Activation of metal hydrides

a technology of metal hydride and metal hydride particles, which is applied in the direction of combustible gas purification/modification, cell components, bulk chemical production, etc., can solve the problems of metal or metal hydride particle fracturing, and achieve the effect of preparing for vaporization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

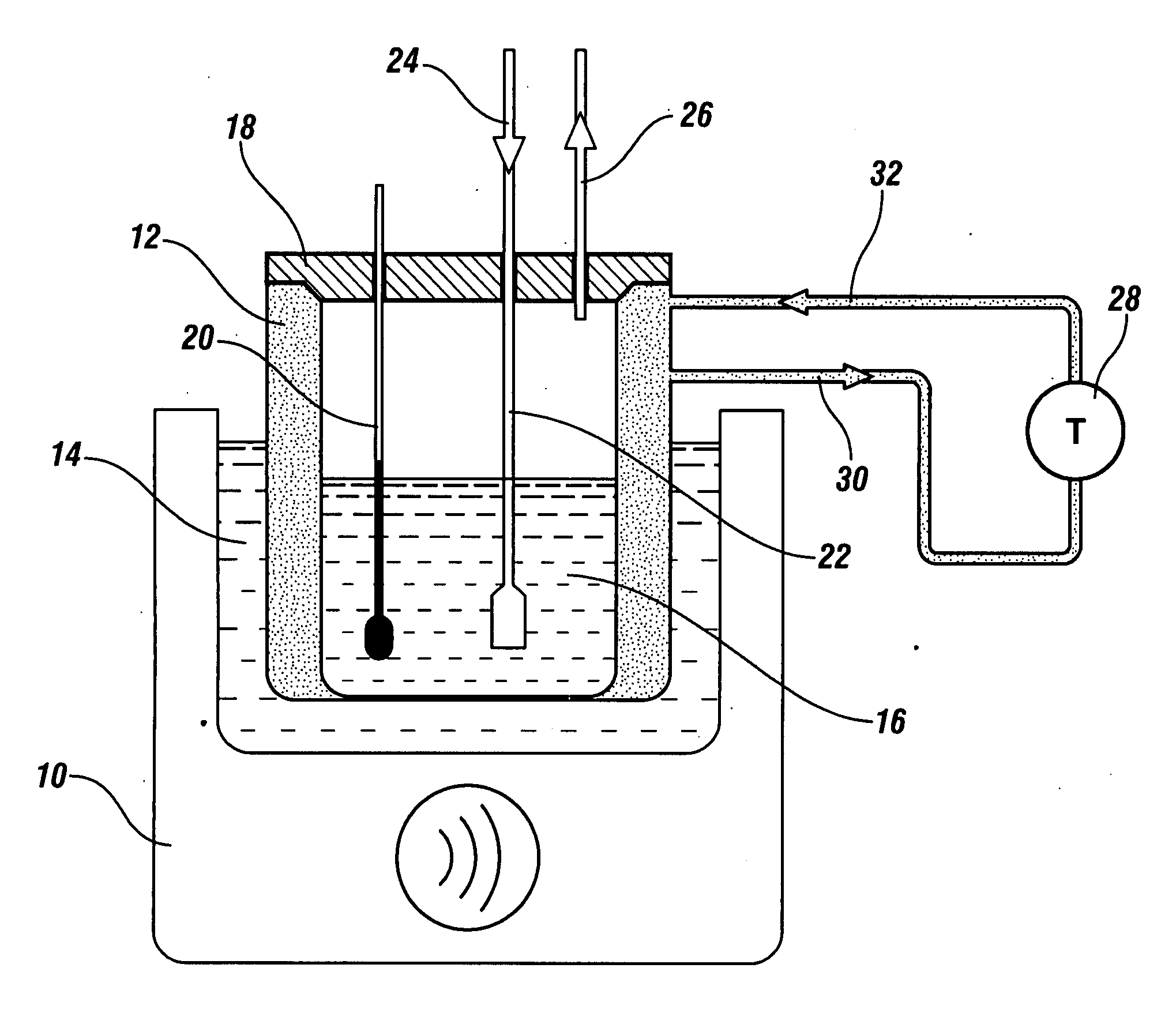

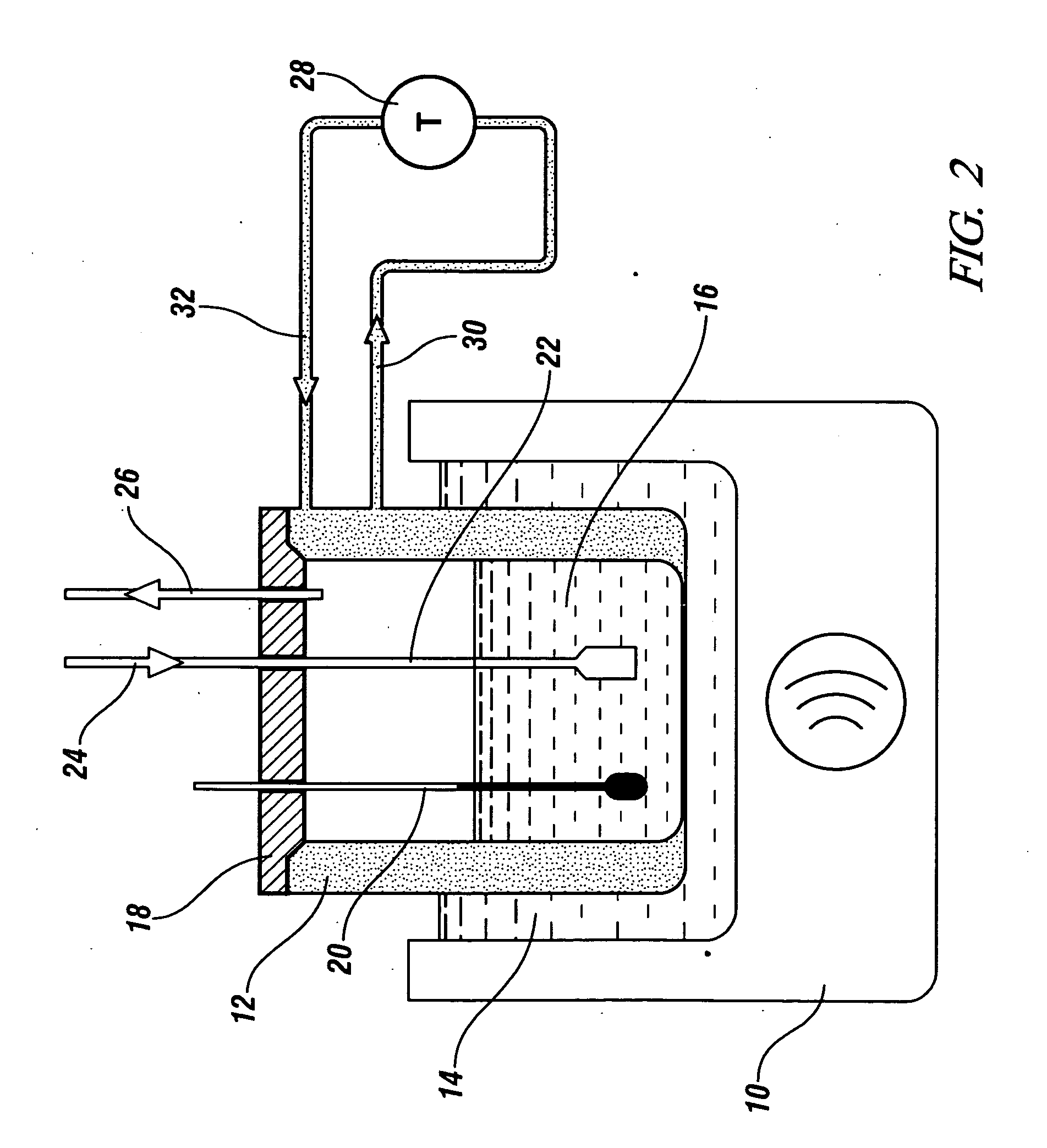

Embodiment Construction

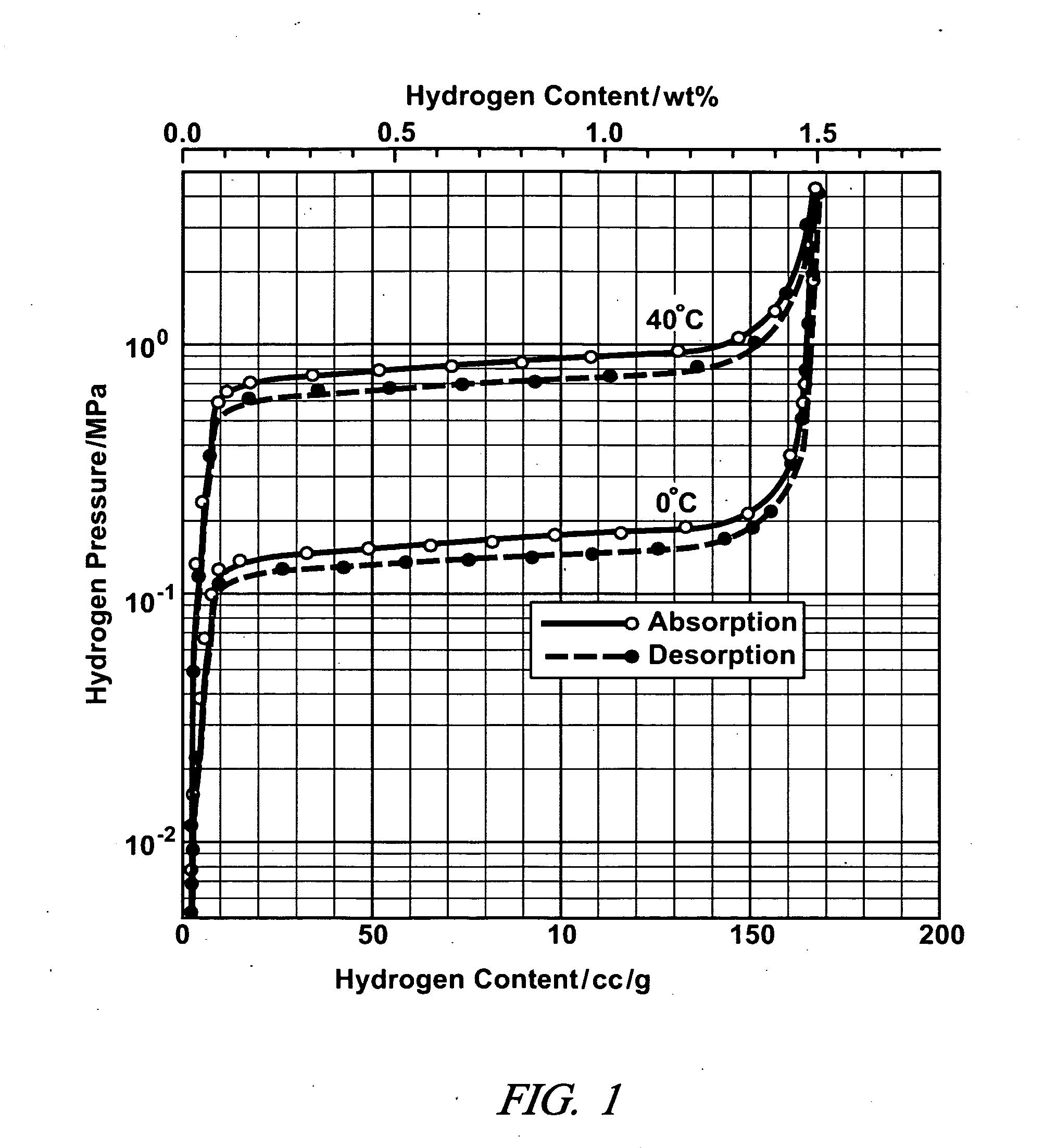

[0017]The most promising chemical reactions for on-board H2 storage are equilibrium reactions that alternately store and release H2 according to the phase, temperature and pressure of the system. One class of such chemical reactions is those involving metal hydrides. Metal hydrides undergo reversible chemical reactions which, under conditions of temperature and pressure that are sometimes suitable for on-board vehicles, either absorb or release hydrogen. The parent metallics of metal hydrides typically take any of the following forms: A, AB5, AB2, AB, A2B where A and B are typically a mix of transition metals, or a mix of transition with either rare earth or alkaline earth metals. Table I shows examples of metal hydrides and their hydrogen storage properties.

TABLE IExamples of metal hydrides with known hydrogen storagepropertiesTypeMetalHydrideStructureMass % H2Peq, TAPdPdH0.6Fm3m0.560.02 bar,298 KAB5LaNi5LaNi5H7P6 / mmm1.372 bar,298 KAB2ZrV2ZrV2H5.5Fd3m3.0110−8 bar,303 KABFeTiFeTiH2P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com