Docking and Drilling Stations for Running Self-Standing Risers and Conducting Drilling, Production and Storage Operations

a technology for drilling stations and risers, applied in the field of offshore facilities, can solve the problems of significant delays in many drilling projects, shortfall of offshore drilling units called mobile offshore drilling units, and dramatic increase in the cost of obtaining either a new or existing modu for exploration and production operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019]The description that follows includes exemplary systems, methods, and techniques that embody various aspects of the presently inventive subject matter. However, it will be readily understood by those of skill in the art that the disclosed embodiments may be practiced without one or more of these specific details. In other instances, well-known manufacturing equipment, protocols, structures and techniques have not been shown in detail in order to avoid obfuscation in the description.

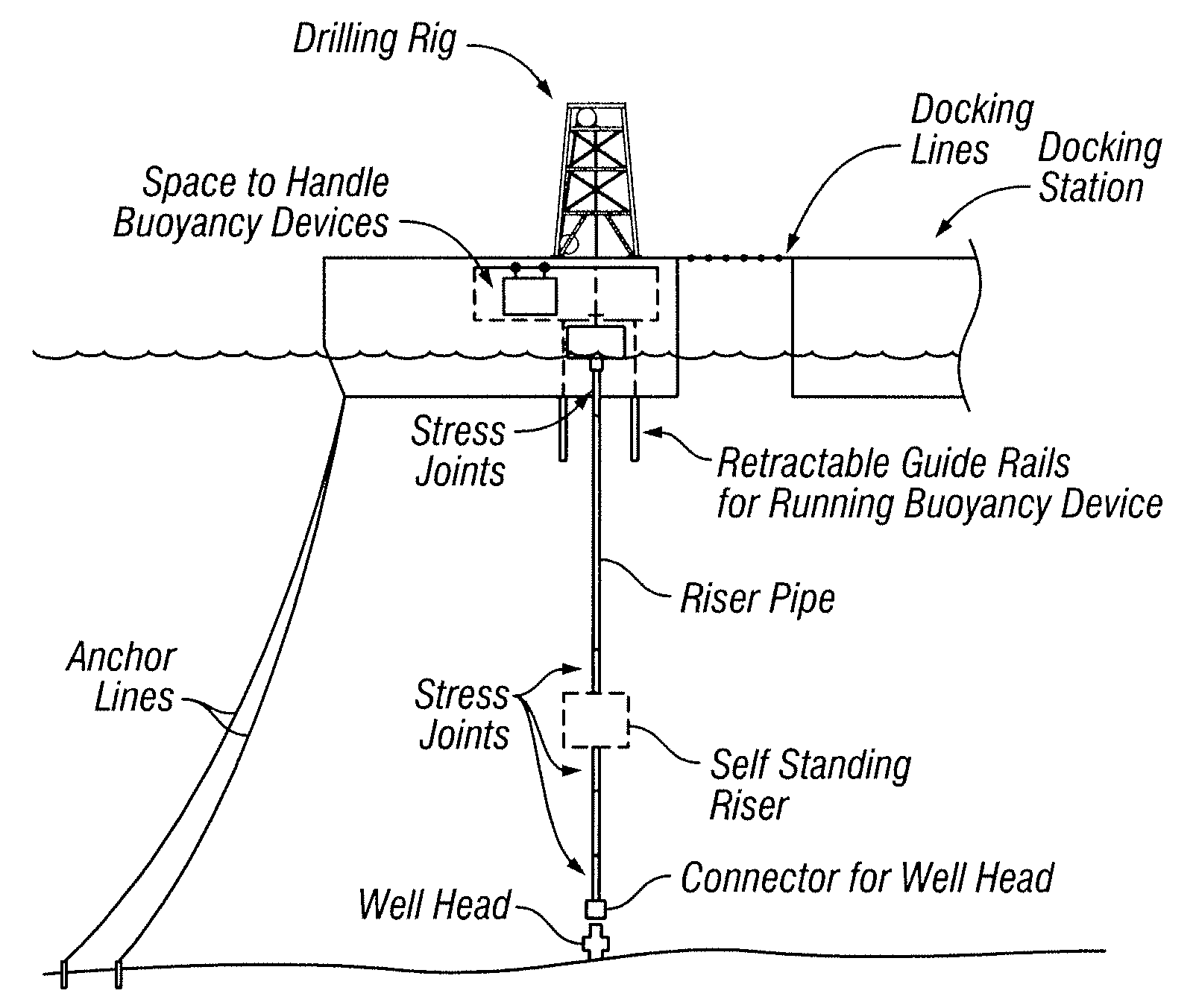

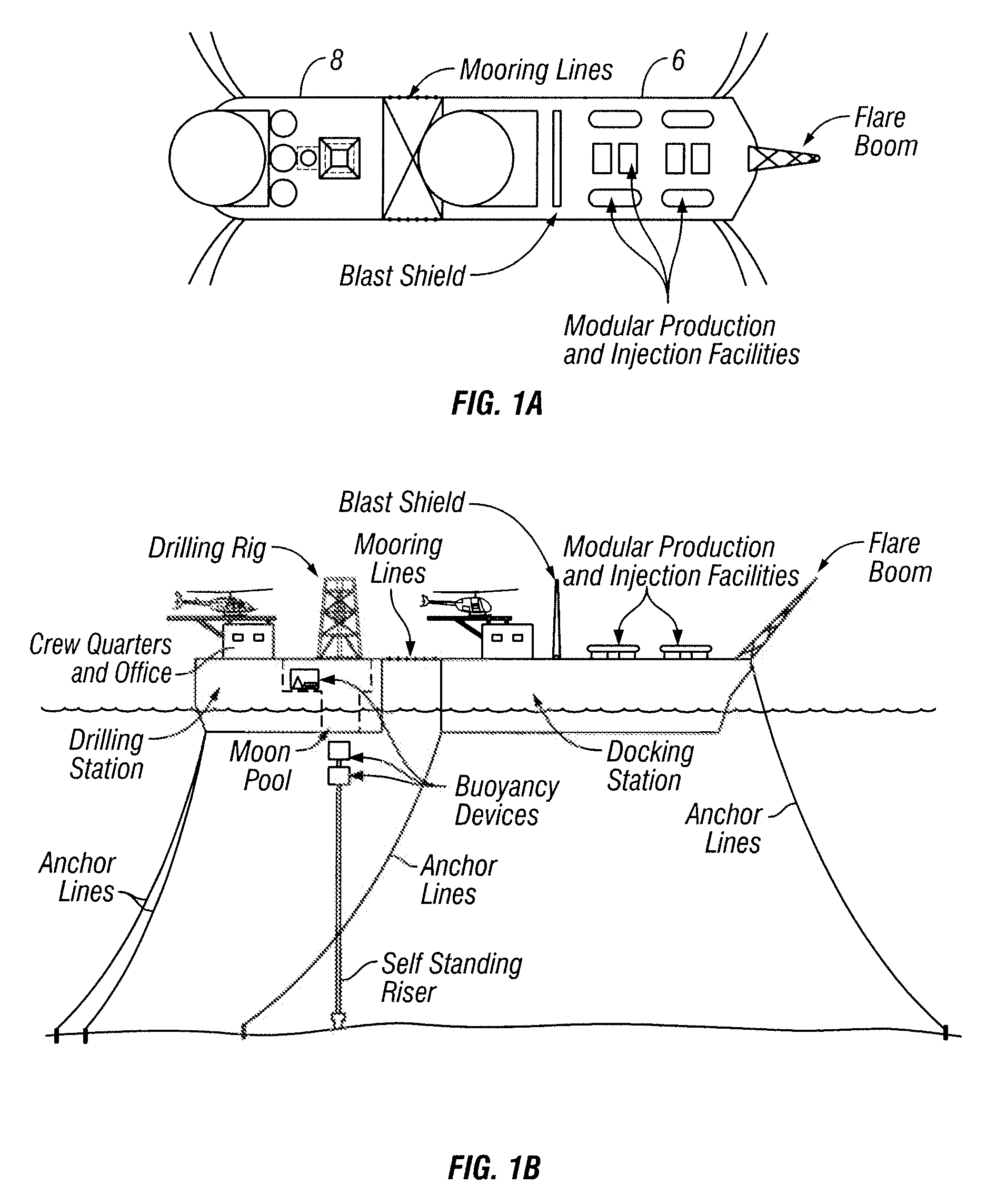

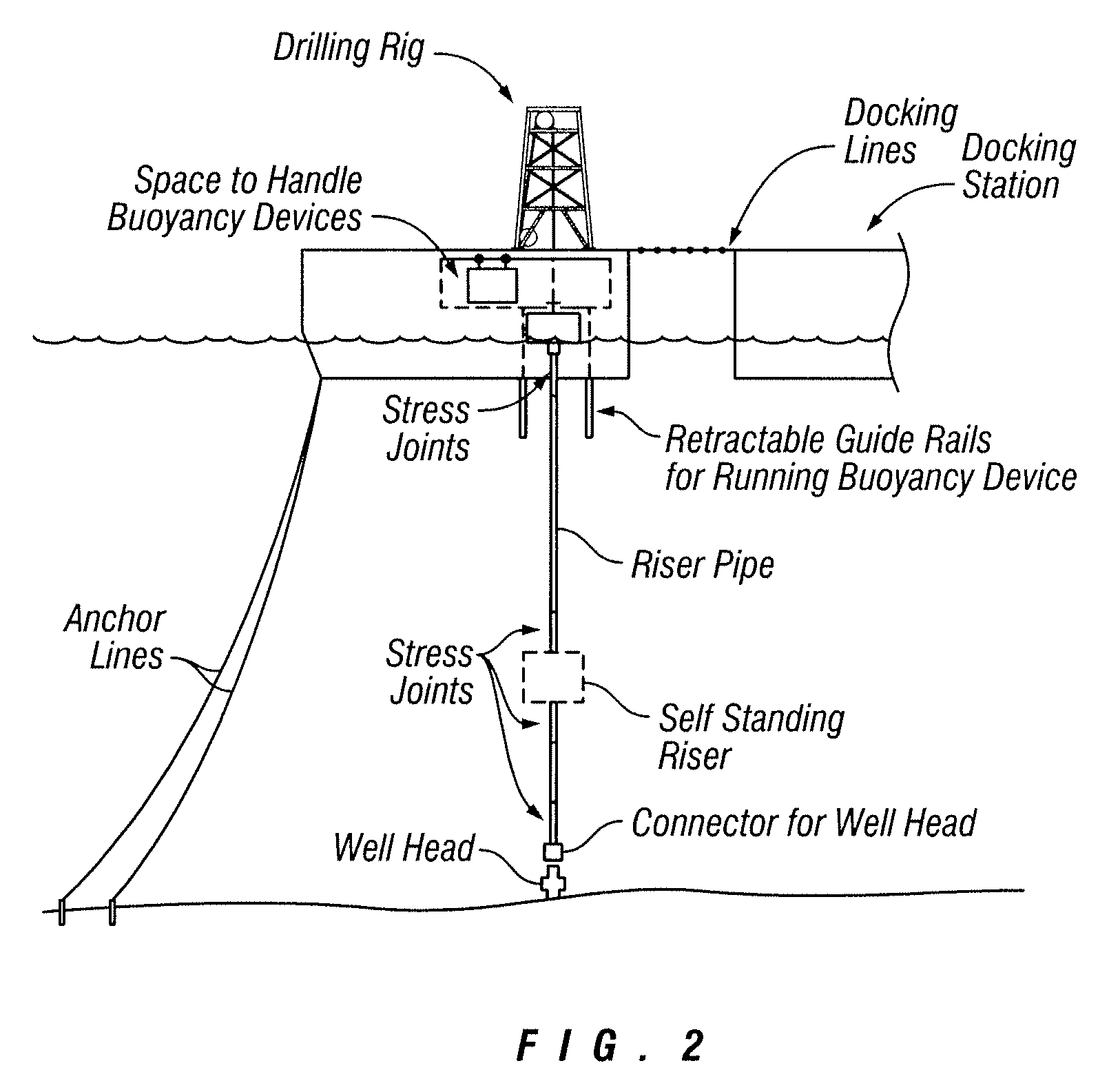

[0020]Referring now to the example embodiment illustrated in FIG. 1A, an overhead view of a docking station 6 and a drilling station 8 are depicted as being moored together in an end-to-end manner. The embodiment of the drilling station shown in FIG. 1B comprises crew quarters and an operations office; a drilling rig; a void space designed for housing and deploying various buoyancy devices; a helipad; a moon pool; a plurality of anchor lines used to anchor the system to an associated seabed; and moo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com