Disk rotor and method of manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017]In one embodiment, a disk rotor having integral airfoils is disclosed. In another embodiment, a method of a manufacturing a disk rotor is disclosed, wherein the airfoils are integral and attached directly to the hub of the disk.

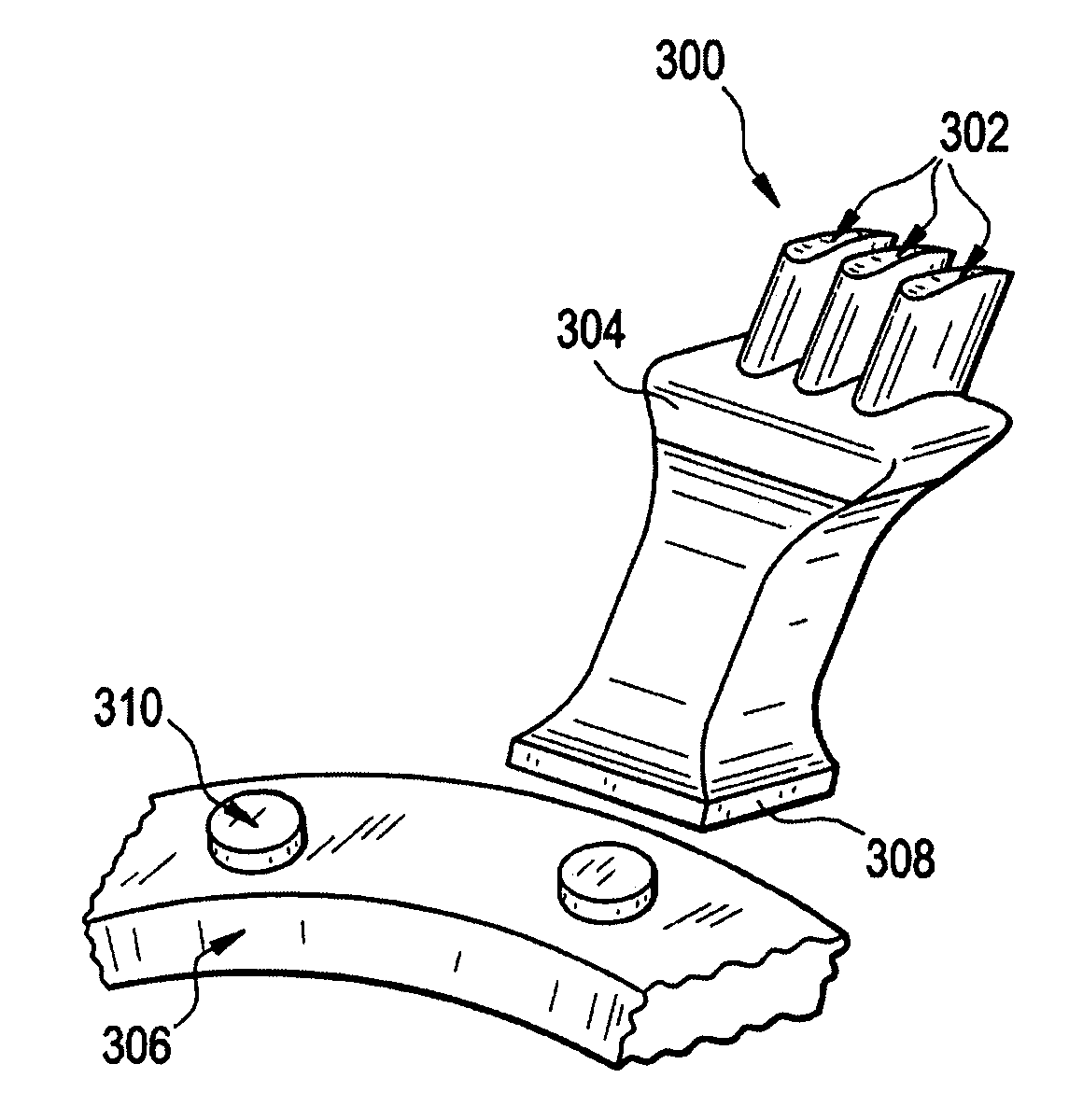

[0018]Referring now to FIG. 3, there is shown a rotor segment 100 of an exemplary embodiment of a disk rotor for use in a compressor or turbine application. The airfoils (i.e., blades) 102 are integral with the spokes 104. As shown in FIG. 3, the airfoil 102 and the spoke 104 form a single part, which can be welded to the hub 106. Each spoke is separated at the typical rim location to transmit airfoil load directly to the hub of the disk rotor.

