Gel infused toilet seat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

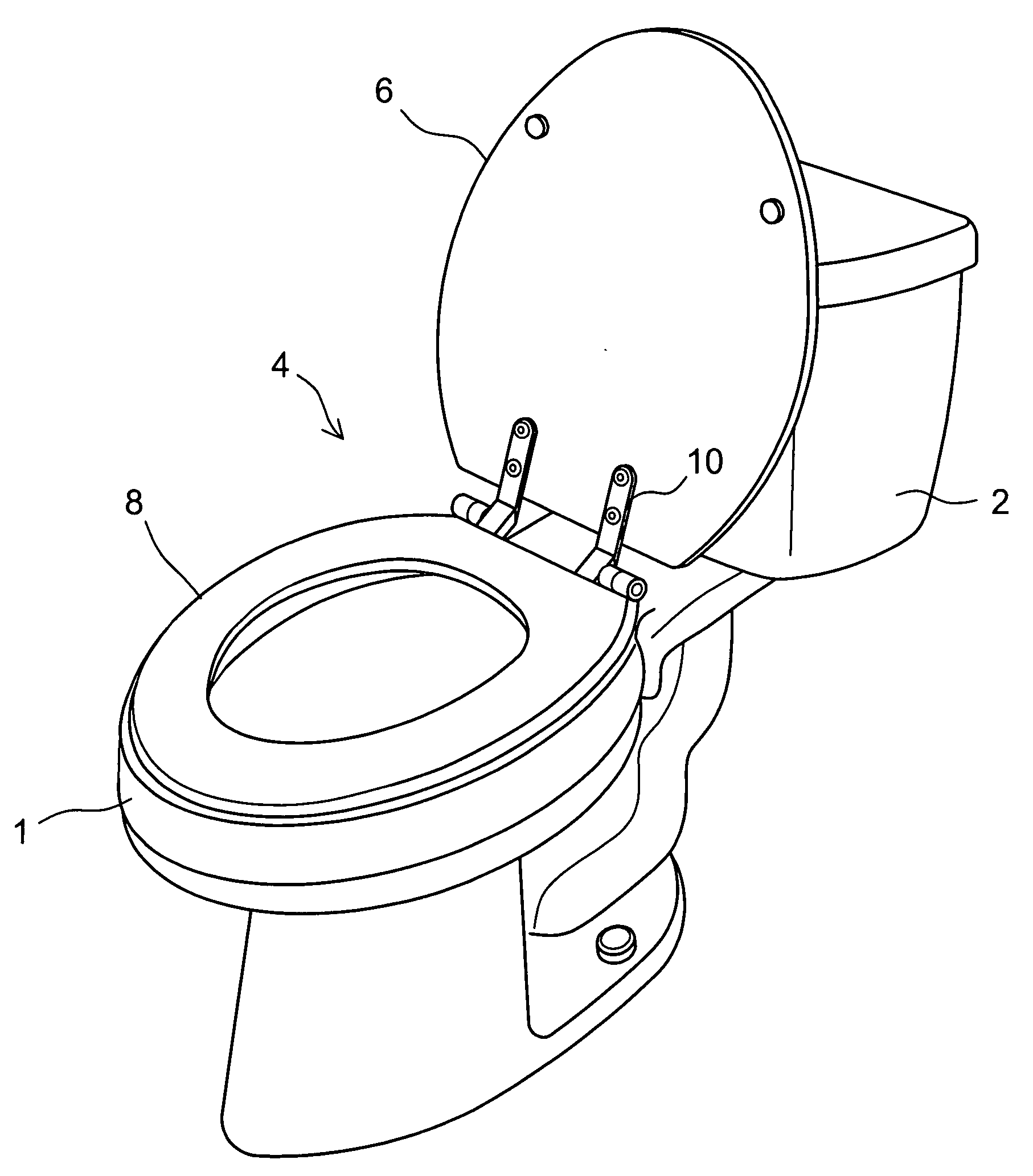

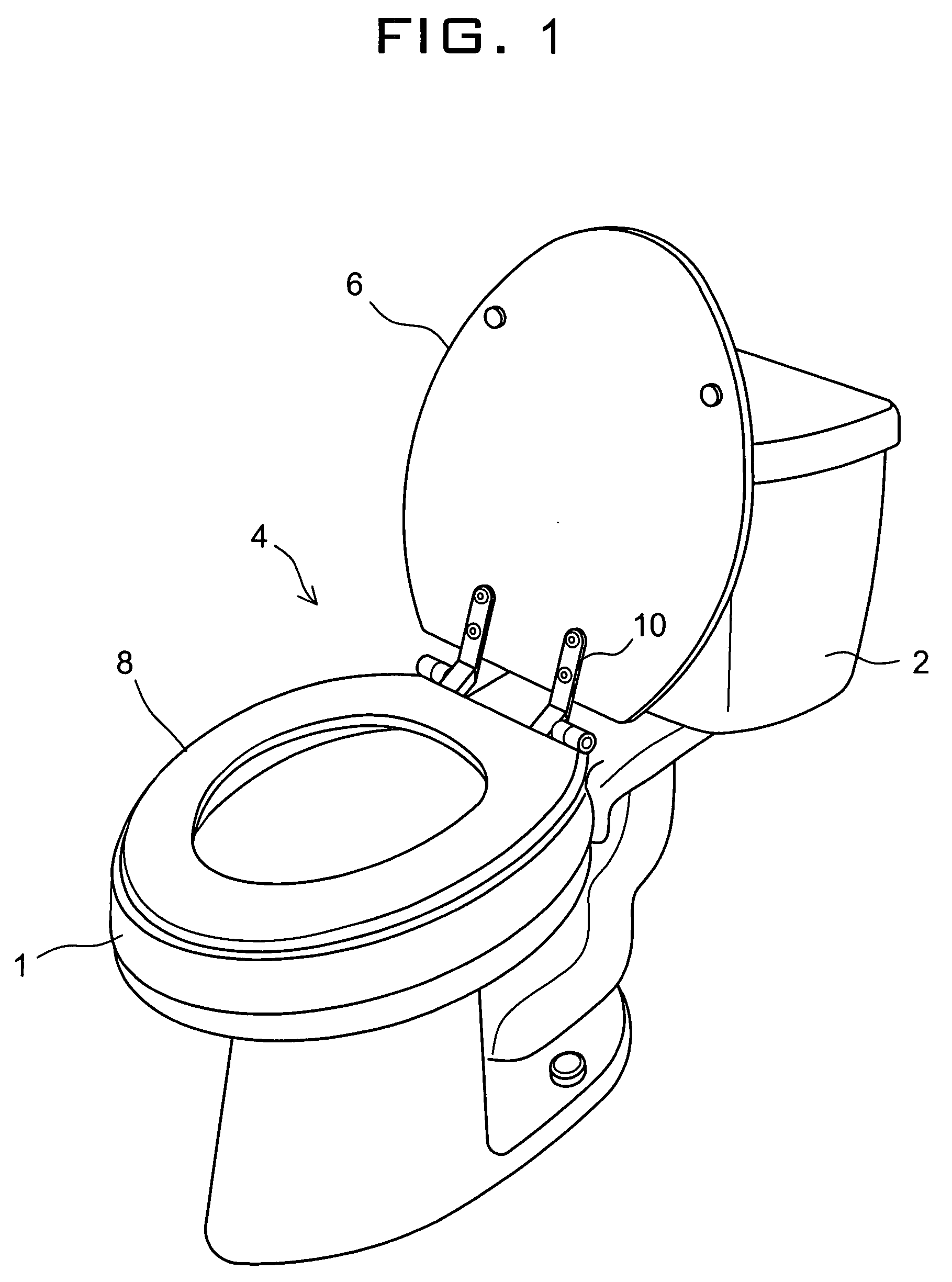

[0040]With reference to FIG. 1, a typical toilet bowl 1 has a pluming portion of a tank 2 in the back and a front seating portion 4 that comprises a hinged assembly of a plastic or wooden lid 6 and a seat 8 made in accordance with the present invention. Two hinge sections 10 may be of any known types that mount the lid 6 and seat 8 to pivot independently of each other on a rear portion of bowl 1.

