Refrigeration System

a technology of refrigerating system and air conditioner, which is applied in the direction of defrosting, domestic cooling apparatus, application, etc., can solve the problems of air adhesion and moisture, and achieve the effect of effective defrosting, and reducing the time taken to defros

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

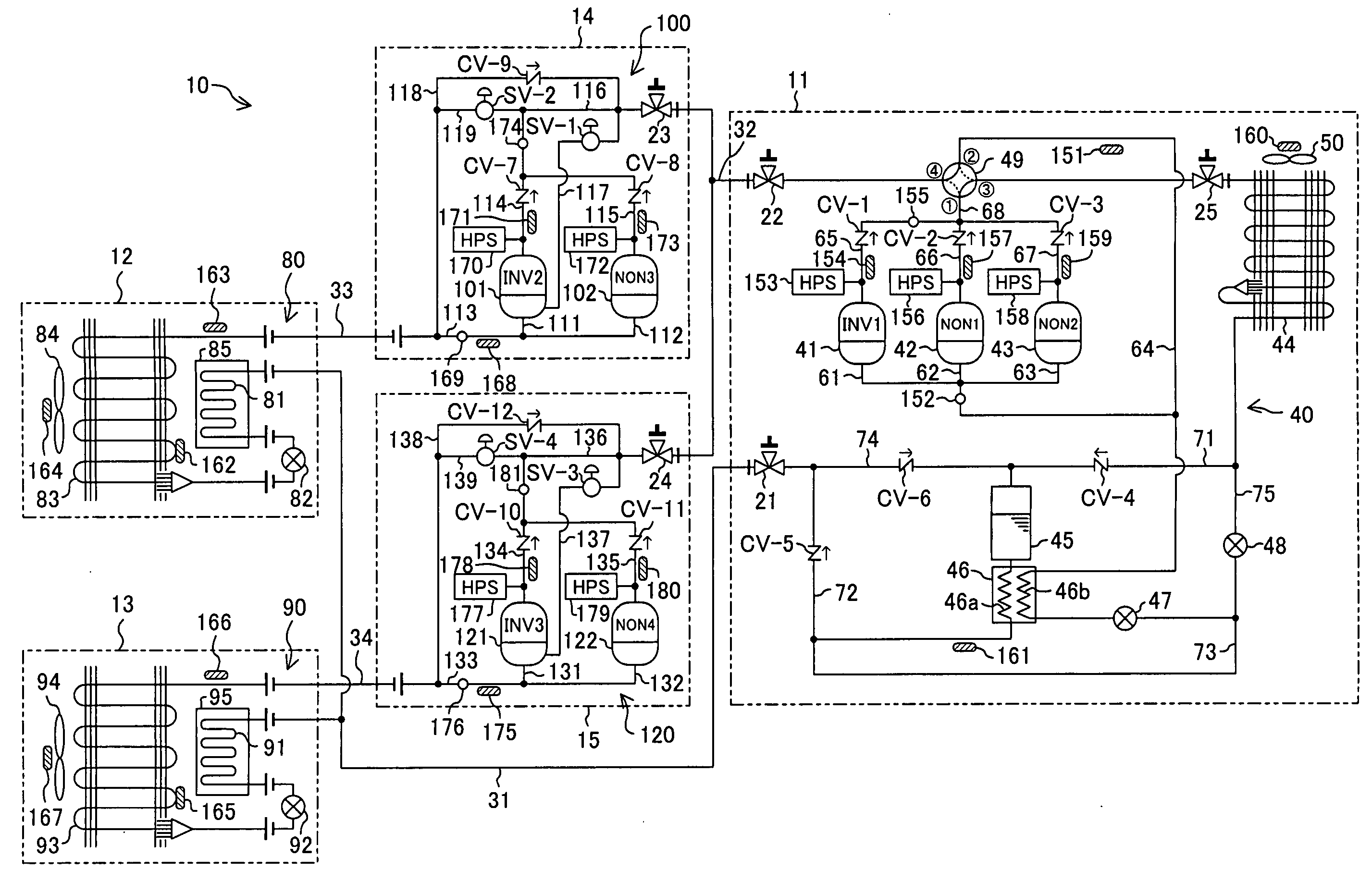

embodiment 1

Effects of Embodiment 1

[0142]According to Embodiment 1, during the defrosting operation, frost adhering to the surfaces of the cooling heat exchangers (83, 93) are heated from the insides of the cooling heat exchangers (83, 93) by feeding the refrigerant discharged by the high stage compressors (41, 42, 43) into the utilization side heat exchangers (83, 93). Therefore, the cooling heat exchangers (83, 93) can be effectively defrosted, which reduces the time taken to defrost them.

[0143]Furthermore, according to Embodiment 1, since during the defrosting operation the outdoor heat exchanger (44) serves as an evaporator, heat given from air to refrigerant is used to defrost the utilization side heat exchangers (83, 93). In other words, according to Embodiment 1, heat given to refrigerant by the high stage compressors (41, 42, 43) and heat given to refrigerant by the outdoor heat exchanger (44) are both used to defrost the cooling heat exchangers (83, 93). This reduces the time required ...