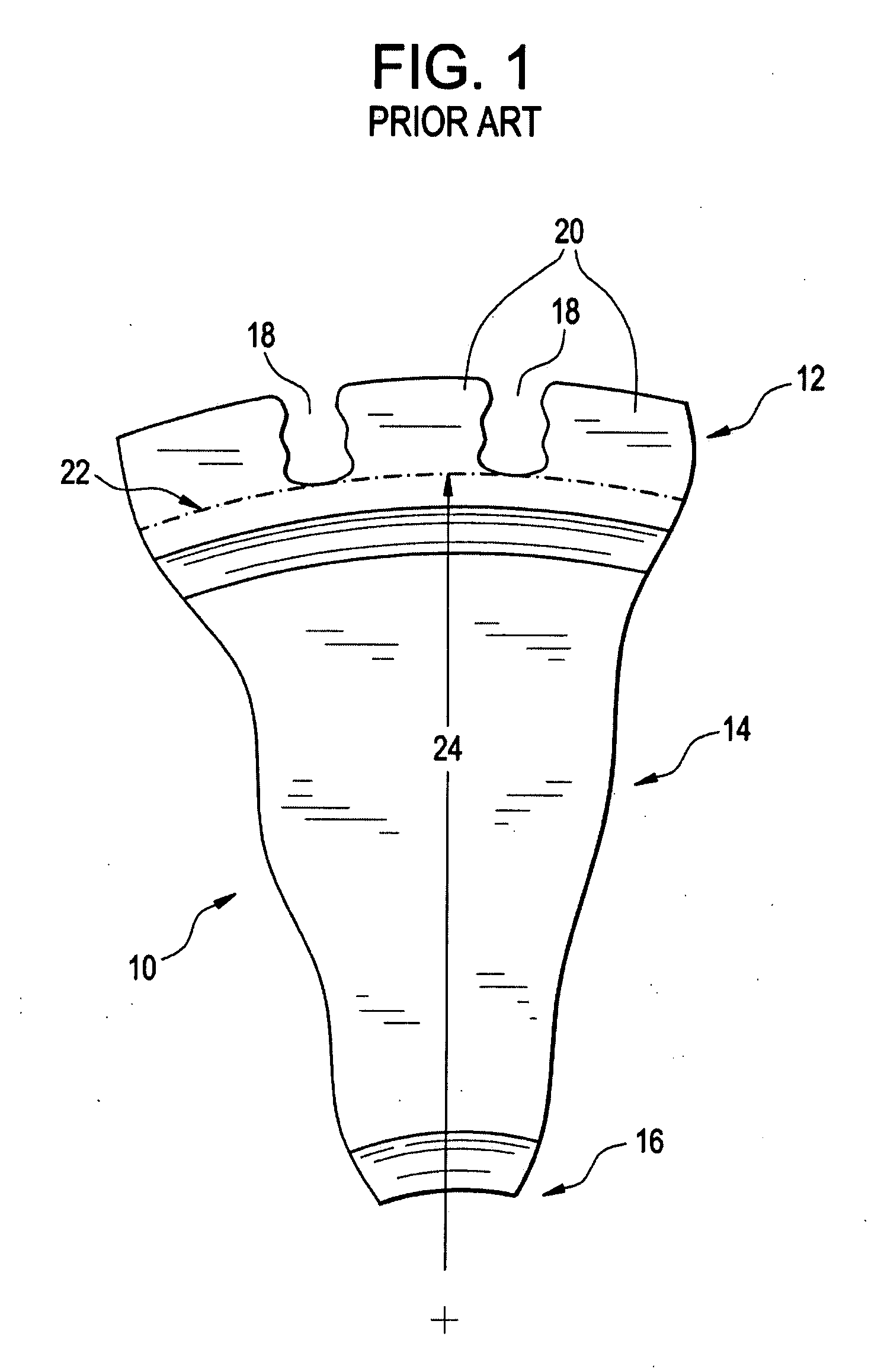

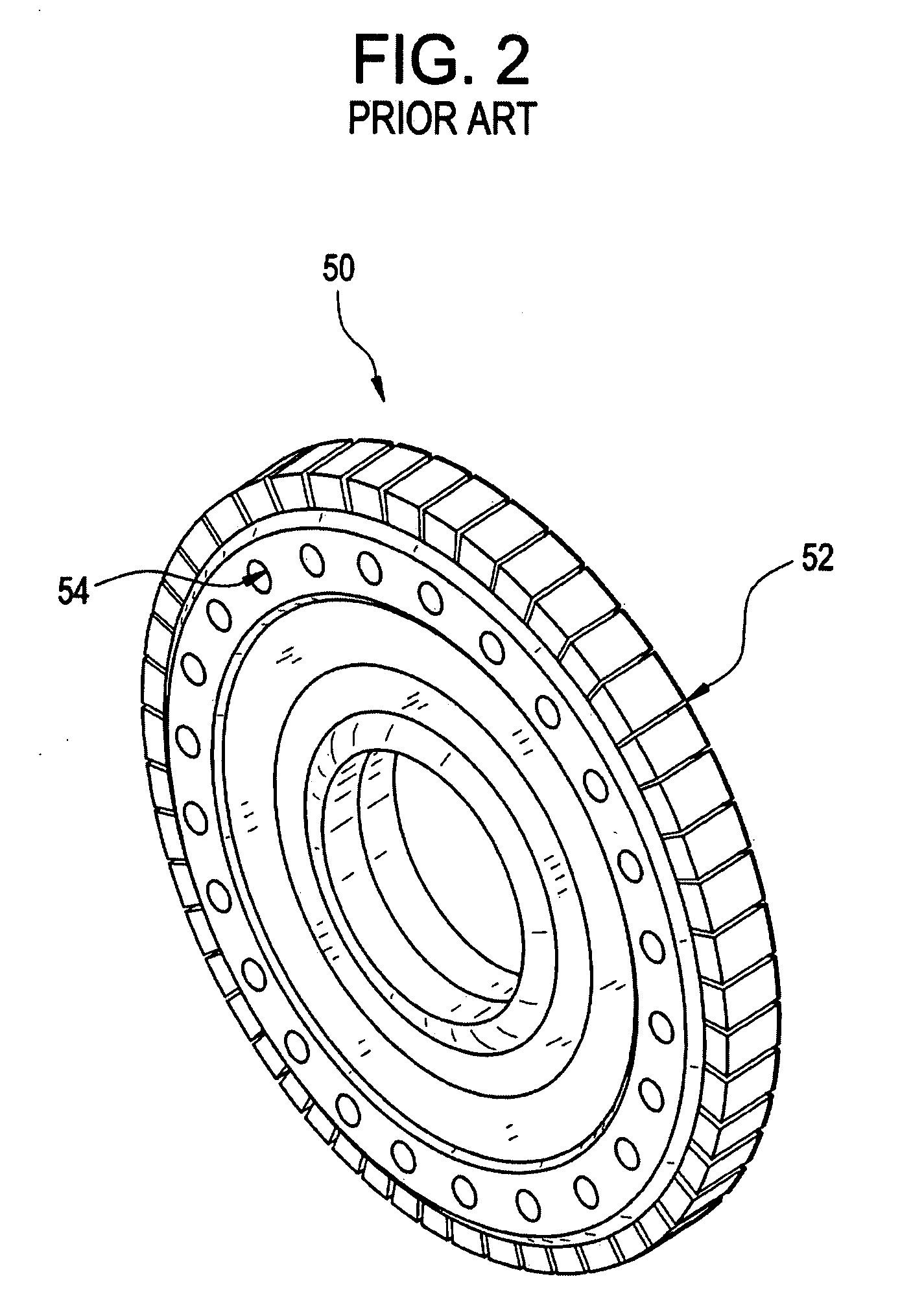

[0019]As described above, current disk rotors comprise a solid rim surrounding a web and a disk hub. The airfoils are then mechanically joined, e.g., by bolting, to attachment slots hollowed out within the rim. The disk rotor as disclosed herein comprises no mechanical attachments between the individual parts. Par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com