Anti-tracking feature for rock bits

a technology of anti-tracking and rock bits, which is applied in the field of drill bits, can solve the problems of reducing the unit load of the cutting element, affecting the cutting effect, and affecting the cutting effect, and achieves the effect of reducing the tracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

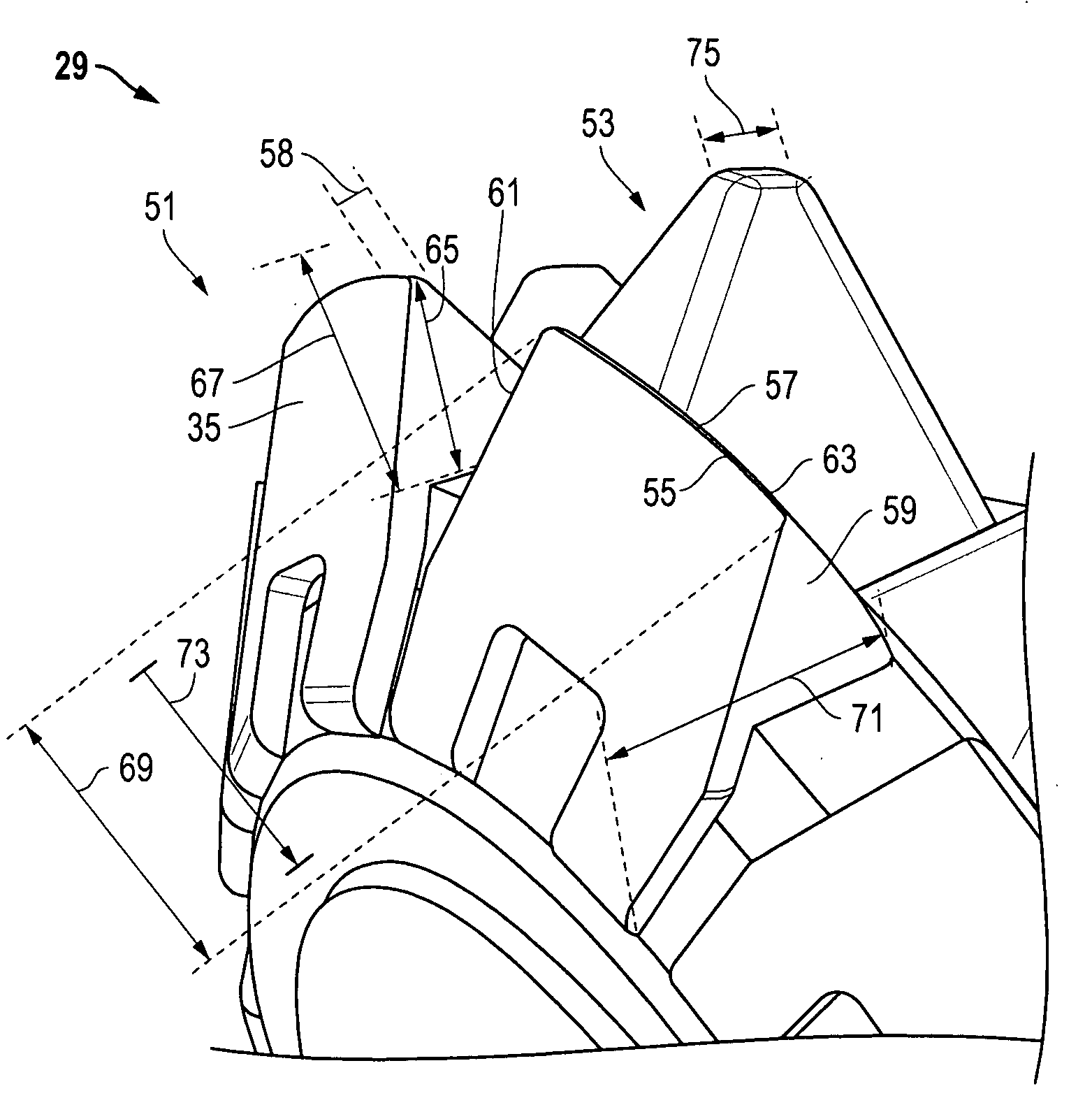

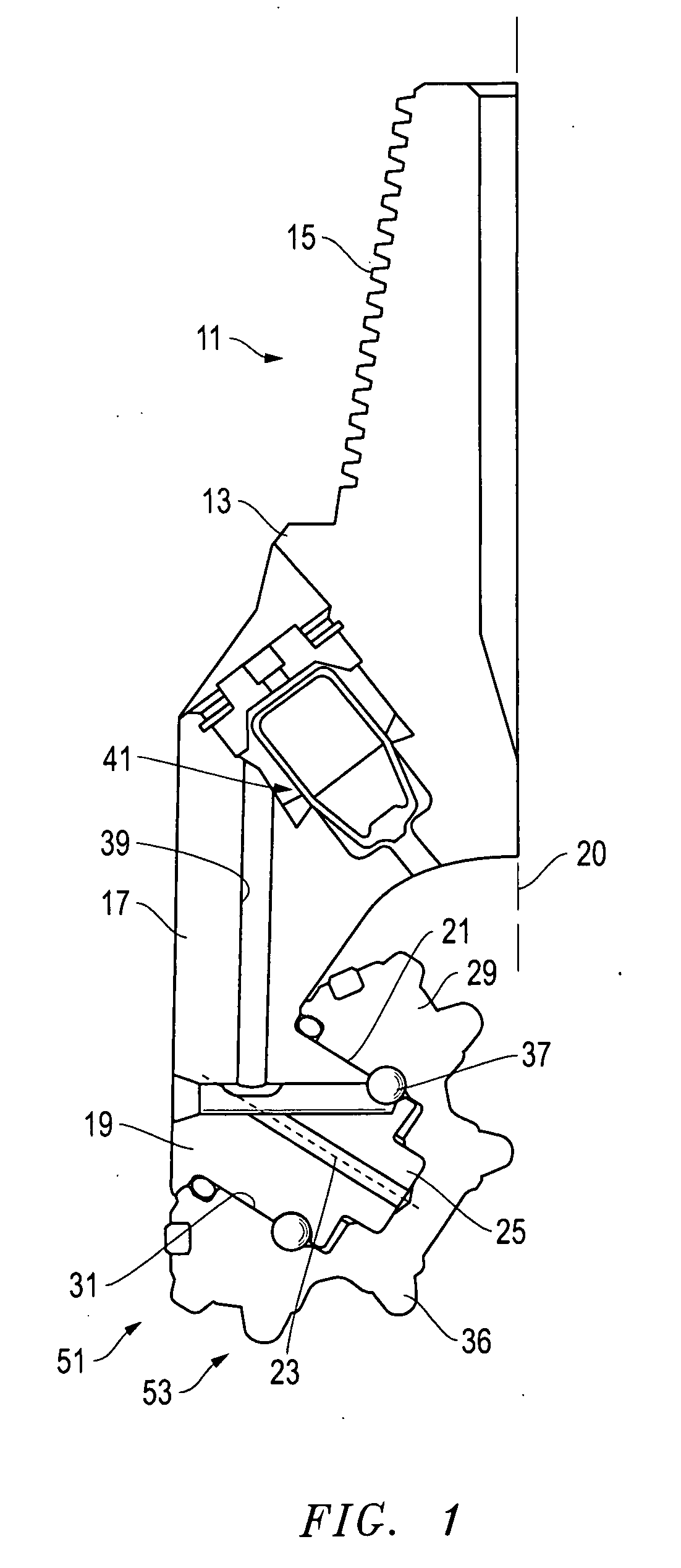

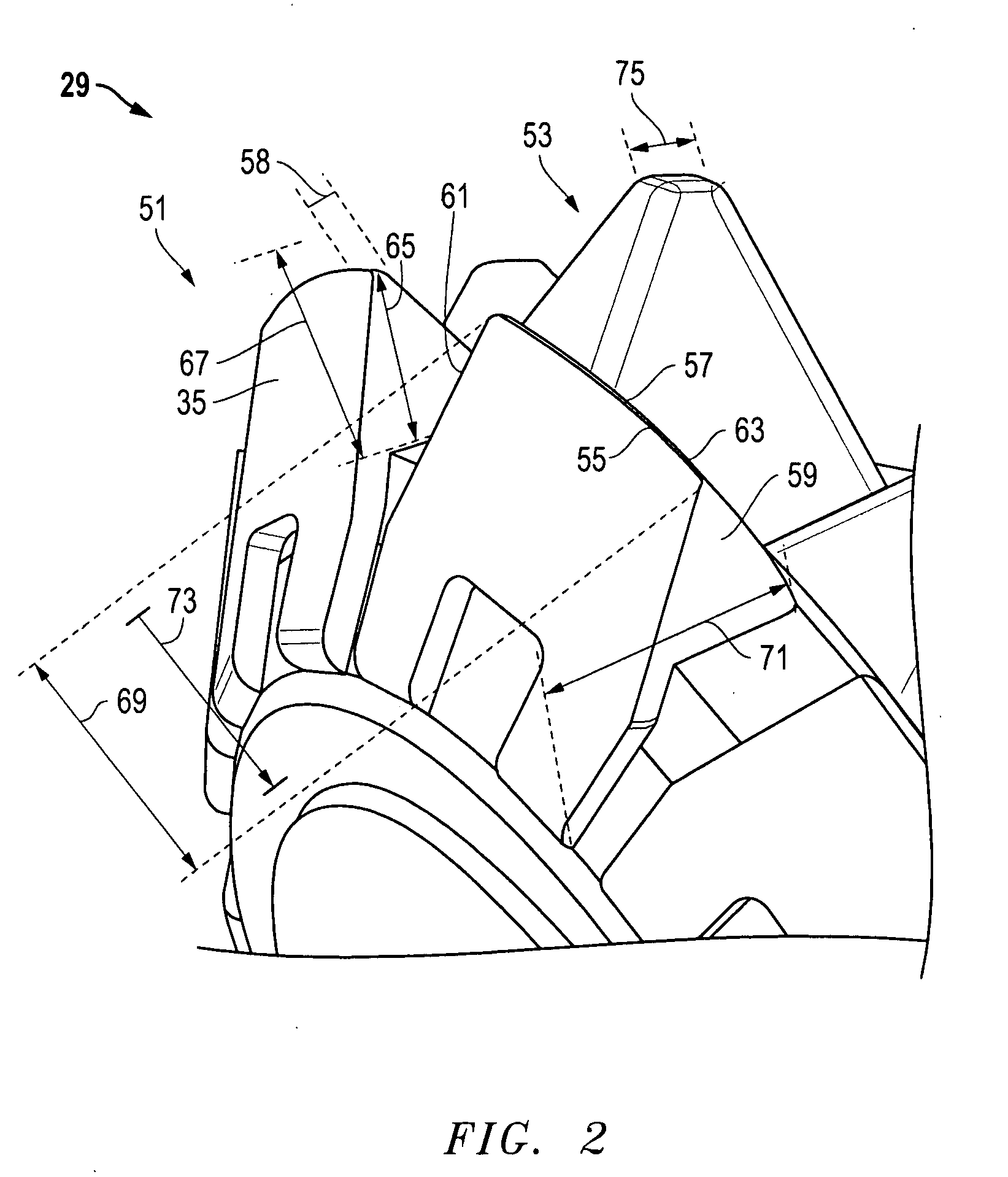

[0030]Referring to FIGS. 1-15, embodiments of an improved system, method, and apparatus for reducing the harmful effects of tracking with drill bits are disclosed. One embodiment of a bit 11 (FIG. 1) has a body 13 with a threaded shank 15 on its upper end for connection to a drill string (not shown). Body 13 typically has three bit legs 17 (only one shown), and each leg 17 has a depending bearing pin 19. Each bearing pin 19 inclines downward and inward toward an axis 20 of rotation of body 13. Each bearing pin 19 has a cylindrical surface 21 that is concentric with a bearing pin axis 23. A roller cone 29 is mounted to each pin 19 and has an axial cavity with a cylindrical portion 31 that fits around bearing surface 21 of pin 19. Roller cone 29 rotates on pin 19 about its roller cone axis, which coincides with bearing pin axis 23.

[0031]Each roller cone 29 has a plurality of cutting elements 36 (FIG. 1) on its exterior. Cutting elements 35 may be formed as steel teeth milled into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com