Insulation for Above Ground Swimming Pools

a technology for swimming pools and insulation materials, applied in solar heat devices, solar collectors for particular environments, sustainable buildings, etc., can solve the problems of not being considered necessary or possible to attach insulation to the walls of above ground pools, and achieve the effects of reducing the risk of injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

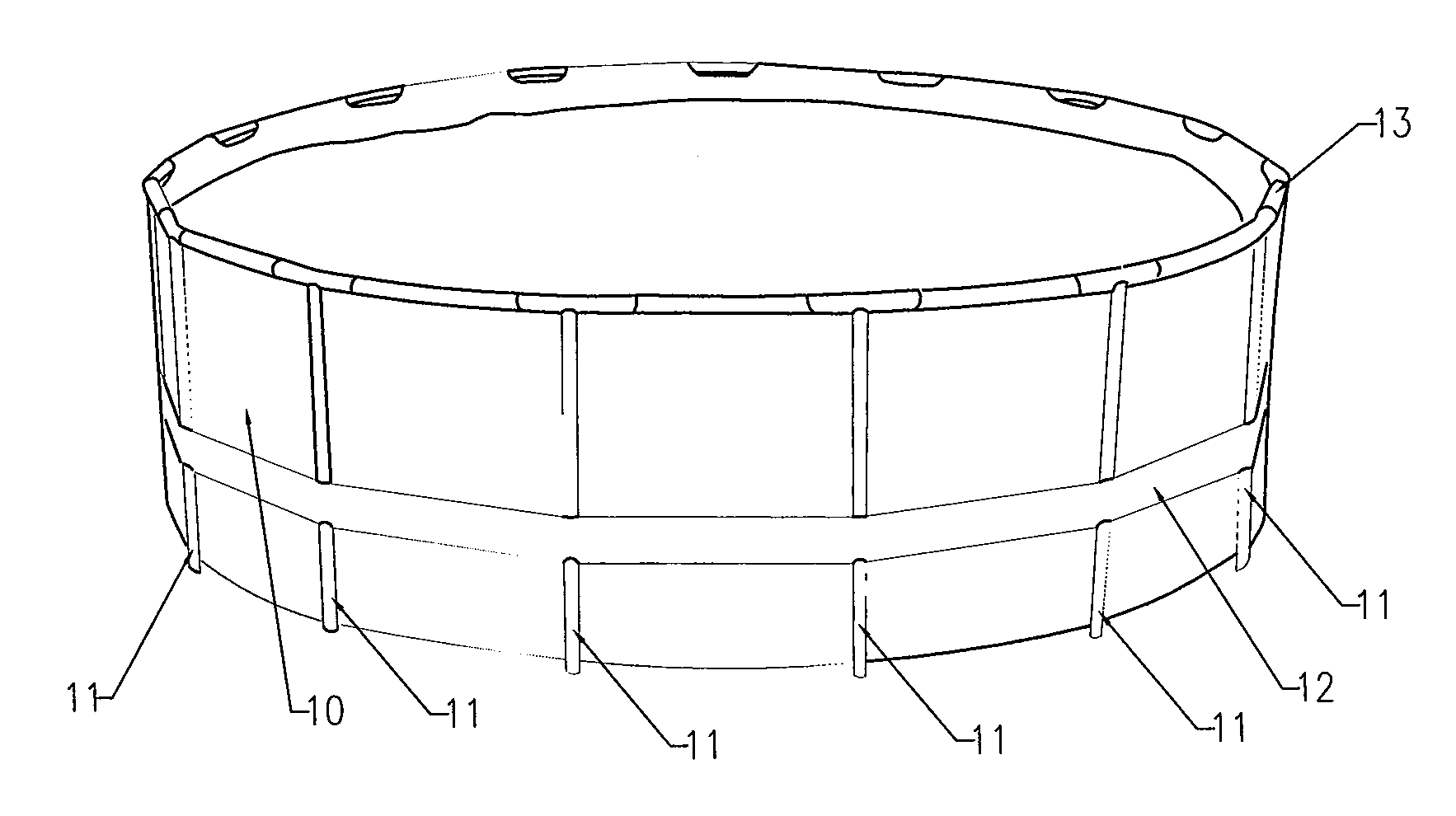

[0017]FIGS. 1, 2 and 3 show particular embodiments of plastic liner pools supported by a metal frame. In FIG. 1 a round one piece plastic liner 10 is held up by a multiplicity of metal support legs 11 which are constrained to move by a broad leg support band of plastic 12. The legs locate into a top rail assembly 13. The support legs remain close to the pool wall apart from a region above the broad band of plastic 12 and the top rail assembly 13 where there is a significant air gap.