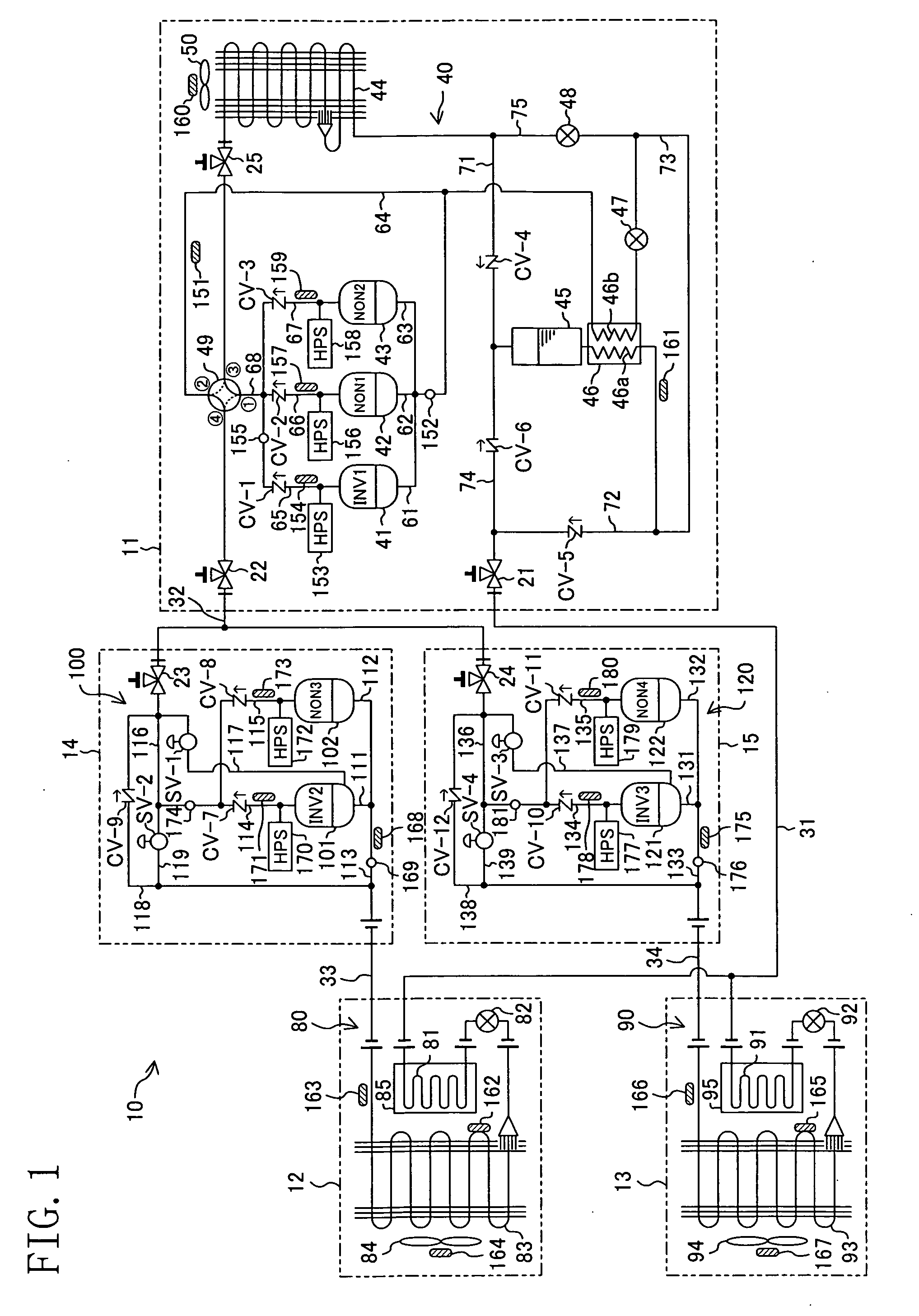

embodiment 2

Effects of Embodiment 2

[0163]According to Embodiment 2, like Embodiment 1, during the defrosting operation, frost adhering to the surfaces of the cooling heat exchangers (83, 93) are heated from the insides of the cooling heat exchangers (83, 93) by feeding the refrigerant discharged by the high stage compressors (41, 42, 43) into the cooling heat exchangers (83, 93). Therefore, the cooling heat exchangers (83, 93) can be effectively defrosted, which reduces the time taken to defrost them.

[0164]Furthermore, in Embodiment 2, the refrigeration system (10) can selectively perform the first defrosting operation and the second defrosting operation. According to Embodiment 2, when during the first defrosting operation the refrigeration system (10) is lacking in the capacity to defrost the cooling heat exchangers (83, 93), the low stage compressors (101, 102, 121, 122) are also driven. Therefore, according to Embodiment 2, the amount of heat given to refrigerant can be increased by the sec...

