Polishing platen and polishing apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

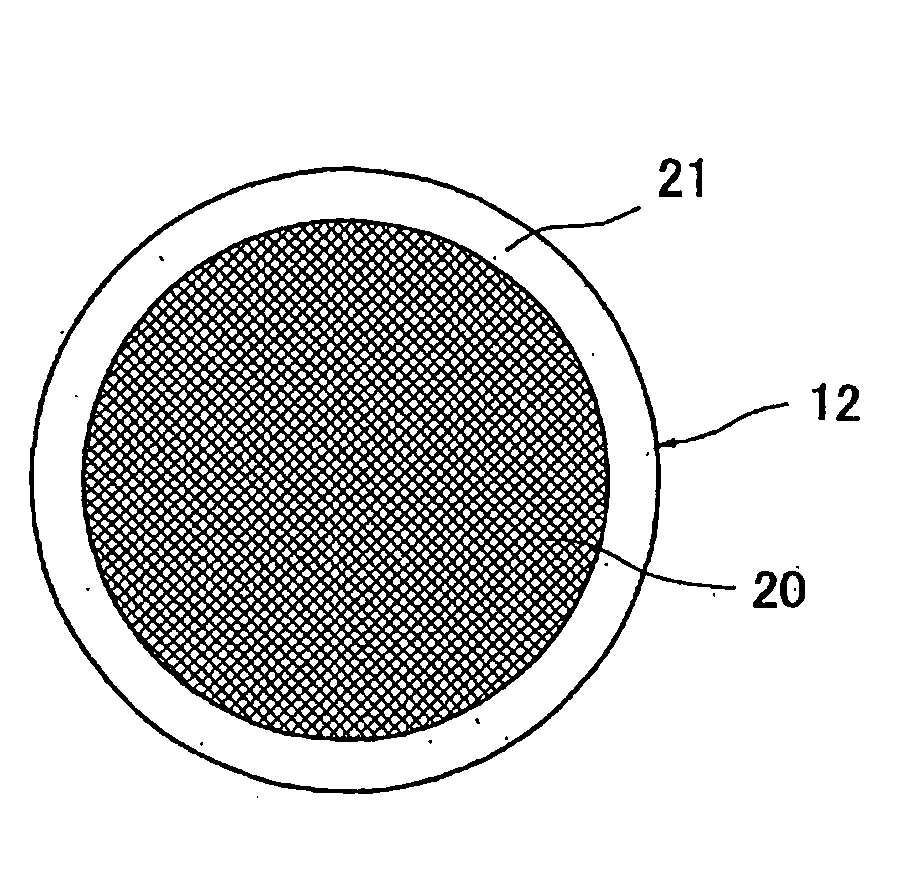

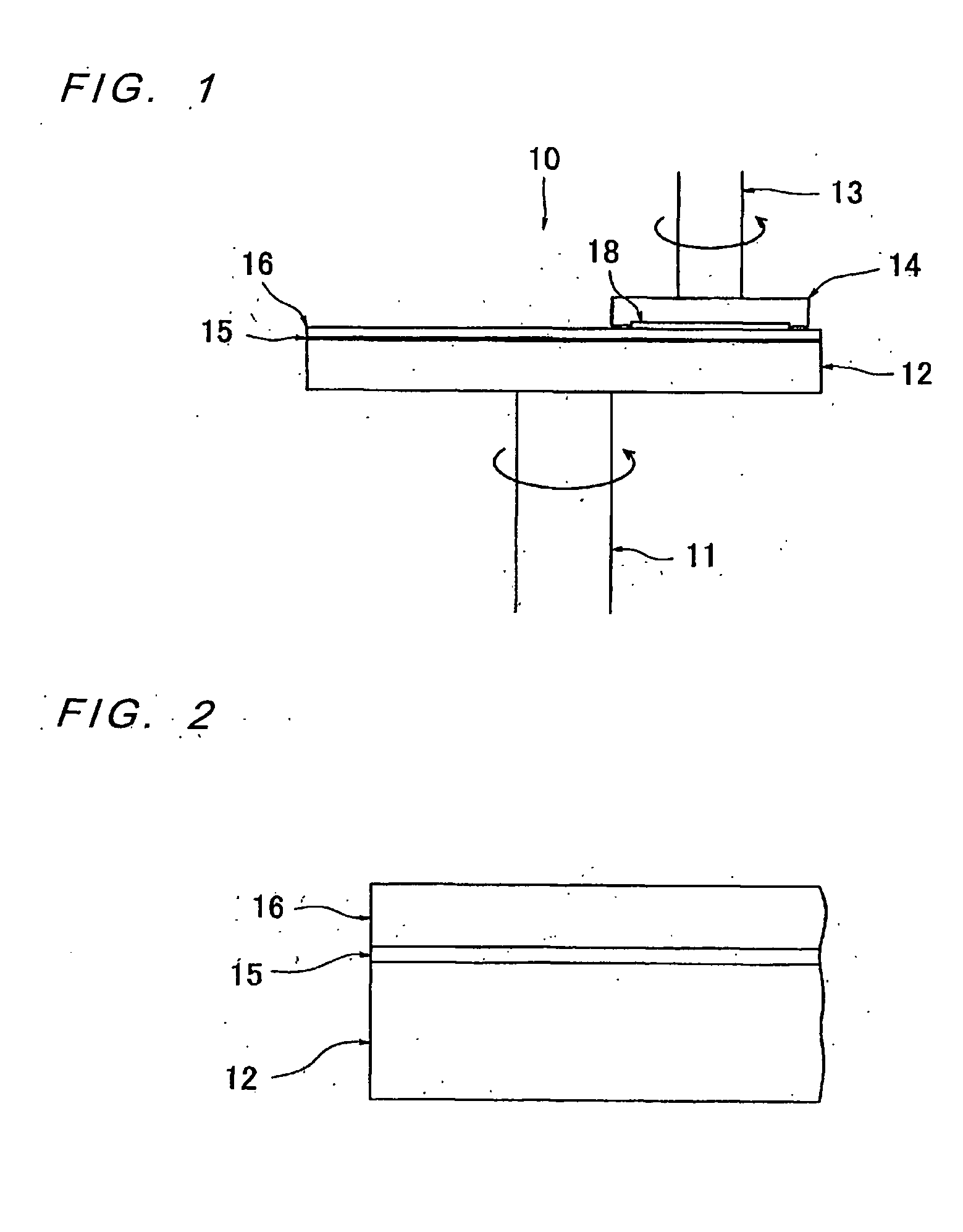

[0030]Embodiments of the present invention will be described below with reference to the drawings. FIG. 3 is a plan view showing a structural example of an upper surface of a polishing platen of a polishing apparatus according to the present invention. As shown in the drawing, an upper surface of a polishing platen 12 comprises a circular rough surface portion 20 which is a grained surface at a center thereof, and a belt-shaped mirror surface portion 21 which is a mirror-finished surface arranged around the rough surface portion 20.

[0031]A rear surface of a polishing pad 16 is attached to the upper surface of the polishing platen 12 with an adhesive (e.g., adhesive tape) 15. With this structure, the belt-shaped mirror surface portion 21 provides a strong adhesive area, but the circular rough surface portion 20 provides a weak adhesive area. Thus, when an operation of removing the polishing pad 16 is started from its edge portion, i.e., a peripheral portion of the mirror surface port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com