Cutting bit useful for impingement of earth strata

a cutting bit and earth strata technology, applied in the direction of cutting machines, earth drilling and mining, slitting machines, etc., can solve the problems of increasing the resistance of the cutting bit to the impingement, and reducing the service life of the cutting bi

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

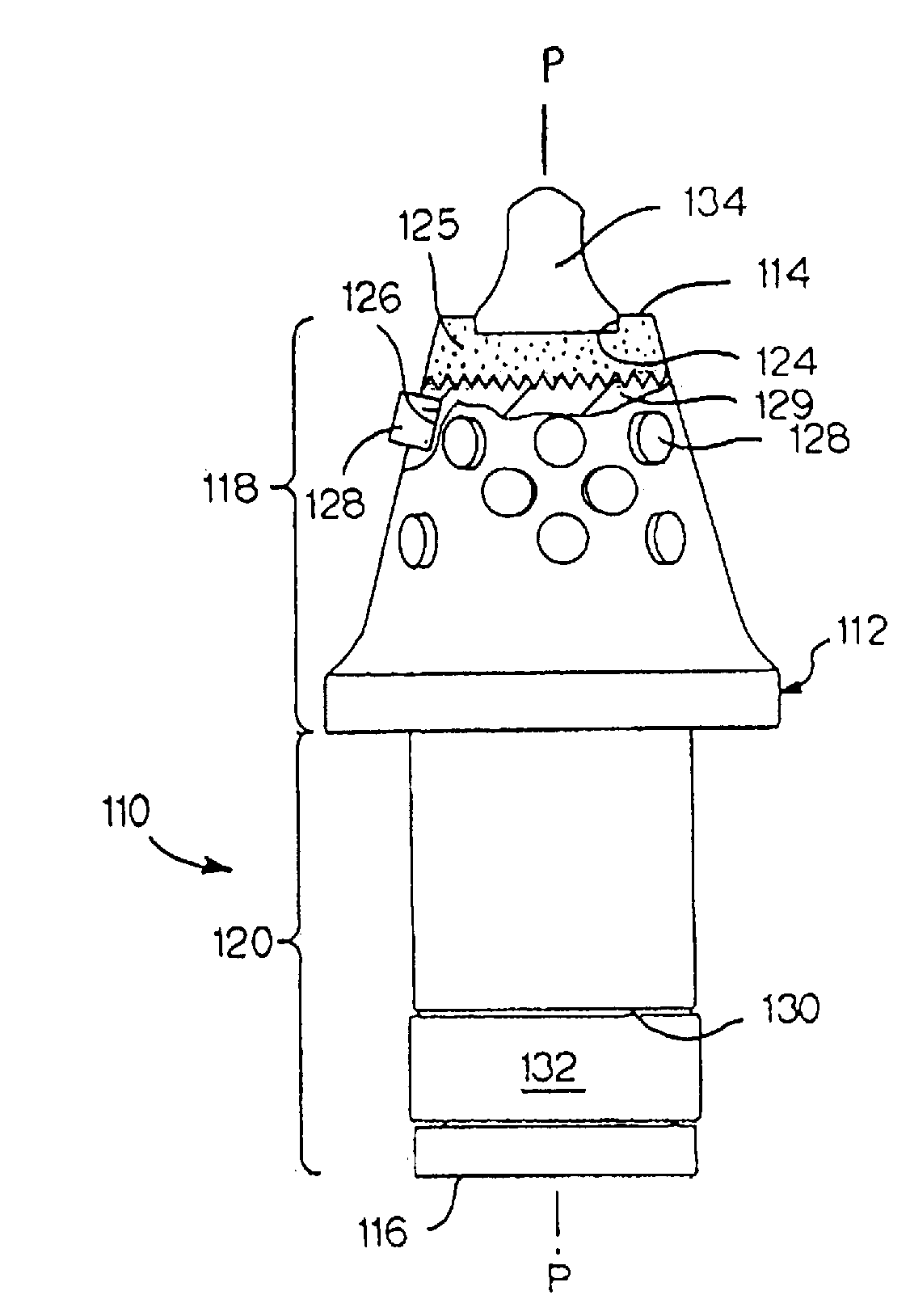

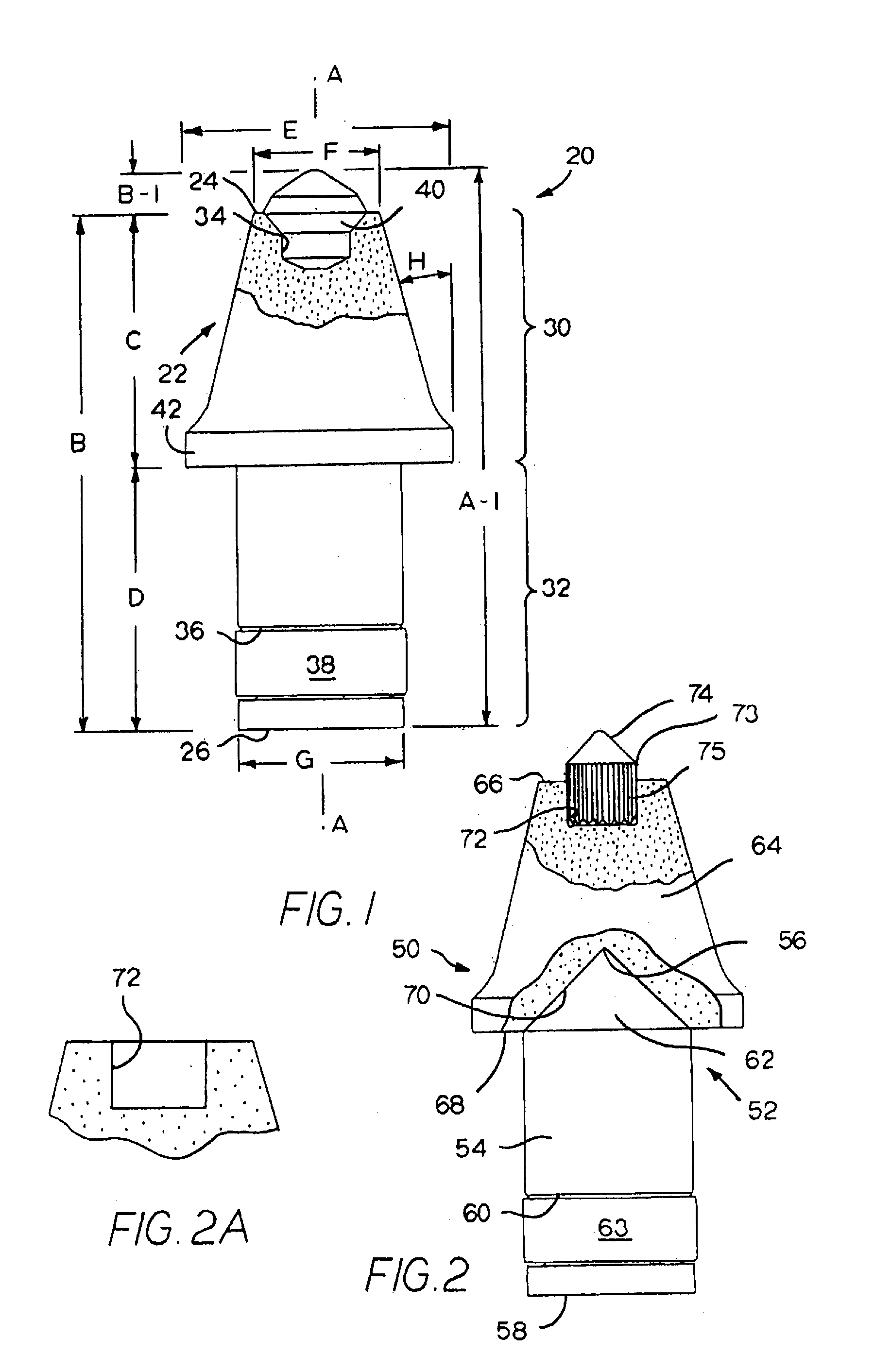

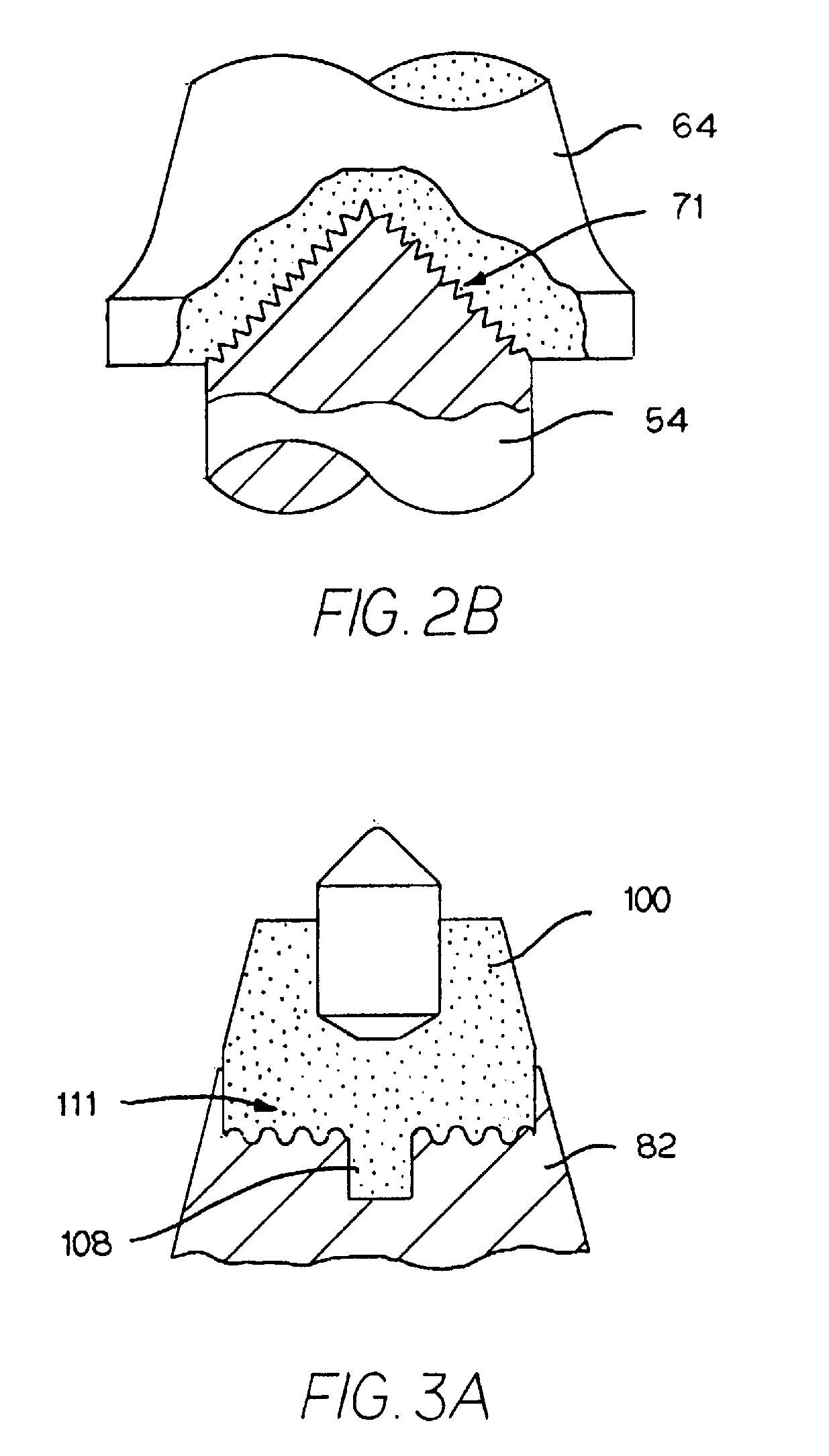

[0034]Referring to the drawings, FIG. 1 illustrates a first specific embodiment of a rotatable cutting bit of the invention for impinging the earth strata, wherein the cutting bit is generally designated as 20. Here, earth strata refers to a wide variety of substrate-type materials upon which the cutting bit impinges thereby breaking earth strata into pieces. The specific earth strata can vary depending upon the particular application. For example, in a mining application, earth strata may comprise the mined material such as coal or the like. In a trenching application, earth strata may comprise dirt and in some cases concrete. In a road planing application, earth strata may comprise the roadway materials such as, for example, asphaltic roadway material and concrete roadway material. In addition, there is the contemplation that the rotatable cutting bits of the invention are useful in foundation drilling, rock cutting, and drilling for oil and / or gas deposits. Further, although the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Wear resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com