Turbo fan for blowing and refrigerator having the same

a technology for refrigerators and fans, applied in the direction of wind motors with parallel air flow, wind motors with perpendicular air flow, liquid fuel engine components, etc., to achieve the effect of minimizing power consumption and noise, and improving blowing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

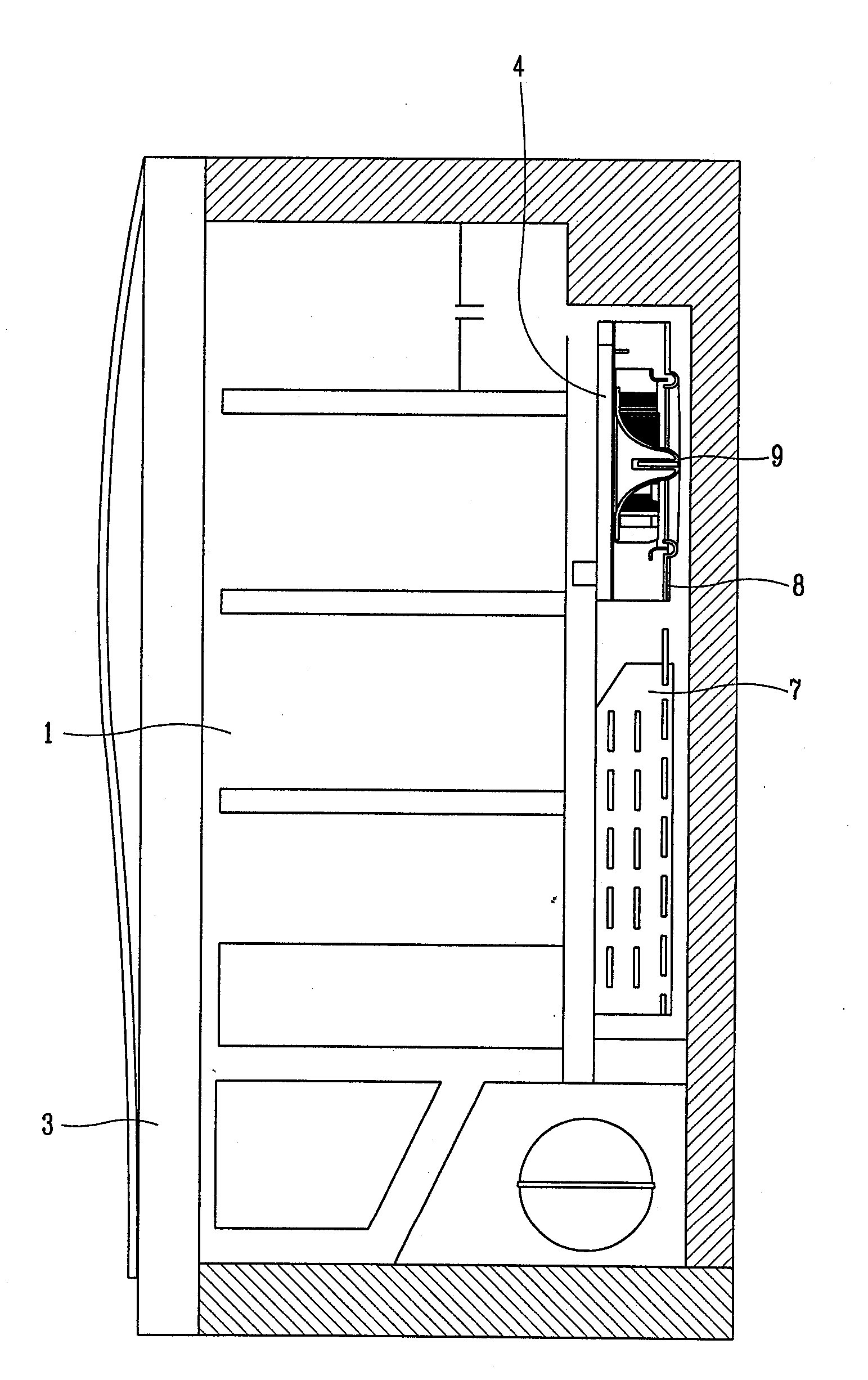

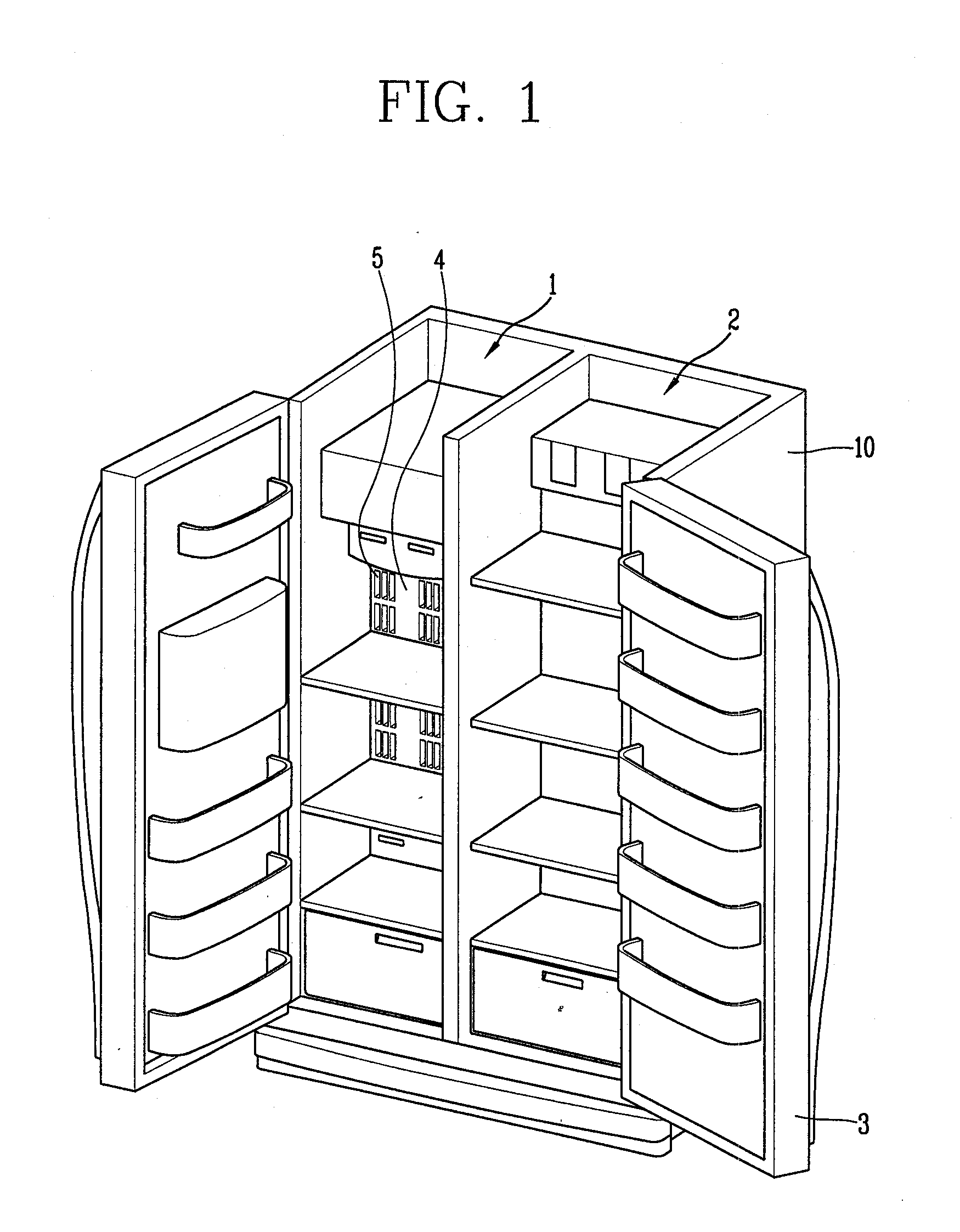

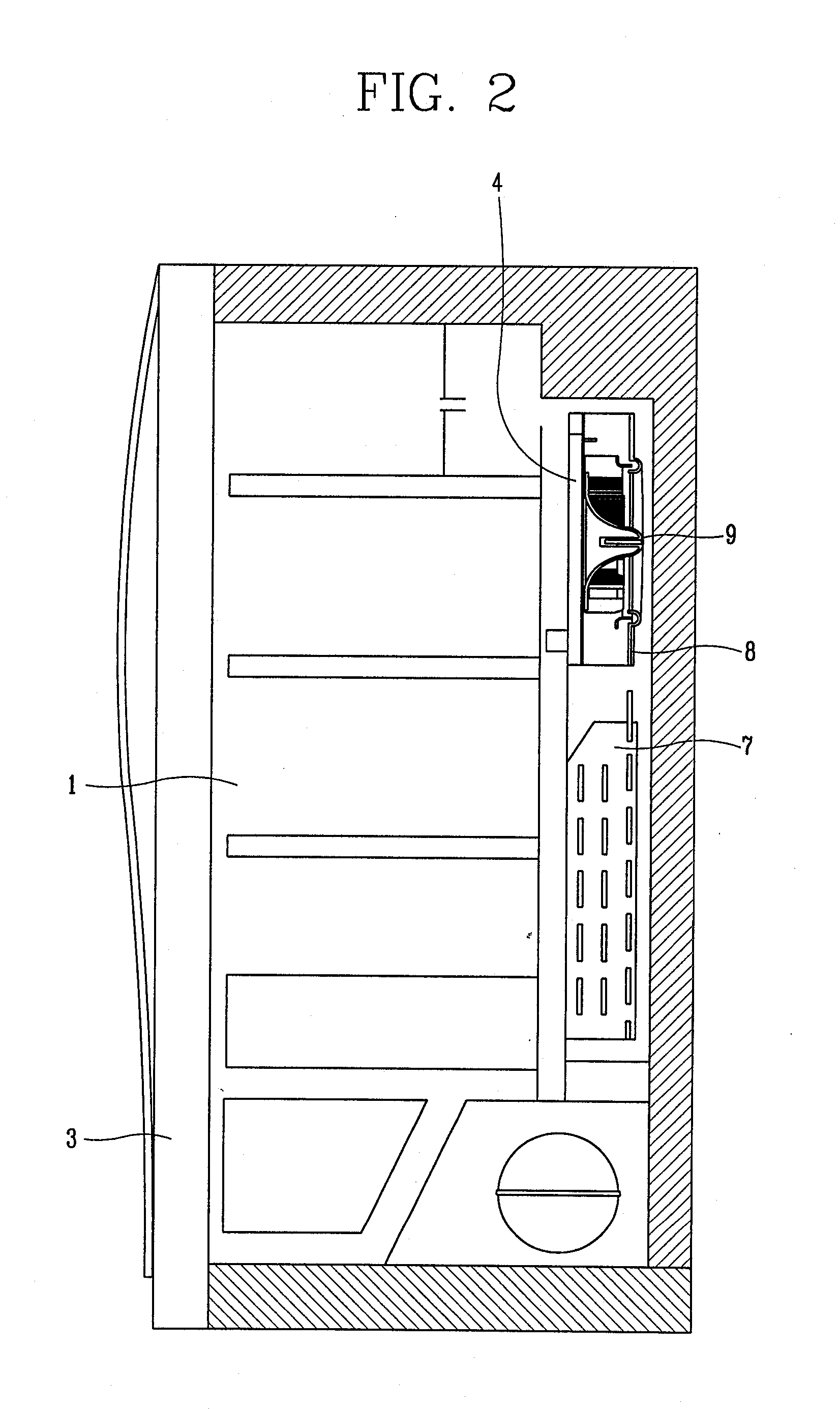

[0034]Hereinafter, a turbofan for blowing and a refrigerator according to the present invention will be explained in more detail.

[0035]As shown in FIGS. 3 to 5, the turbofan for blowing comprises: a base plate 110 of a disc shape having a hub 111 protruding from a center thereof; a plurality of blades 120 disposed on an outer circumerential surface of the base plate 110 with a constant interval therebetween in a circumferential direction, for blowing cool air introduced from the hub 111 in a radial direction; and a shroud 130 connected to the blades 120 in opposition to the base plate.

[0036]A circle that is obtained by connecting outer ends of the respective blades 120 in a radial direction corresponds to an outer circumference of the shroud 130, and is more protruding than an outer circumference of the base plate 110. That is, a diameter (Do) of a circle that is obtained by connecting outer ends of the respective blades 120 is equal to an outer diameter of the shroud 130, but is la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com