Devices for firing a projectile

a projectile and device technology, applied in the direction of firing/trigger mechanism, ammunition, weapons, etc., can solve the problems of device requiring a relatively large charge and long barrel, device can take a relatively long time to be primed for firing, and additional barrel breech does increase the size and weight of the devi

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

[0058]Turning to FIG. 5 to 7, the cartridge in accordance with the invention has a three part housing formed from two cupped aluminium end pieces 100 and 102 attached one to either side of a central, cylindrical, stainless steel connector 104.

[0059]The cupped piece 102 defines a chamber 106 which contains two propellant charge portions 108 and 110 which correspond to the first propellant charge 34 of the first embodiment. The charge portion 110 is of a relatively slow burning explosive propellant material, whilst the charge portion 108 is of a faster burning explosive material. The two charge portions are separated by a paper disc 112. Similarly, the cupped end piece 100 defines a chamber 114 in which are contained a charge portion 116 of slow burning explosive propellant separated by a paper disc 118 from a charge portion 120 of fast burning explosive propellant. The charge portions 120 and 116 correspond to the second propellant charge 36 of the first embodiment. As can be seen fr...

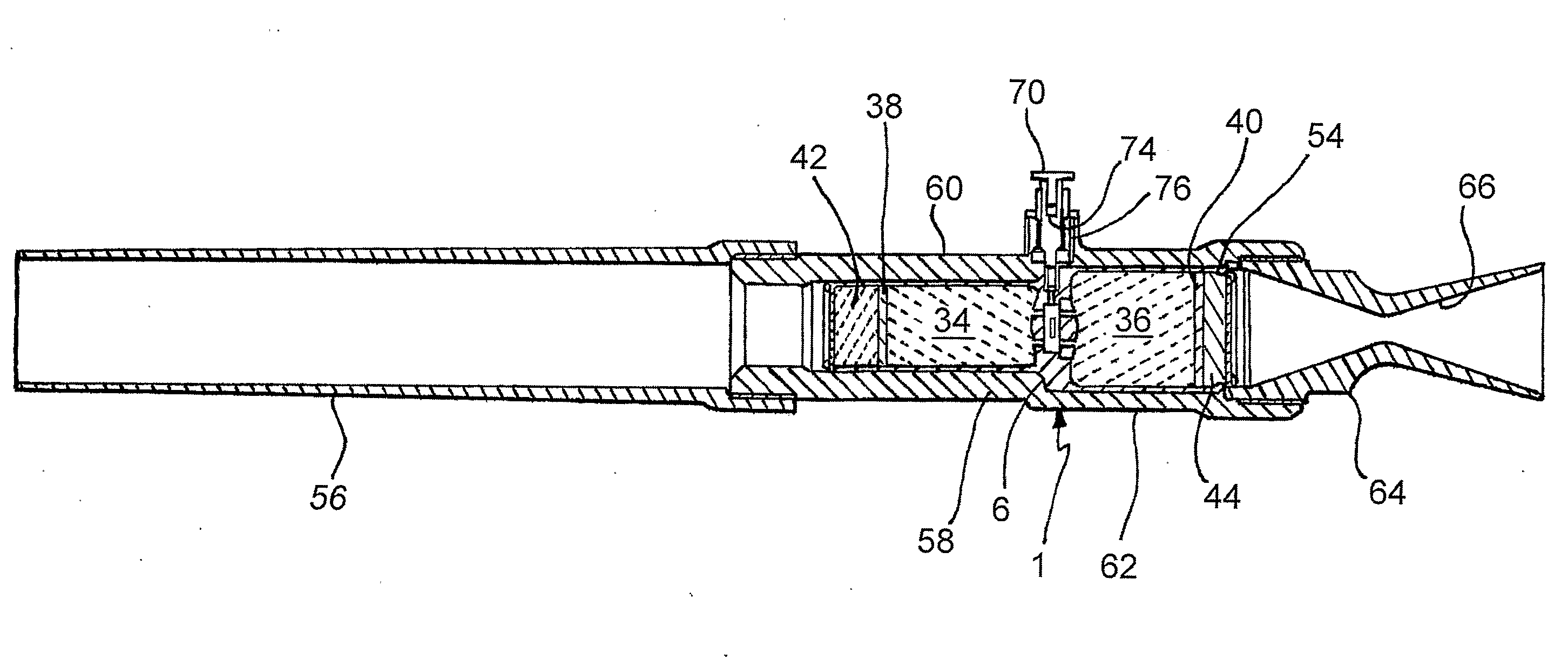

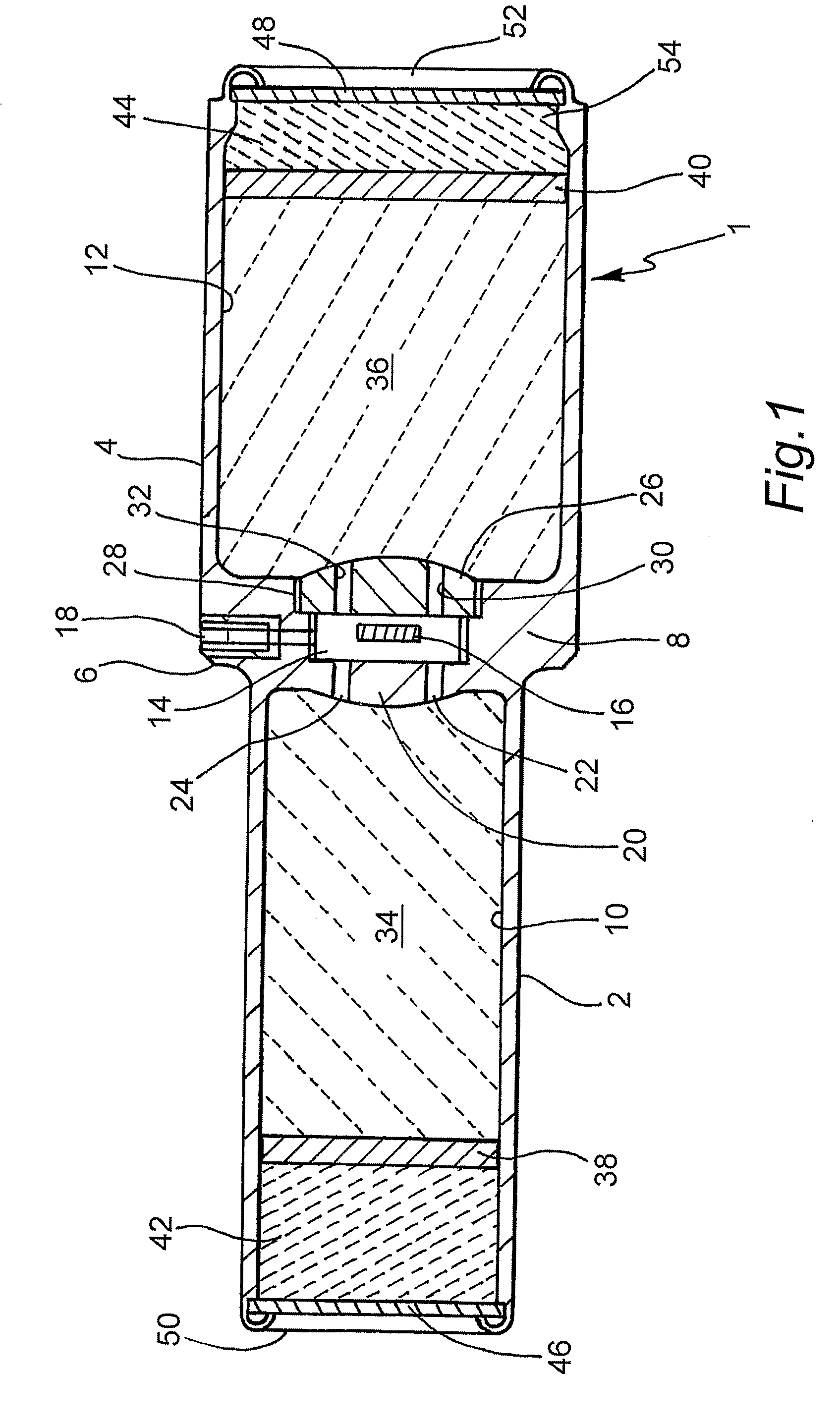

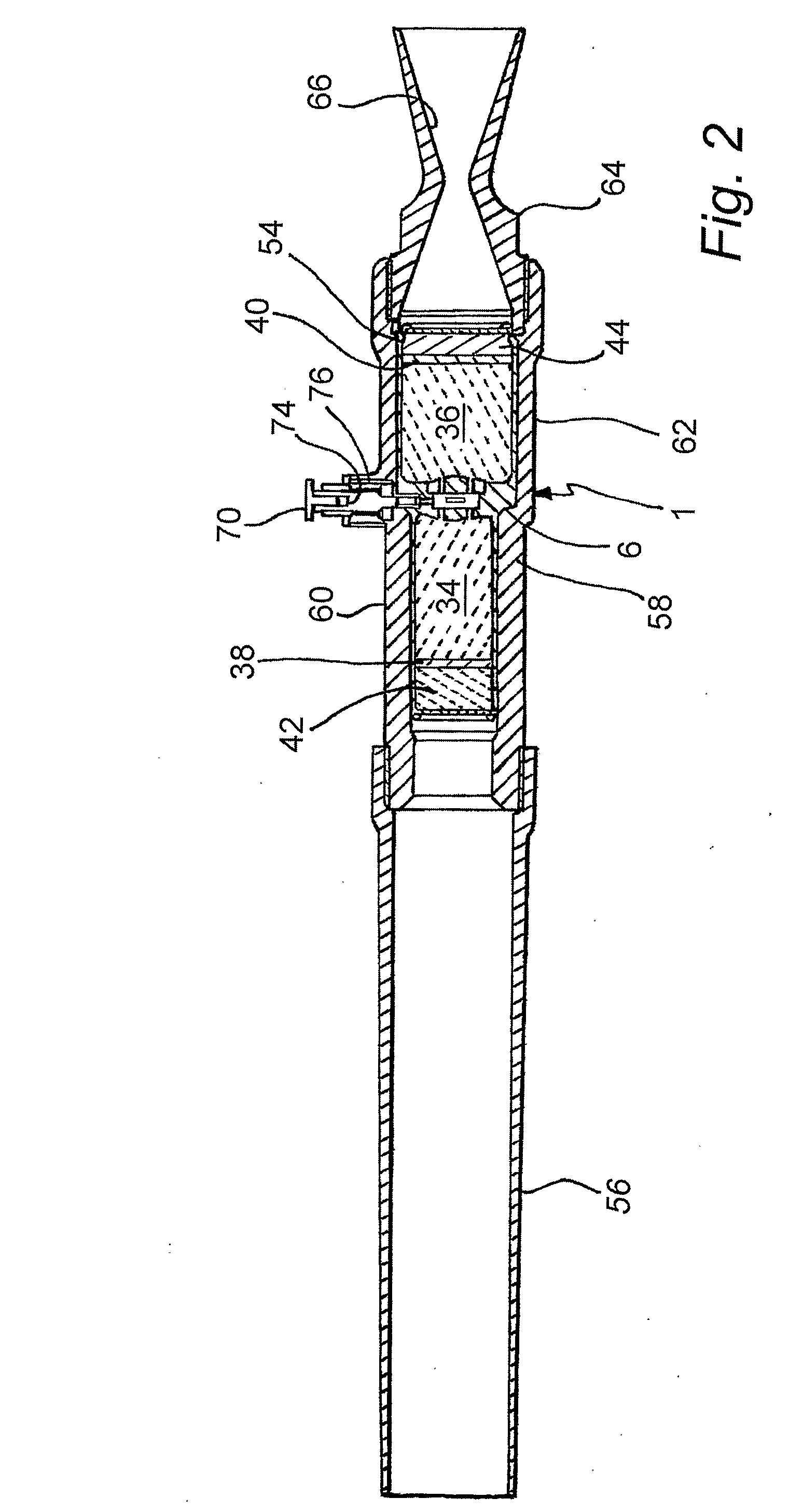

first embodiment

[0063]The collar 132 also has an internal screw thread 134 via which an externally screw threaded stainless steel plug 136 is attached to the connector 104 to define a bulkhead for the chamber 106. An eccentric axial bore 138 connects the chamber 106 to an ignition chamber 140, which contains an electrical fuse head 142 (similar to the fuse head 16 of the first embodiment). As with the fuse head 16, one side of the fuse head wire is connected to a positive electrical contact 144, the other to earth, and an axial brass ferrule 146 lines the ignition chamber 140.

[0064]The side of the chamber 140 opposite to the plug 136 is provided with a short passage 148 which is concentric with the connector 104, and which leads a dished seat portion 150. The seat portion leads to a small, generally cylindrical gallery 152 which accommodates a valve member 154 comprising a steel ball. The gallery 150 is formed in a stainless steel, axial plug 156 which is provided with a central axial bore 158 situ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com