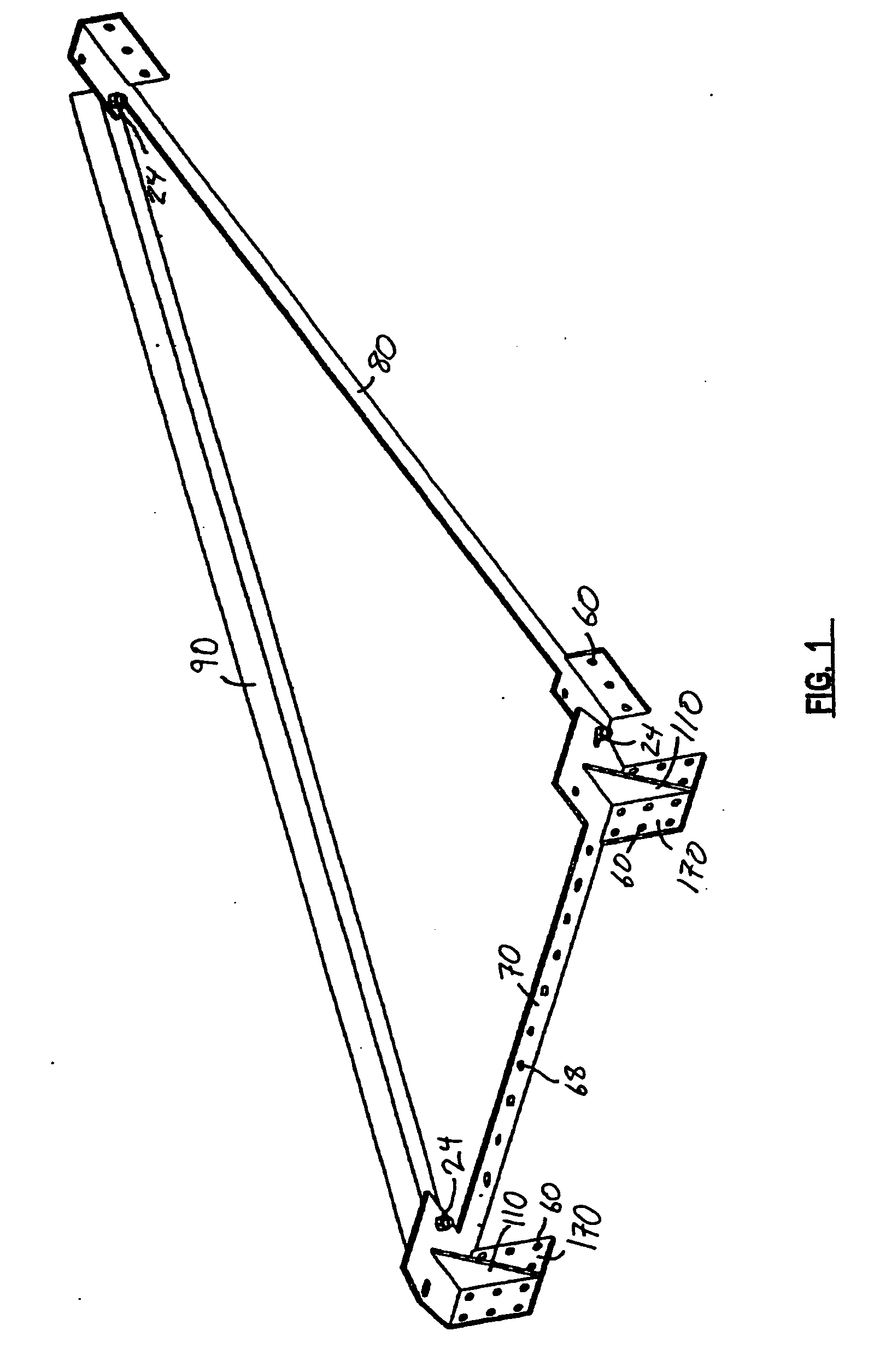

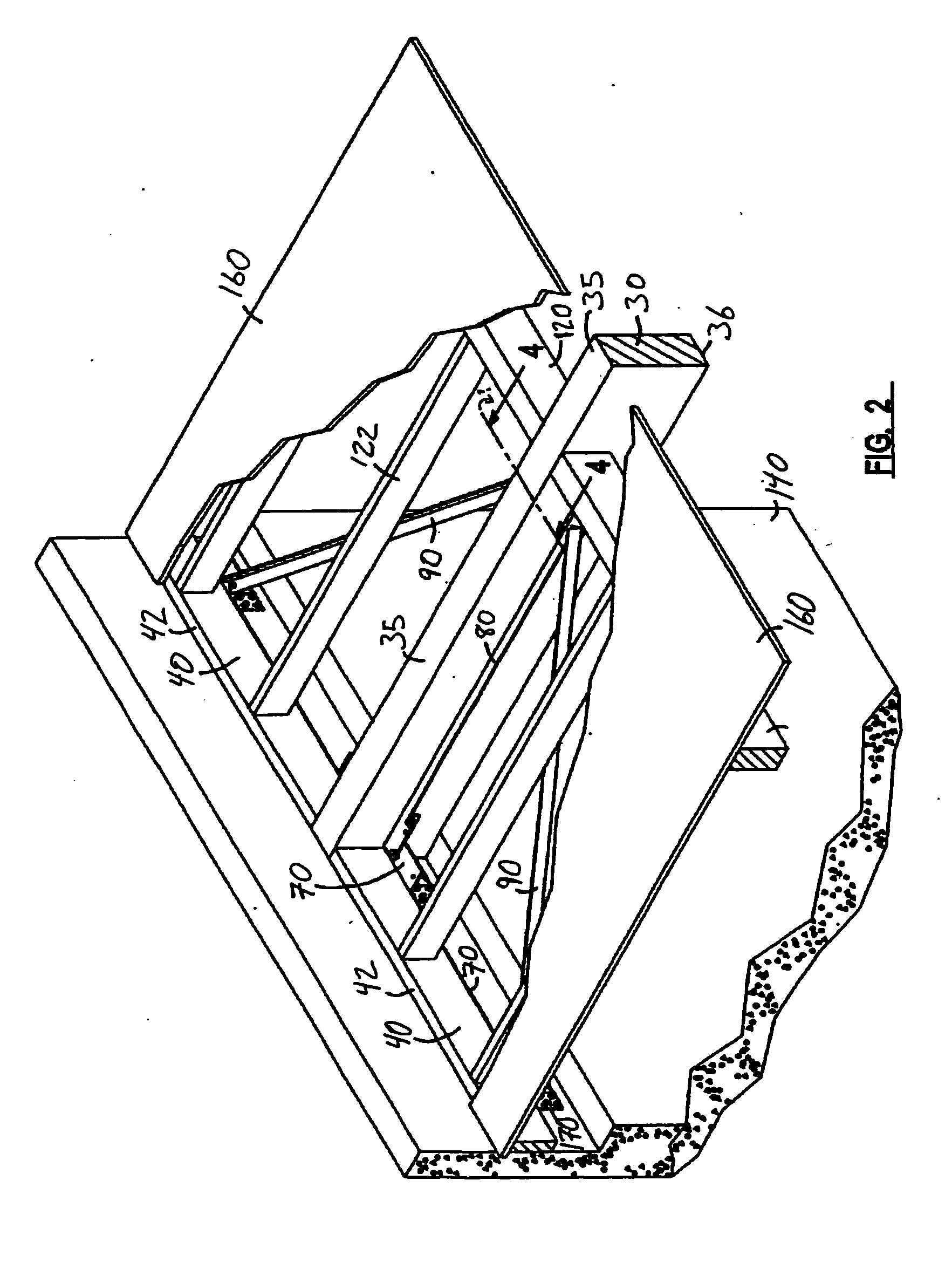

[0106]Referring to the drawings wherein like reference characters designate like or corresponding parts throughout the several views, and referring particularly to FIGS. 1-6, it is seen that a first embodiment illustrated in these drawings includes three elongated rigid (preferably metallic) bracket members 70, 80 and 90. These members may be used independently of each other, they may be used in combination with other support members, and / or they may be attached to each other in a triangular fashion as illustrated in FIG. 1. Some of the alternative and / or independent usages of members 70, 80 and 90 are described and illustrated in other embodiments herein.

[0107]In the exemplary triangular embodiments illustrated in FIGS. 1-6, and referring particularly to FIG. 3, it is seen that a first elongated member 70 is adapted for attachment along the underside 44 of a ledger 40 of a building roof, ceiling or floor support system. In some embodiments, bracket member 70 is not attached to ledg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com