Controlled and variable gas phase shifting cryocooler

a cryocooler and variable technology, applied in the field of refrigeration systems, can solve the problems of limiting heat exchange control, cumbersome long tube geometry, heavy weight, bulky, etc., and the inertance tube does not readily provide the means for optimizing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

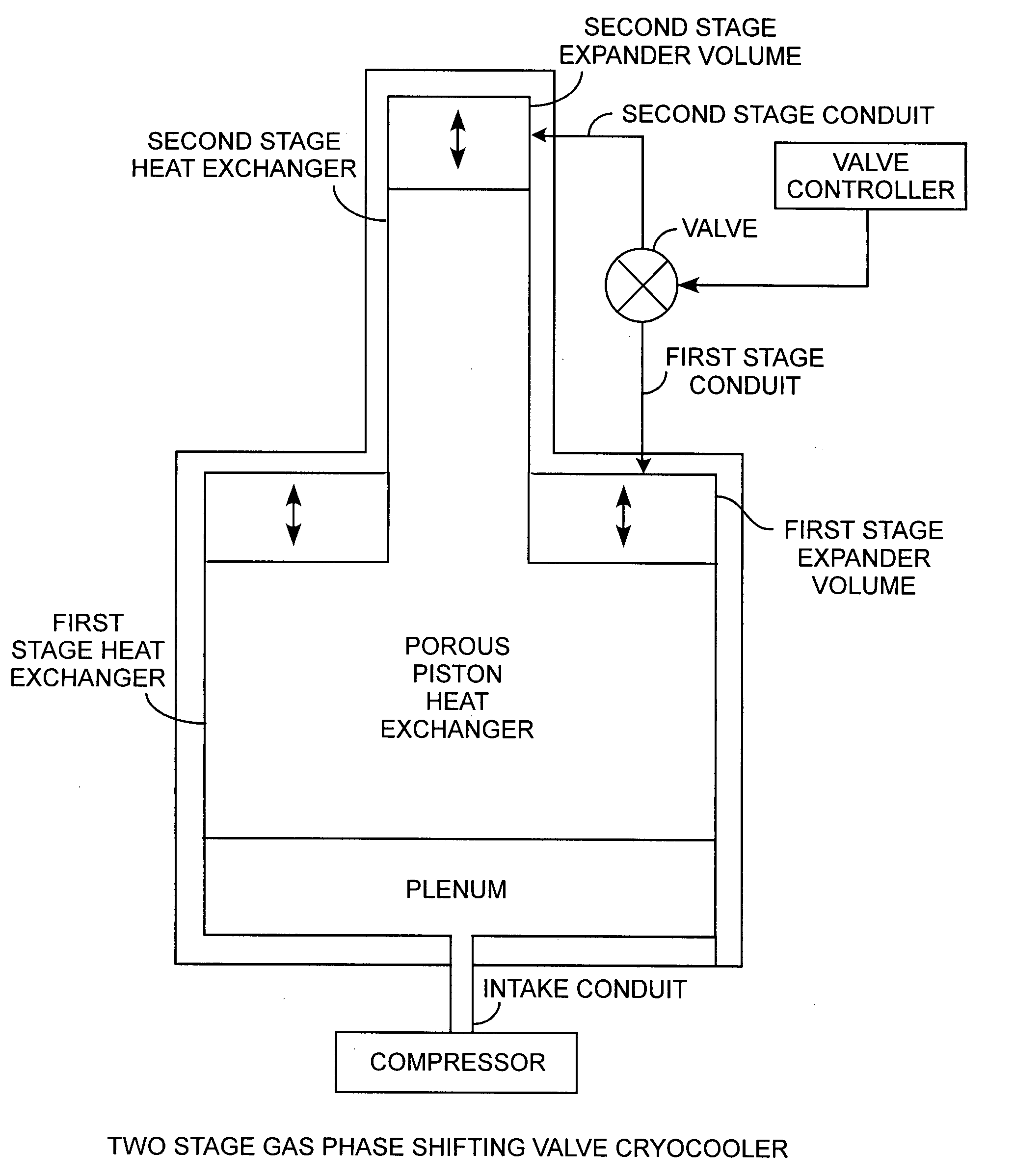

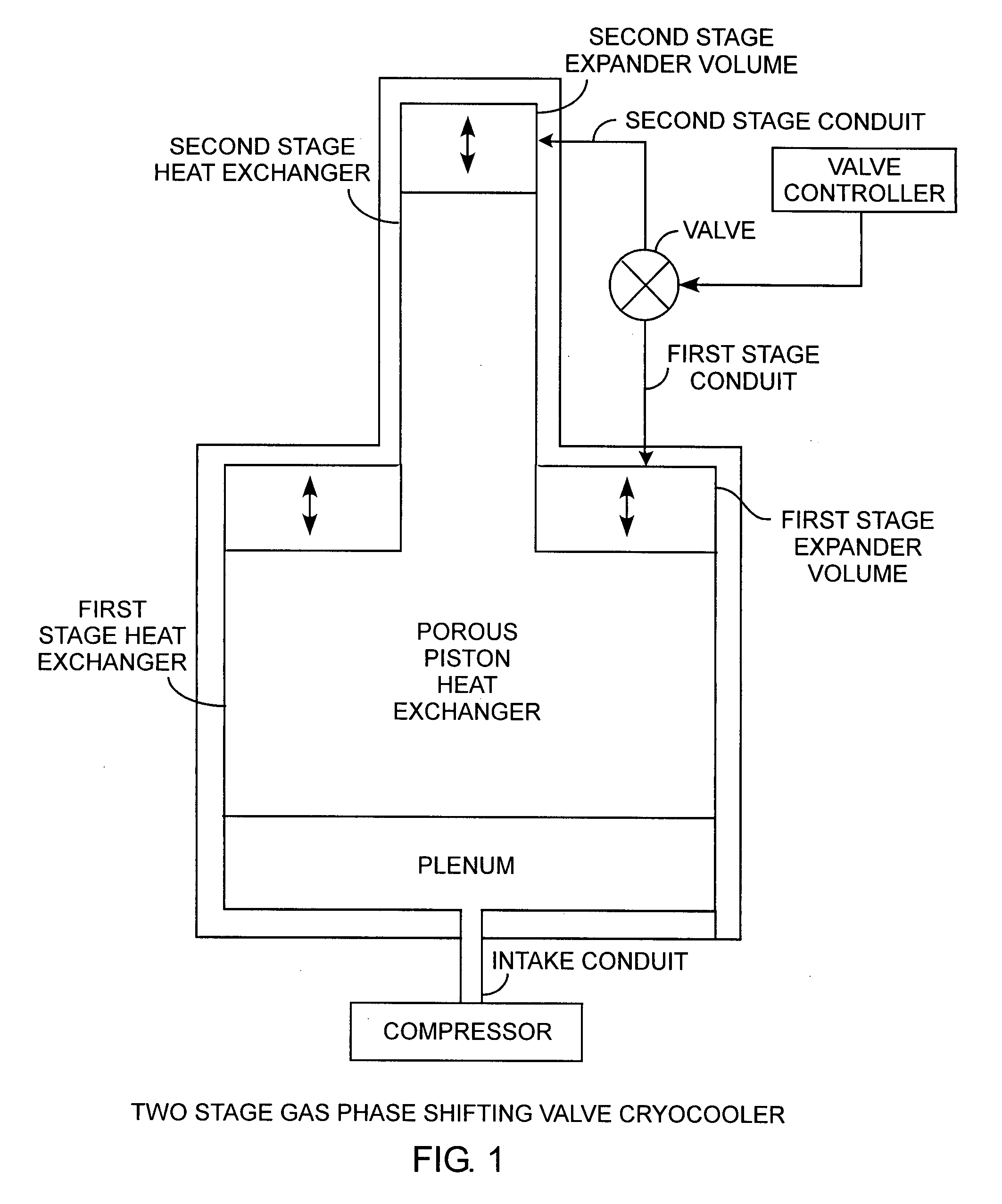

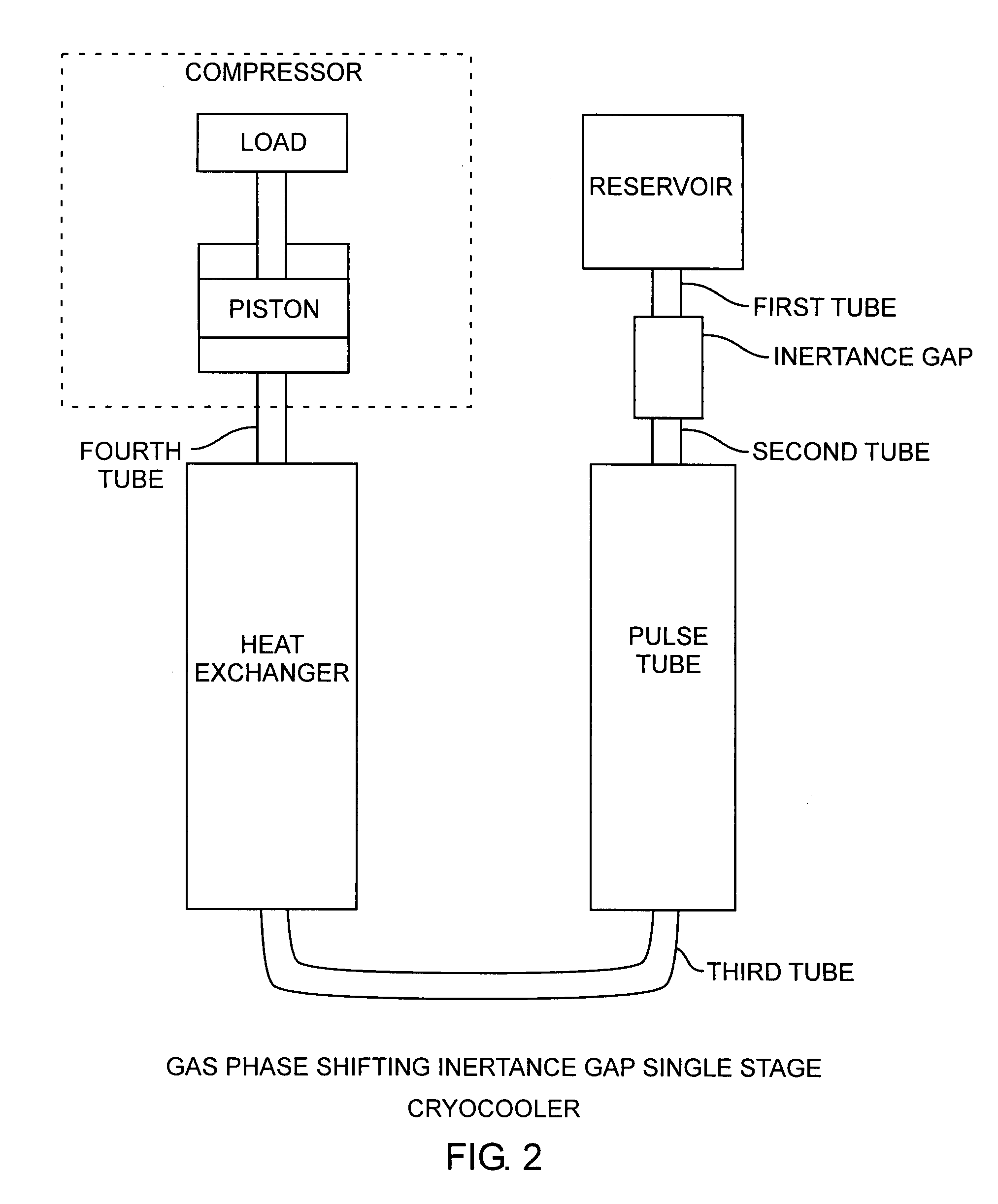

[0023]An embodiment of the invention is described with reference to the figures using reference designations as shown in the figures. Referring to FIG. 1, a two-stage gas phase shifting valve cryocooler is a modified version of a conventional two-stage cooler with a moving porous piston heat exchanger. The porous piston heat exchanger, or simply the regenerator, functions as a heat exchanger. The porous piston is bifurcated for heat exchange into a first stage heat exchanger for exchange heat with a first stage volume and into a second stage heat exchanger for heat exchange with a second stage volume. A compressor provides the pressure and volume work required for cooling, by moving the piston. The compressor injects gas through an intake conduit into an empty volume, known as a plenum. The gas is cooled when passing through the porous heat exchanger. The piston in the cryocooler moves when a parcel of gas is admitted into the plenum through the intake conduit. The parcel of gas the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com