Folding Flue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

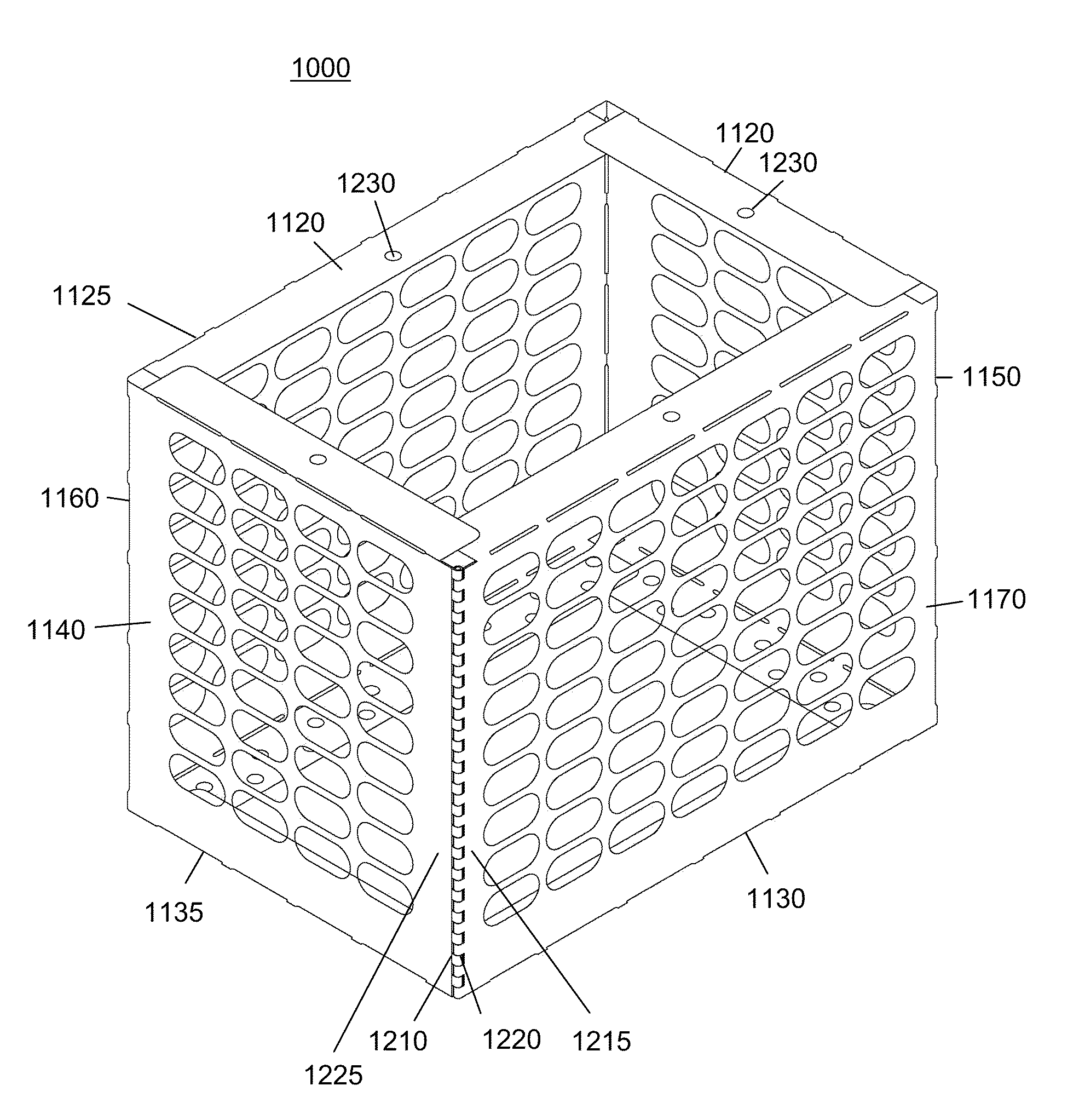

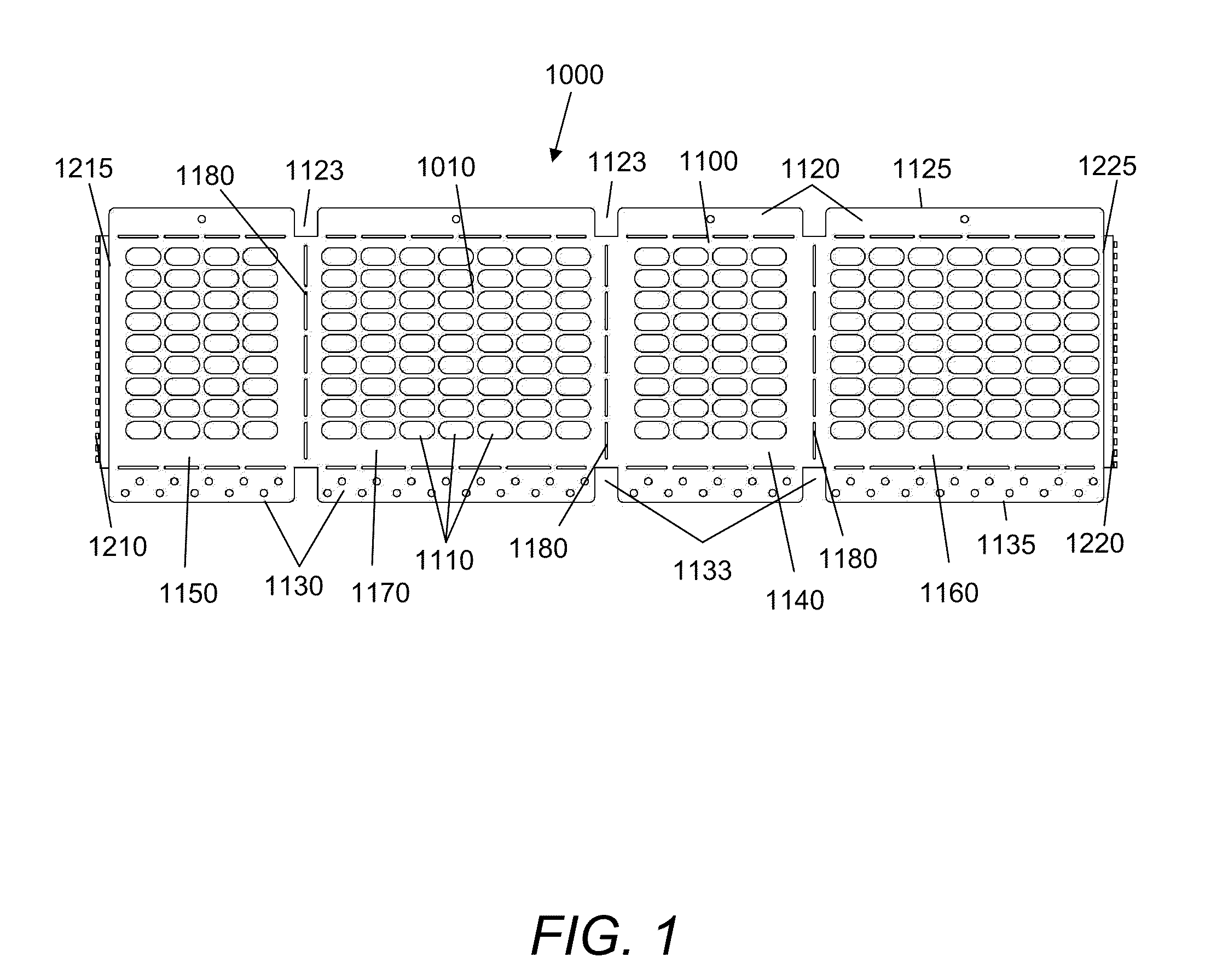

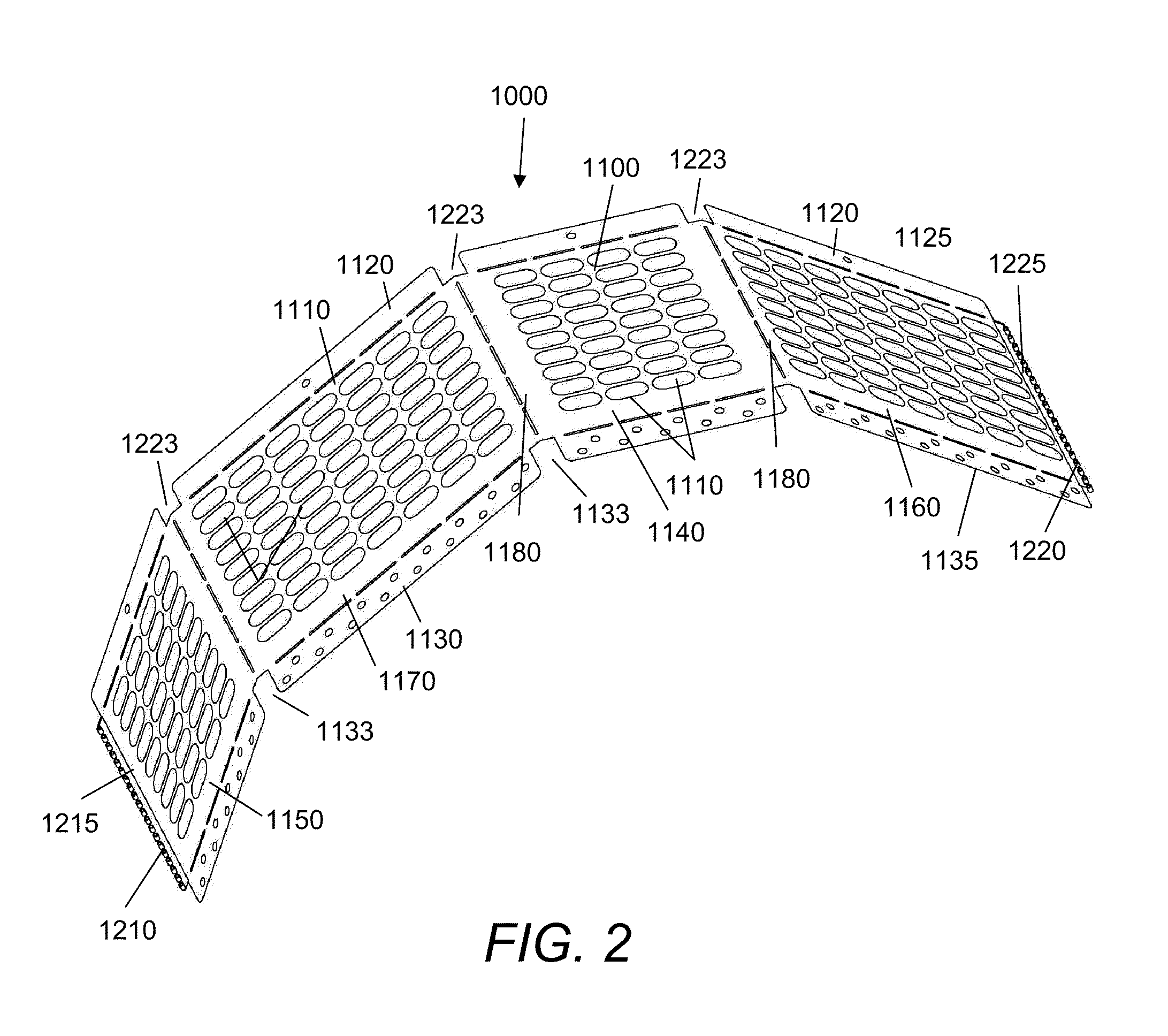

[0031]FIG. 1 is a plan view of one embodiment of a folding flue according to the present invention as it would be shipped. A body [1100] is shown in its unfolded flat view. Body [1100] has vent holes [1110] cut into it.

[0032]Body [1100] has stamped or perforated or otherwise weakened fold lines [1180]. Fold lines [1180] are a narrow area of reduced strength. These fold lines [1180] are typically constructed by running a roller blade over a metal sheet thereby producing indentations and a thinned area. Here they are created by cutting slots. When a sheet having a fold line [1180] is bent, it tends to bend at the fold line [1180] and not elsewhere on the sheet.

[0033]Body [1100] has several fold lines [1180] which separate it into end panels [1140, 1150], and side panels [1160, 1170]. Each of these panels has a top tab [1120] and a bottom tab [1130].

[0034]A first connector part [1210] is attached to one end of body [1100] and a second connector part [1220] is attached to the other end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com