Variable Pump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

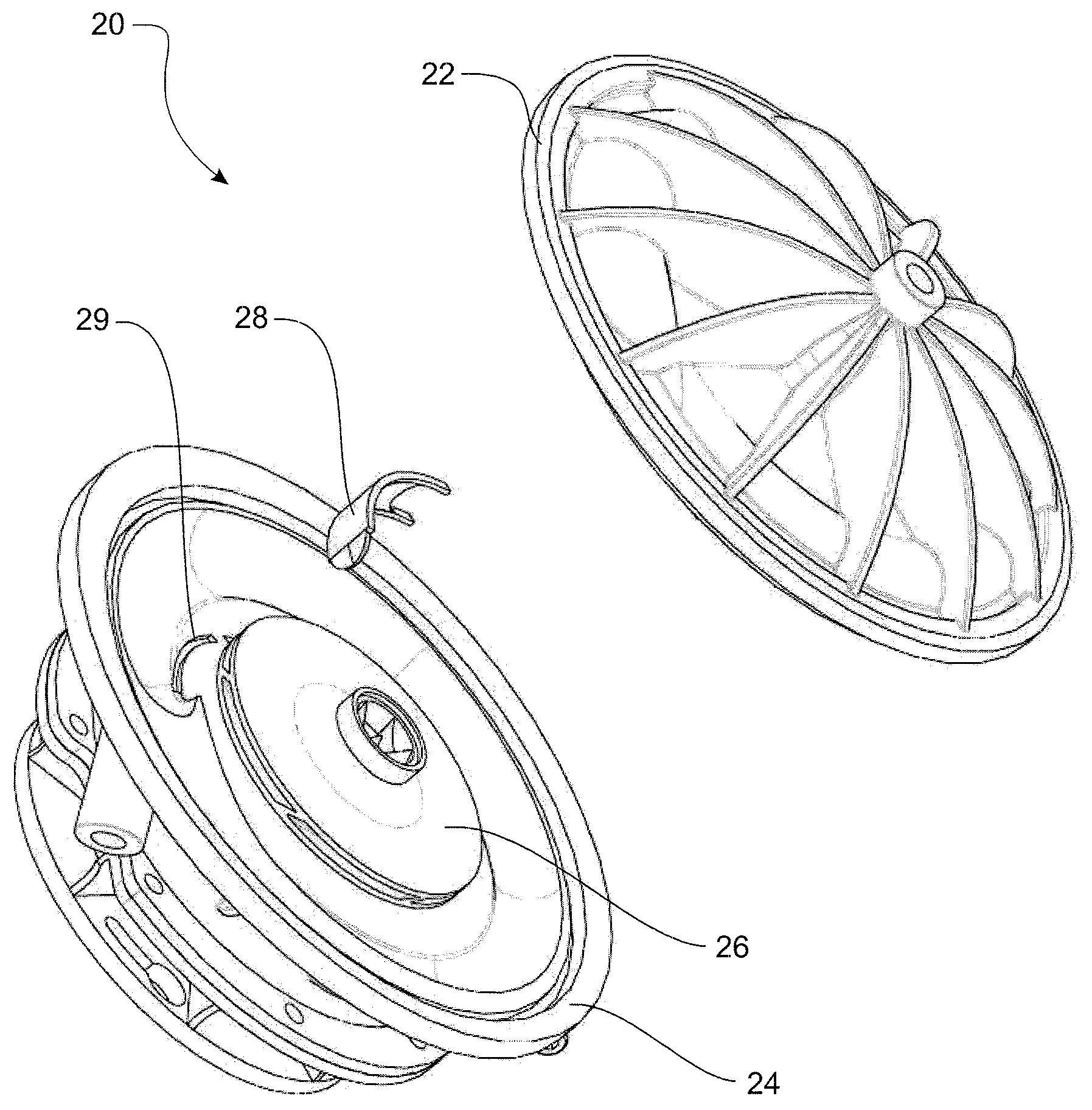

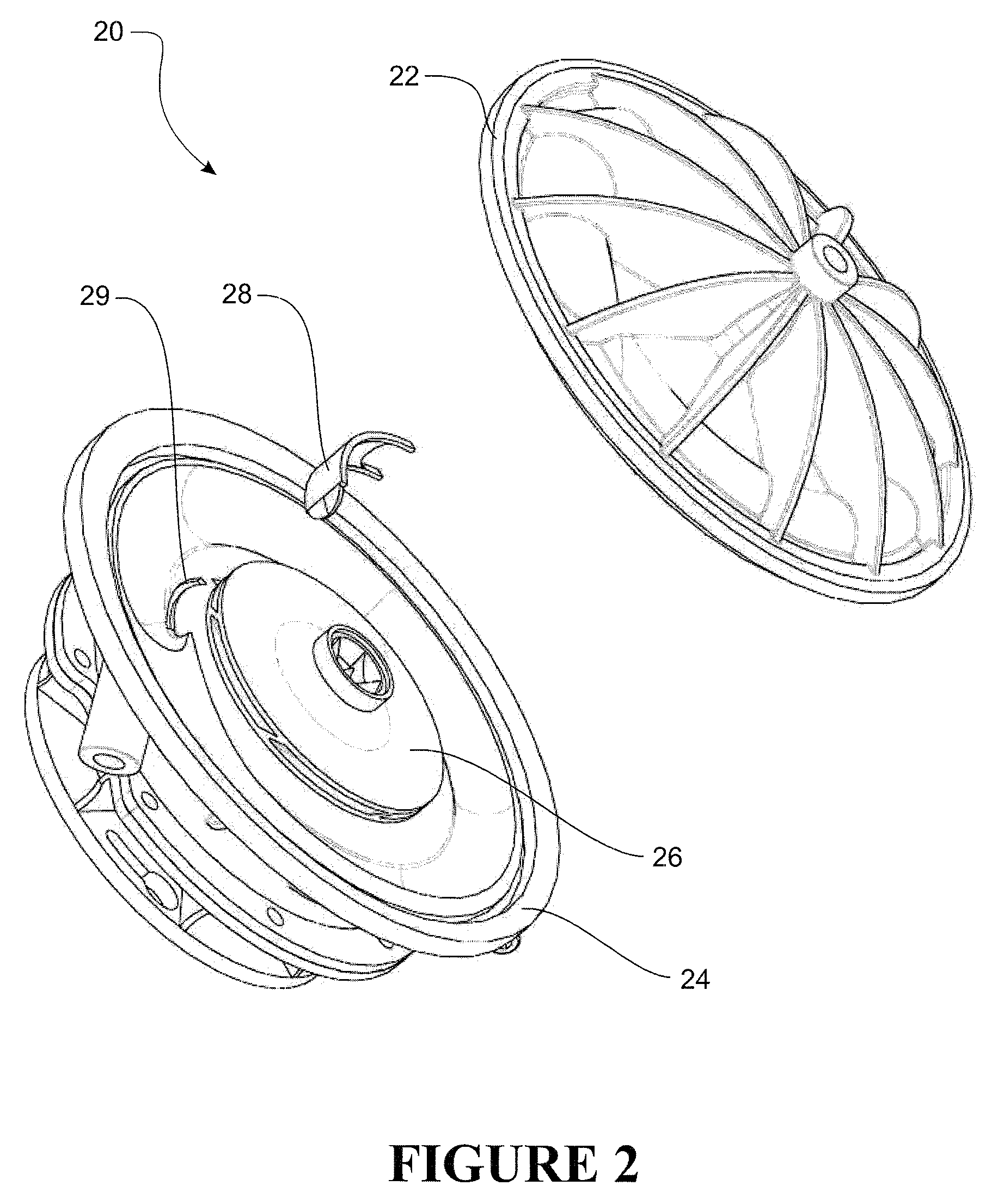

[0032]Referring to FIGS. 2 and 3, the preferred form of the variable pump of the present invention is shown generally as 20. The variable pump 20 comprises two housing halves or casings, a front casing 22 and a back casing 24. When assembled, the front casing 22 and back casing 24 define an interior space in which a removable impeller 26 and a removable cutwater 28 are placed.

[0033]The impeller 26 is received in the pump in any conventional manner, provided it is removable. The cutwater 28 is received in grooves provided in the two housing halves. An example groove is indicated as 29 in the back casing 24 in FIG. 2. A mirrored groove is preferably provided in the front casing 22 so that when the pump is assembled, the cutwater 28 will be firmly secured between the two housing halves. FIG. 3 shows an example mirrored groove 39 in the front casing 22.

[0034]The cutwater 28 is preferably a strip of metal or plastic. A wide range of fixed cutwater sizes may be provided for interchangeabl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap