Cigarette tin with internal ramp

a cigarette tin and ramp technology, applied in the field of cigarettes packaging, can solve the problems of easy spillage of contents of the tin during use of the device, complex and costly manufacturing mechanisms, and the lack of product differentiation in the marketplace of product packaging itself, so as to preserve the freshness and aroma of cigarettes, eliminate exposed sharp edges, and add rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

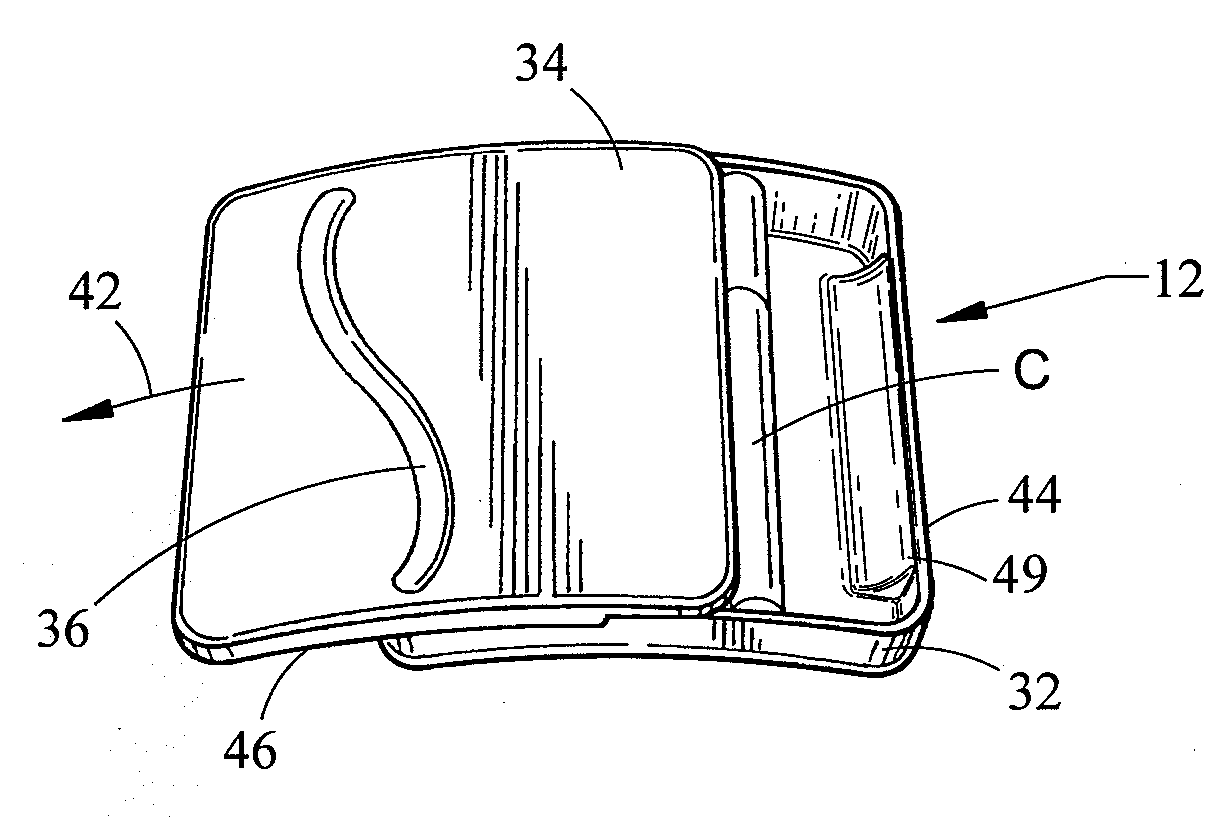

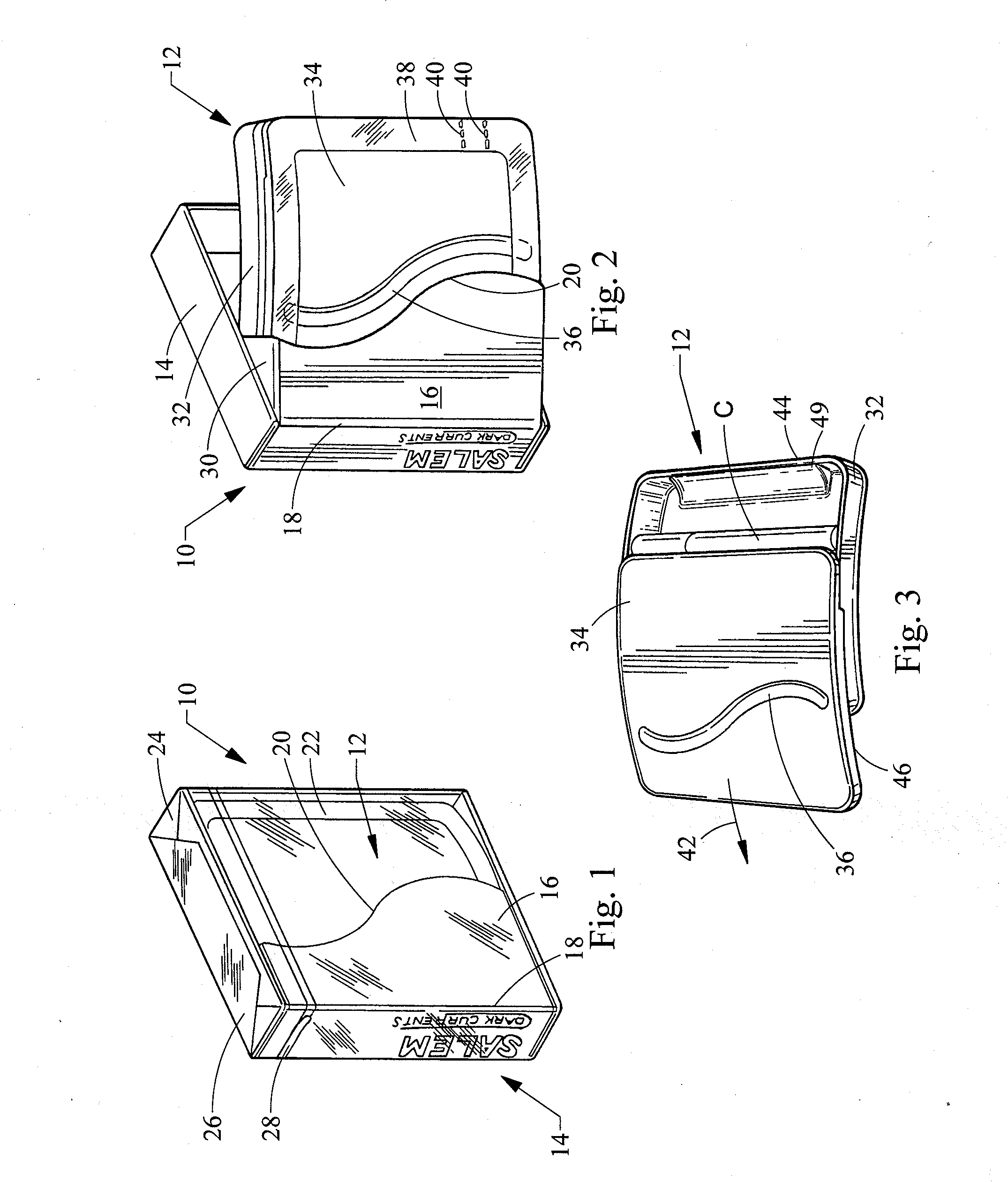

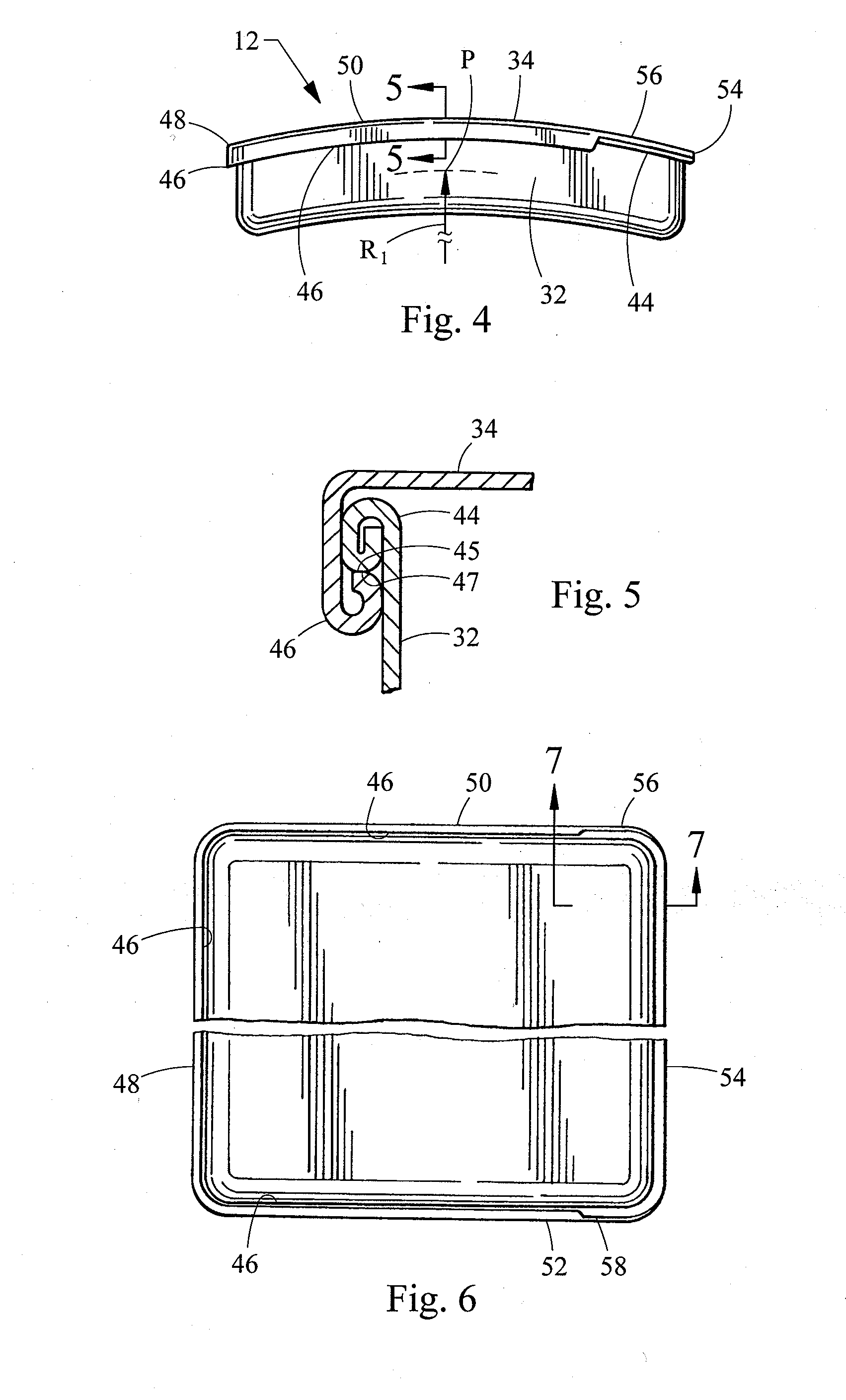

[0032]Referring now in detail to the drawings, preferred embodiments of the invention shown in FIGS. 1-14 comprise a smoking article (e.g., filter cigarette, cigarillo) package 10. In the embodiment shown in FIG. 1, package 10 has a rectangular parallelepiped shape and contains a metal cigarette box 12 described in more detail below. The package 10 includes a paperboard container 14 folded from a paperboard blank (not shown) into a parallelepiped shape. The container 14 is provided with a front panel or lid 16 hinged along folded corner 18 of the container 14. Front panel 16 only partially covers the front opening of the box so as to leave exposed a portion of the metal cigarette box 12.

[0033]The free edge 20 of the lid 16 is generally S-shaped as shown, it being understood that edge 20 may have other shapes, both linear and non-linear. For instance, the edge 20 may be a straight linear edge oriented at an angle with respect to hinged corner 18, it may have a V-shape, or it may have...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com