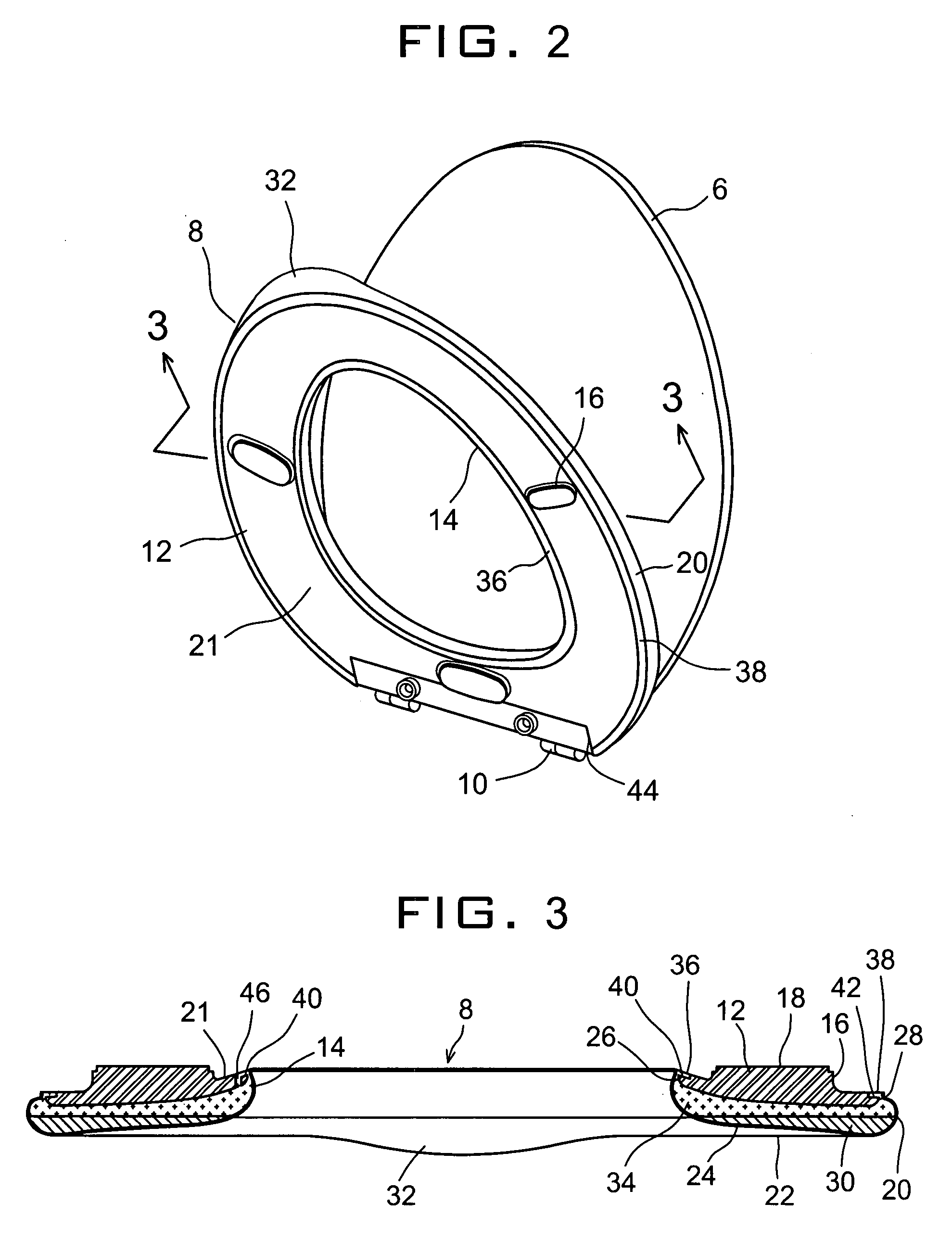

[0041]In FIG. 2, seat 8 of the present invention is raised to show a firm base section 12 exposed at the bottom of seat 8. Base section 12 is shaped generally in an oval ring although it may be made into a C-shape or so called open front less cover type. An elliptical central opening 14 of seat 8 is arranged to overlie the bowl 1. Three or more support strips 16 may be formed integral to base section 12, which may be made of polypropylene (PP) by an injection molding and then it is joined by multiple top layers to give unique characteristics to the seat 1 of the present invention.

[0042]Refer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

| Flexibility | aaaaa | aaaaa |

| Moldable | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com