Substrate processing apparatus and substrate processing method for successively processing a plurality of substrates

a processing apparatus and substrate technology, applied in the direction of gripping heads, thin material processing, article separation, etc., can solve the problems of increasing the number of transporting processes using the transport robot, increasing the number of transporting processes, and robots not being able to perform the transporting process. , to achieve the effect of reducing the standby time of the transport robot and minimizing the number of reverse passing parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034]Hereinafter, detailed discussion will be made on the preferred embodiment of the present invention with reference to figures.

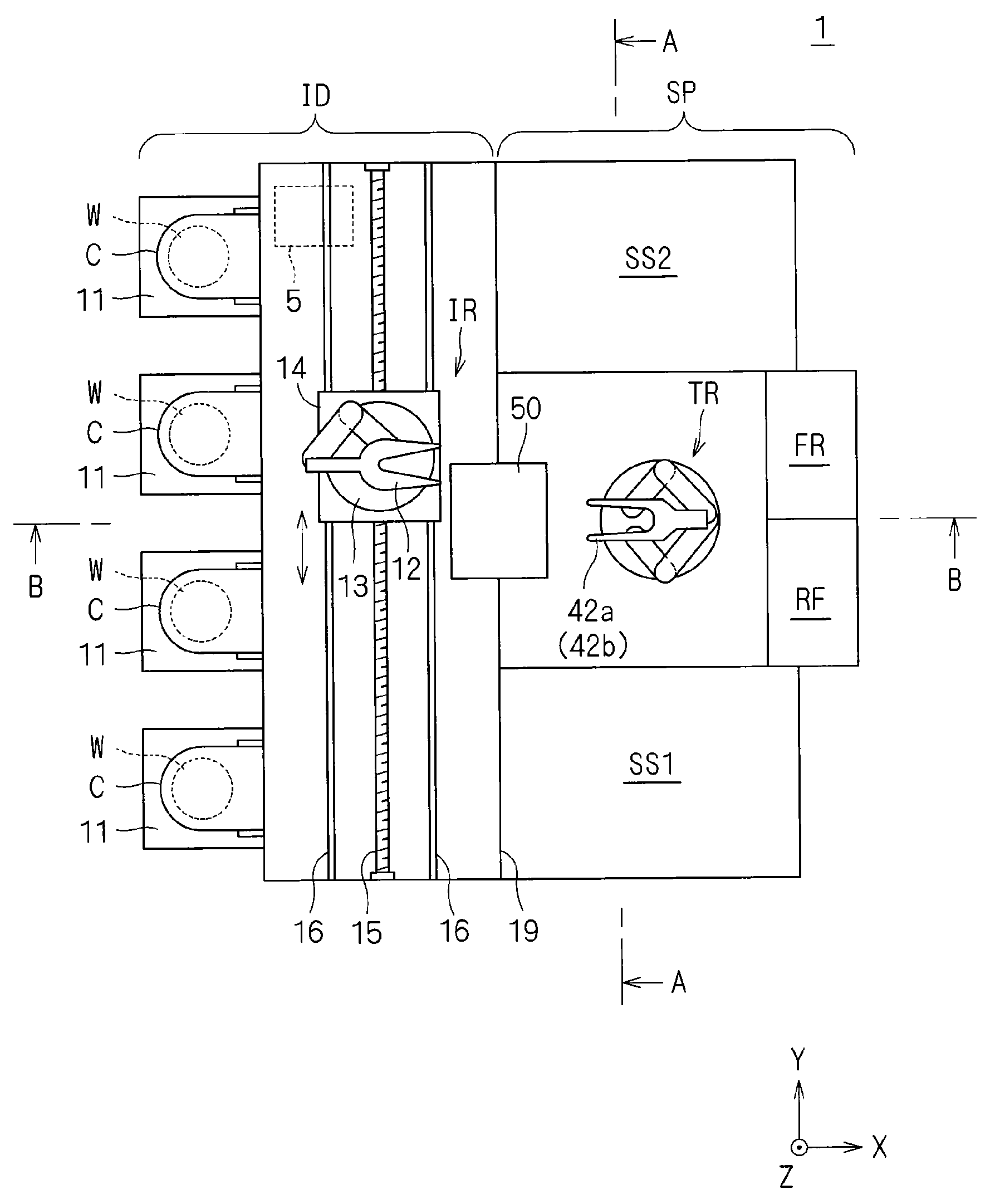

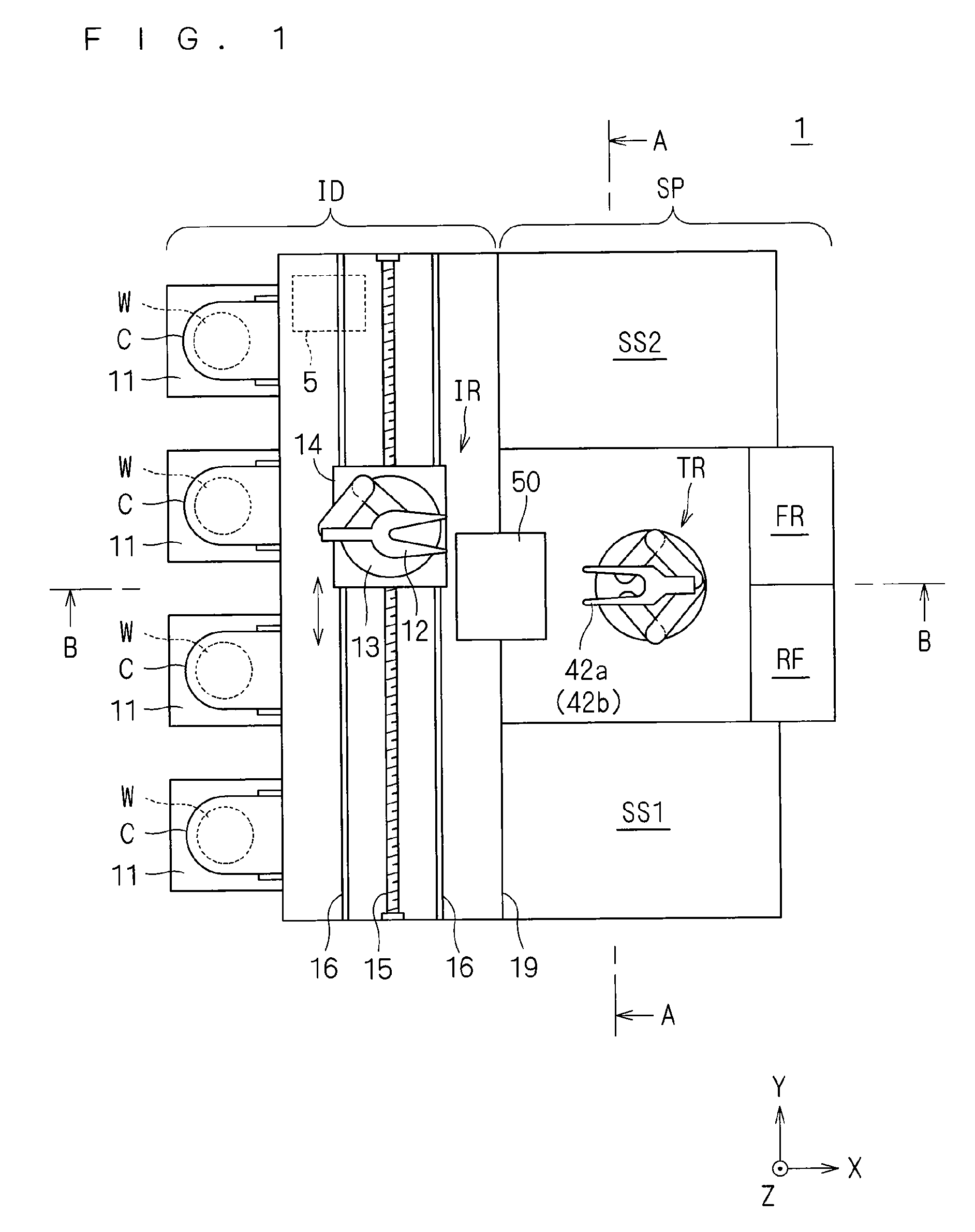

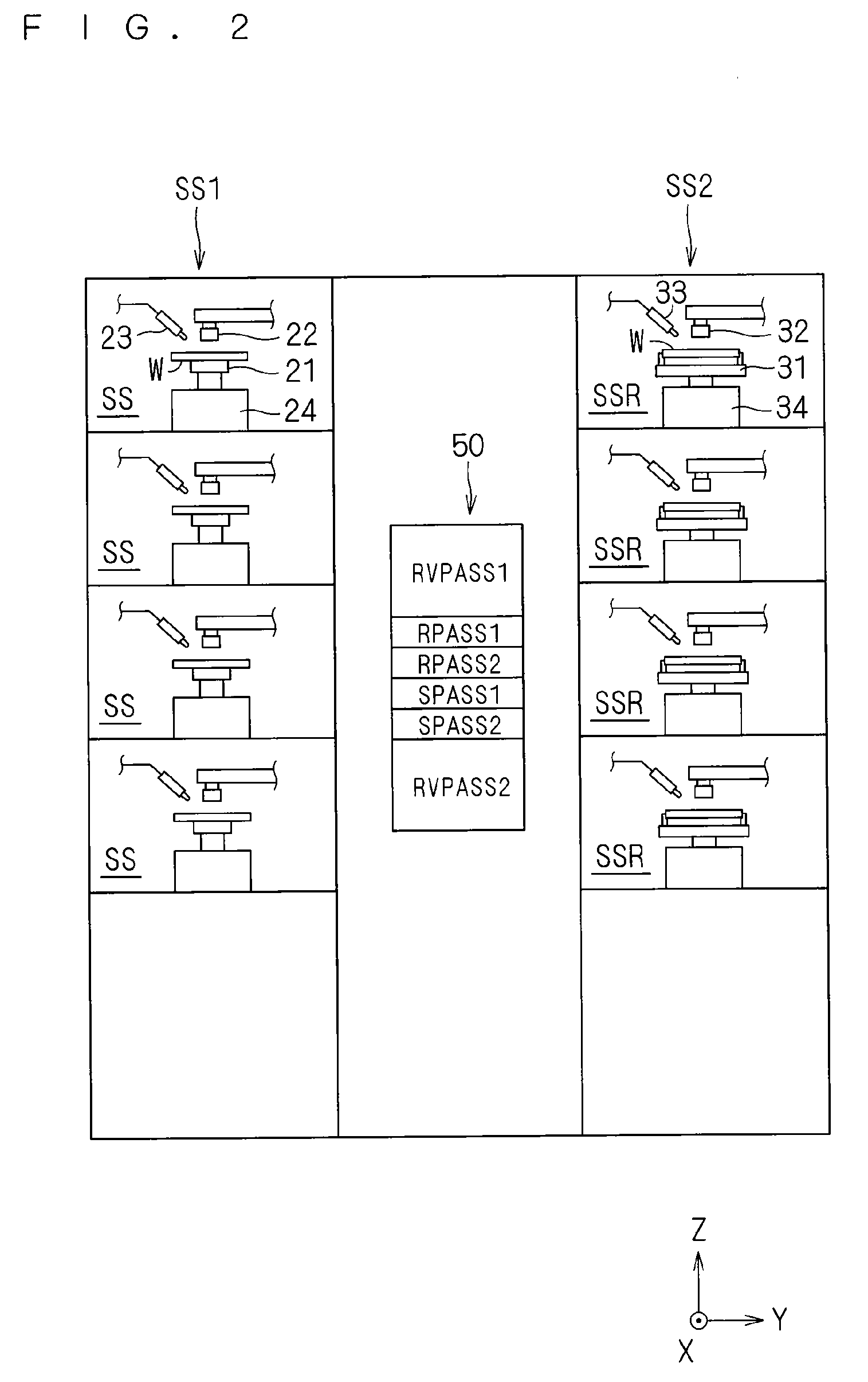

[0035]FIG. 1 is a plan view showing a substrate processing apparatus 1 in accordance with the present invention. FIG. 2 is a view taken along the line A-A of FIG. 1 and FIG. 3 is a view taken along the line B-B of FIG. 1. In FIGS. 1 to 3, an XYZ rectangular coordinate system in which the Z-axis direction is defined as the vertical direction and the XY plane is defined as the horizontal plane is additionally shown for the purpose of clarifying the directional relationship therebetween. The substrate processing apparatus 1 is a cleaning device for performing a scrub cleaning process successively on a plurality of substrates W such as semiconductor wafers or the like, in which two cells (processing sections), i.e., an indexer cell ID and a cleaning cell SP, are arranged in parallel. The substrate processing apparatus 1 further comprises a control part 5 for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com