Bioresorbable and biocompatible compounds for surgical use

a biocompatible and surgical technology, applied in the field of biocompatible and bioresorbable compounds, can solve the problems of inconvenient use of cross linker agents such as glutaraldehyde in certain applications, insufficient in-vivo biodegradation of collagen, and difficult manipulation of collagen and glycosaminoglycans,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

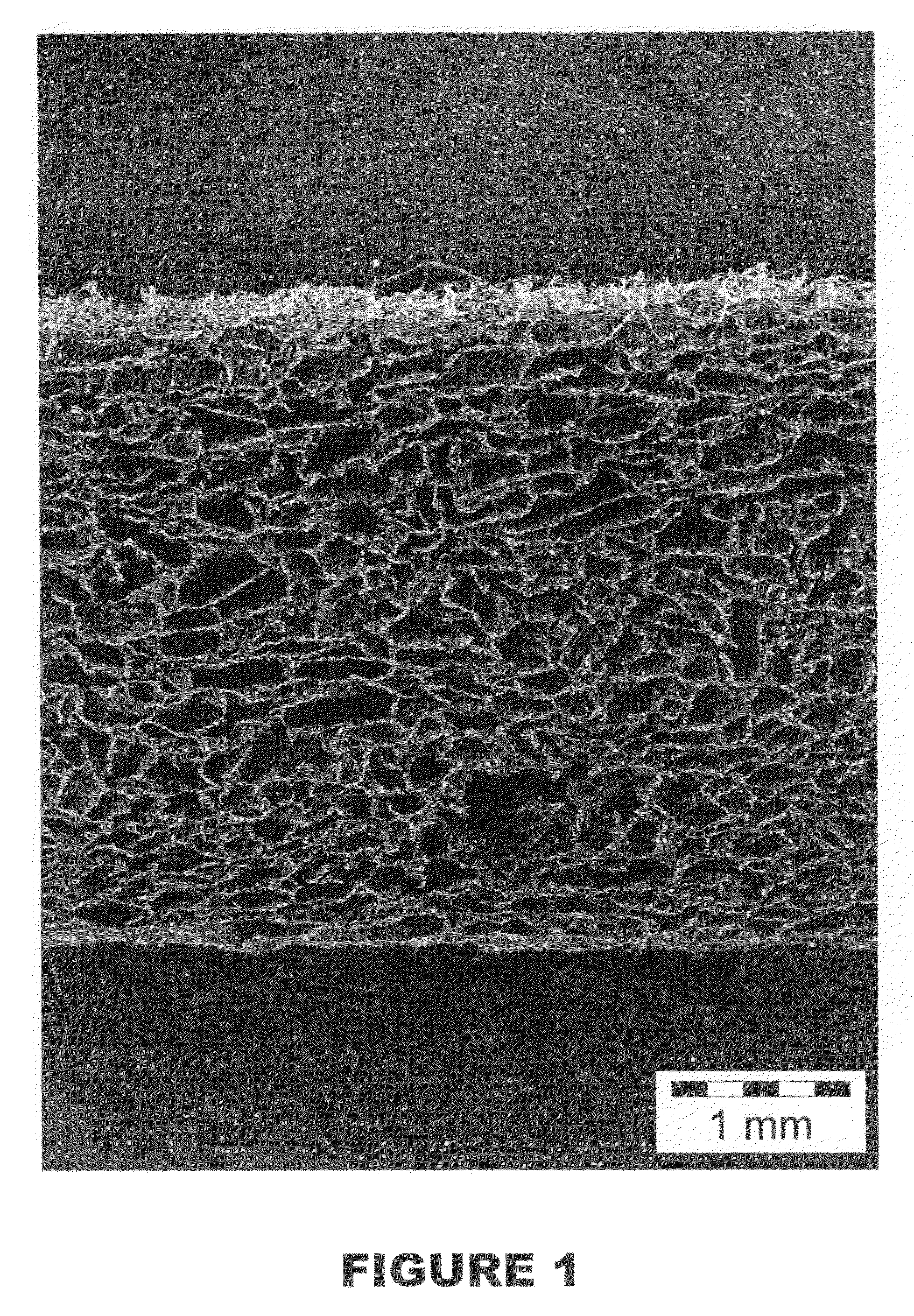

Freeze Dried Sponge for the Preparation of Materials Supporting Cell Growth

[0053]A collagen / chitosan mixture was prepared by mixing an acidic solution of oxidized collagen and an acidic solution of chitosan in different proportions with a final polymer concentration of 1% (w / w).

Oxidized Collagen

[0054]Oxidized collagen was obtained by the oxidation of a 3% collagen solution by periodic acid, at a final concentration of 8 mM, at room temperature, during 3 hours, as described by Bayon, et al. in Example 4 of U.S. Pat. No. 6,596,304. At this step the pH of the oxidized collagen solution was about 3.2.

Native Collagen

[0055]Solutions of native collagen were obtained by solubilizing collagen powder at a 1% final concentration, in sterile water. The pH measured close to 3.