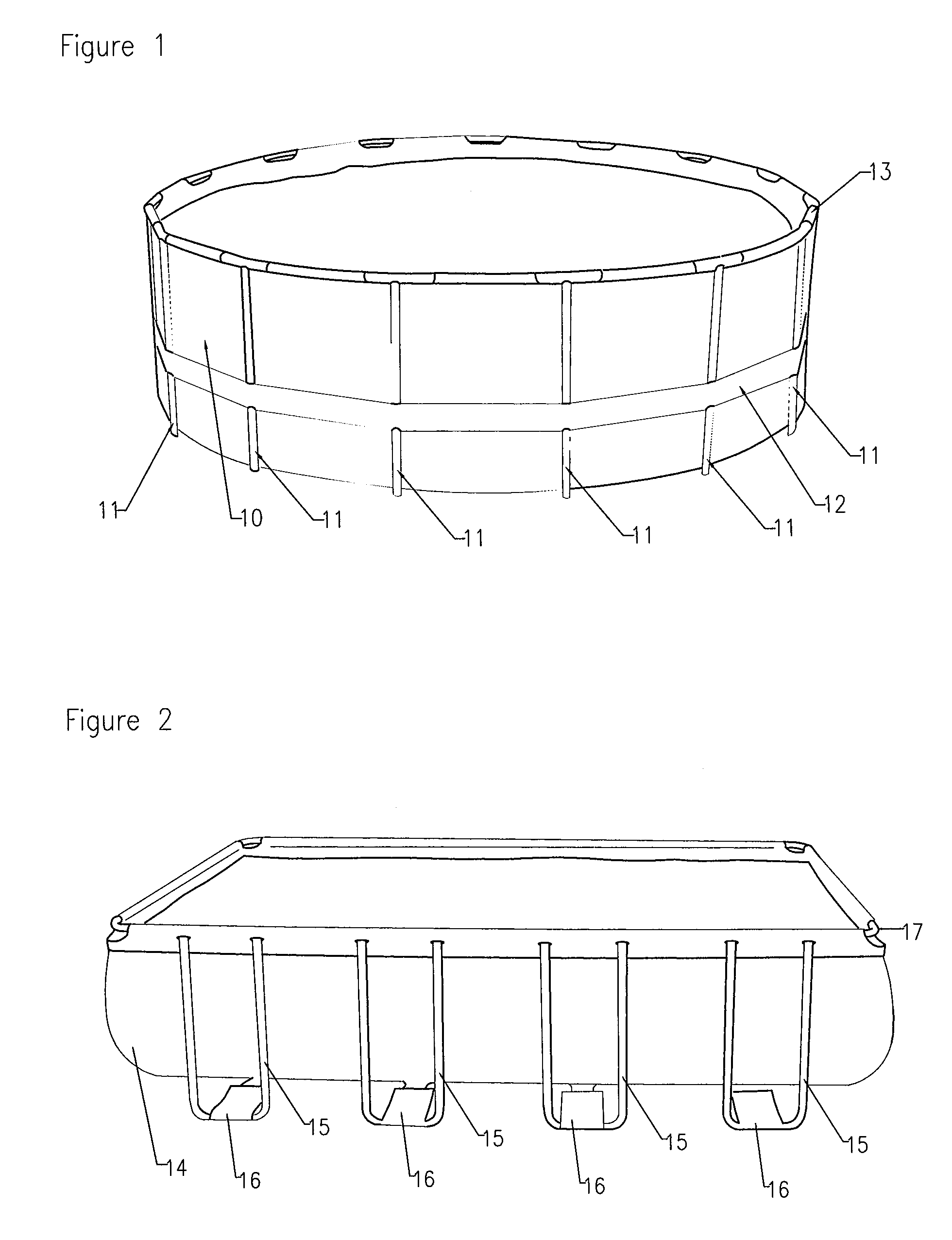

[0018]FIG. 2 is a one piece rectangular liner 14, supported by a number of leg assemblies 15, which are tied back to the liner by braces 16. The leg assemblies locate in a top rail assembly 17. The leg assemblies are in close proximity to the plastic liner except in the region of the braces 16 where this is a substantial air gap.