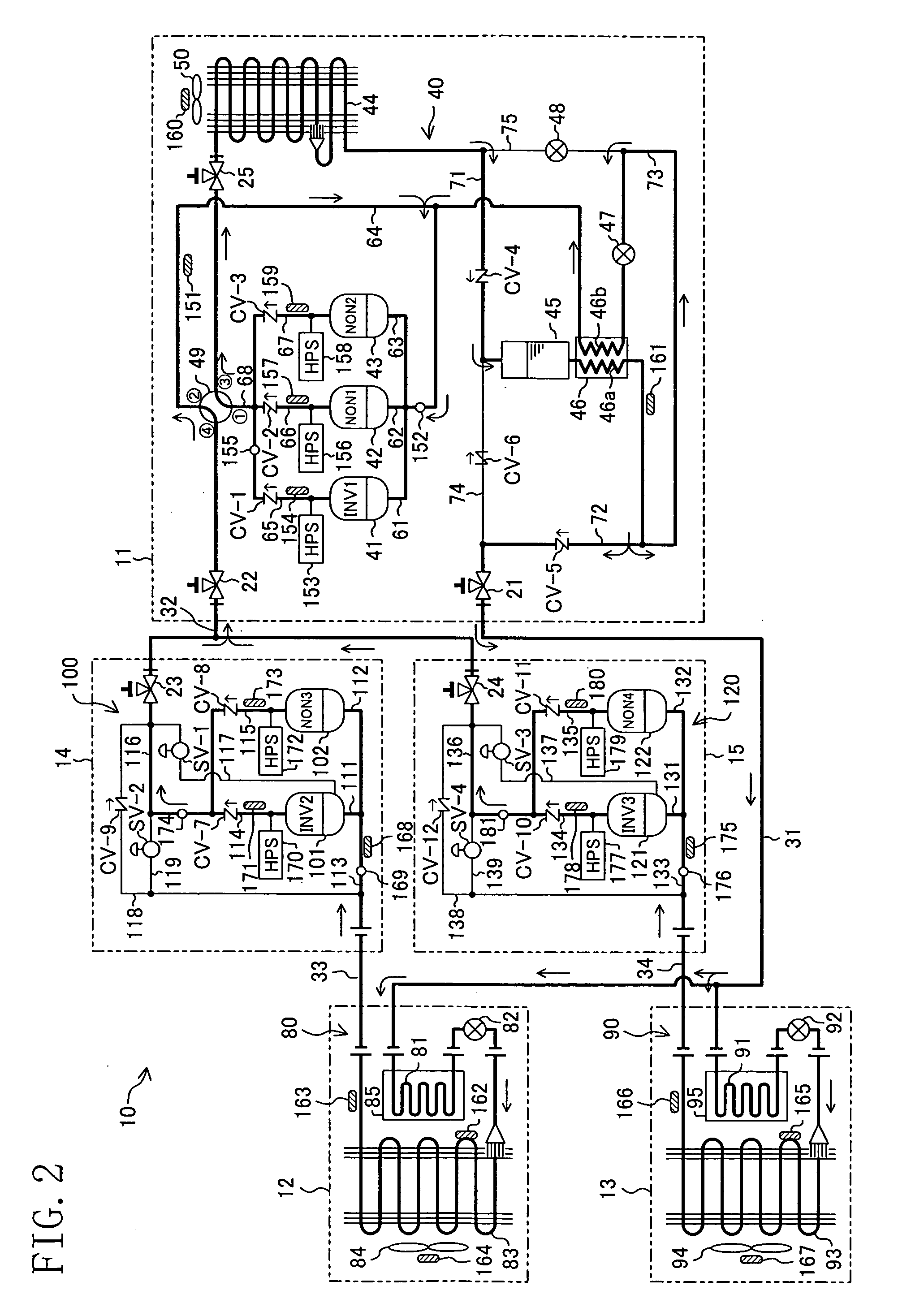

embodiment 3

Modifications of Embodiment 3

[0214]The oil separators (143, 144) and the oil return pipes (141, 142) described in Embodiment 3 may be applied to the refrigeration systems (10) of Embodiments 1 and 2 so that the refrigeration systems (10) can perform a similar cooling operation, a similar defrosting operation and a similar refrigerant recovery action to those in Embodiment 3. Furthermore, for example, in the booster circuits (100, 120) in Embodiment 3 shown in FIG. 9, the bypass pipes (119, 139) may be connected at their one ends to the discharge connection pipes (116b, 136b), respectively, and connected at the other ends to the low stage suction pipes (113, 133), respectively. According to this configuration, during the defrosting operation, the cooling heat exchangers (83, 93) can be defrosted, without sending high-pressure refrigerant into the oil separators (143, 144), by directly introducing it into the bypass pipes (119, 139).

[0215]Furthermore, for example, as shown in FIG. 11,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com