[0056]The chitosan was solubilized in deionized water with a stoechiometric amount of hydrochloric acid with a polymer concentration of 1% (w / w). The pH of the chitosan solution was about 5, but the pH could have be...

example 2

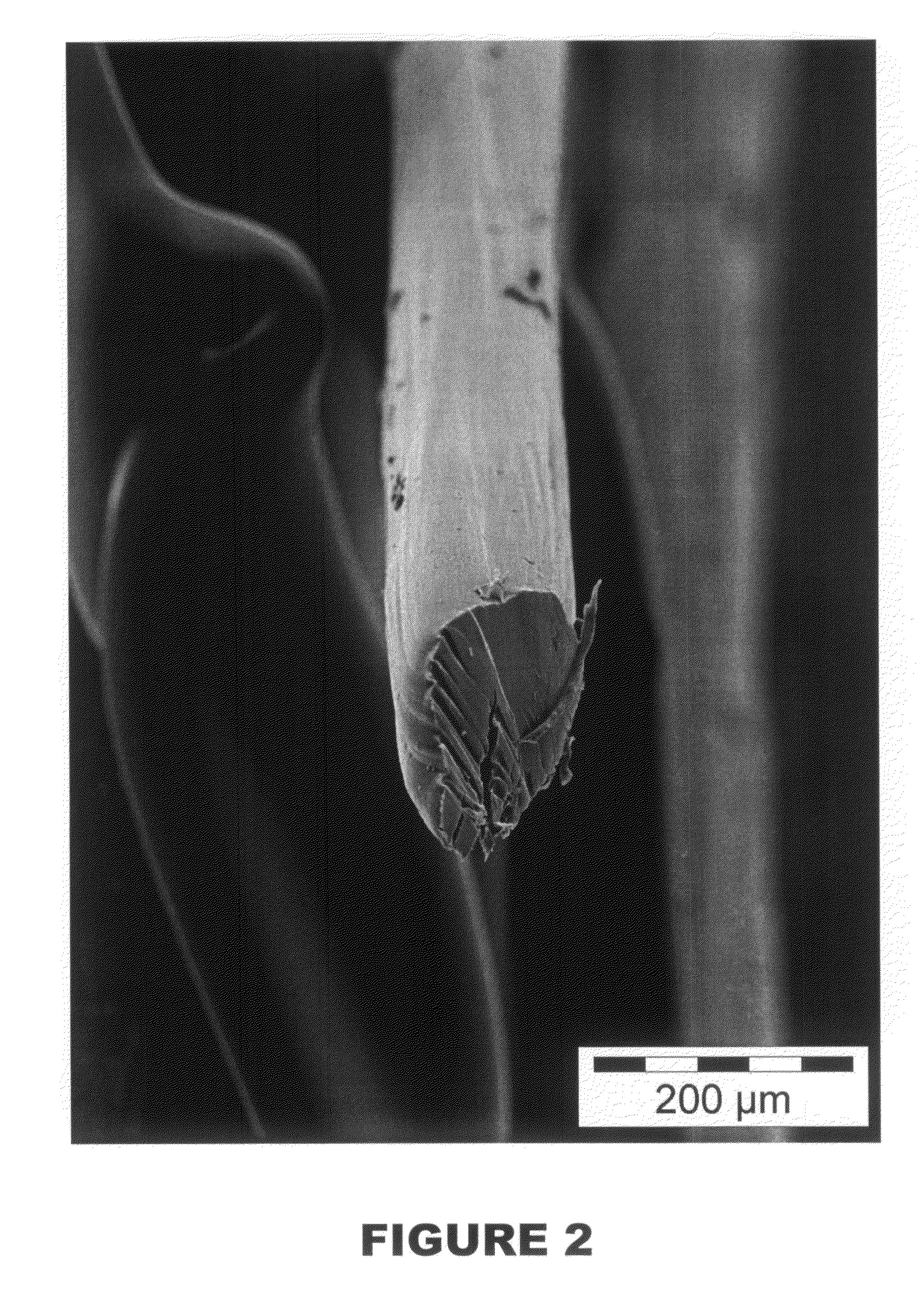

Preparation of Cylindrical Structures for Supporting Nervous Cells Growth

[0066]A collagen / chitosan mixture was prepared by mixing an acidic solution of oxidized collagen and acidic solution of chitosan in different proportions as described above in Example 1, with a final polymer concentration of 2% (w / w).

[0067]The mixture was poured into cylindrical moulds of different diameters ranging from 1 mm to 10 mm and freeze-dried for about 24 hours.

[0068]Thereafter, the cylinders were neutralized in a buffer solution of PBS 1× for about 2 hours and then dried in a ventilated oven at 35° C. overnight.

example 3

Preparation of Tubular Structures for Supporting Endothelial Cells Growth

[0069]A collagen / chitosan mixture was prepared by mixing an acidic solution of oxidized collagen and acidic solution of chitosan in different proportions as described above in Example 1, with a final polymer concentration of 2% (w / w).

[0070]The mixture (about 40 g) was poured into tubular moulds of different diameters ranging from 5 mm to 15 mm and freeze-dried for 24 hours.

[0071]Thereafter, the tubes were neutralized in a buffer solution of PBS 1× for 2 hours and then dried in a ventilated oven at 35° C. overnight.

[0072]Optionally, a 20 / 80 mixture of the oxidized collagen and chitosan with a final polymer concentration of 0.5% (w / w) with a pH adjusted to 5 was used to coat the external surface of the tubular structure bringing different permeability properties to the tubular composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com