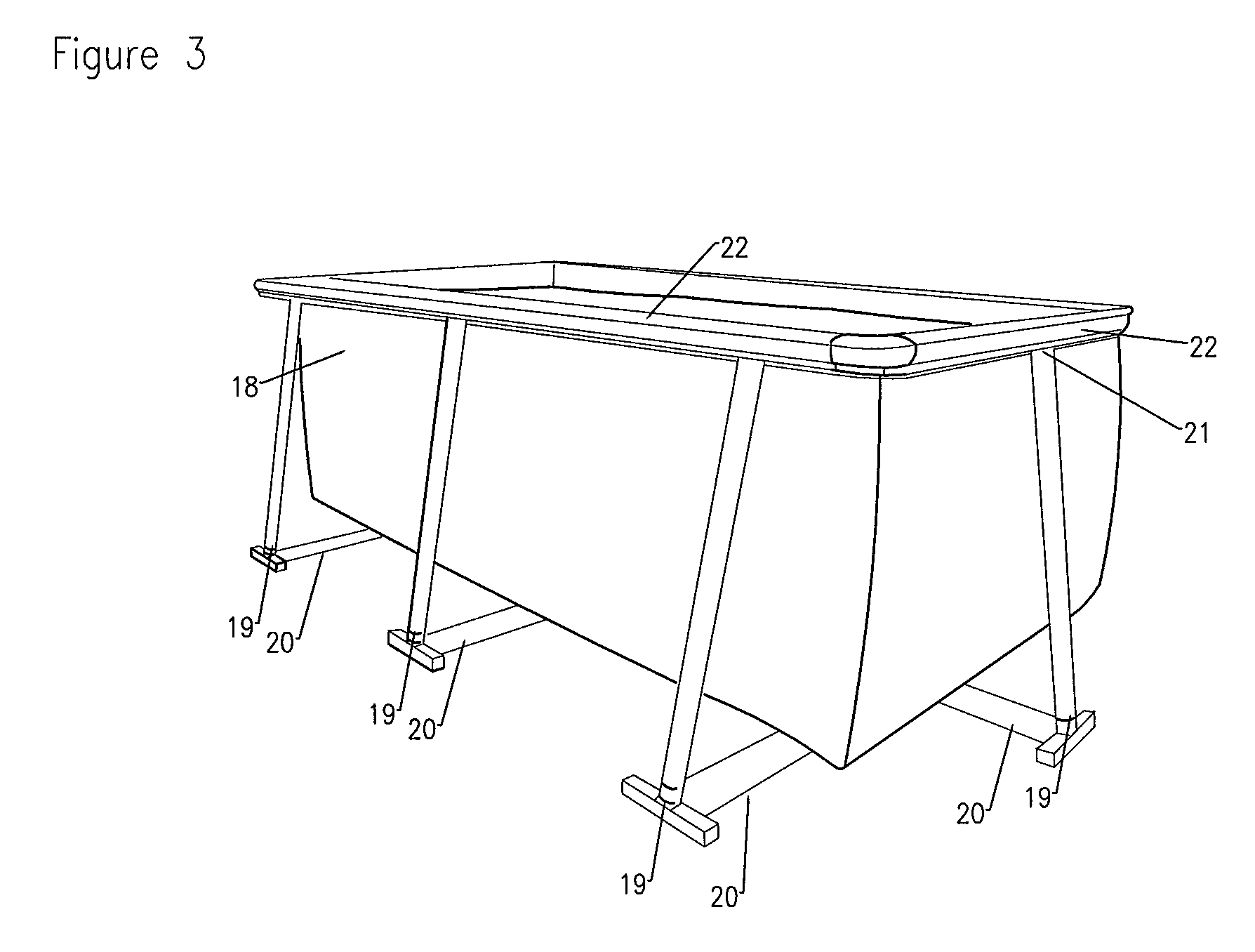

[0019]FIG. 3 shows a one piece rectangular liner 18, supported by a number of leg assemblies 19, which are tied back to the liner by braces 20. The legs fasten to a top rail assem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com