Icing resistant reduced noise air motor exhaust

a technology of motor exhaust and icing resistance, which is applied in the direction of machines/engines, liquid fuel engines, positive displacement liquid engines, etc., can solve the problems of increasing the duration of noise, reducing noise levels, and reducing peak levels, so as to reduce noise, reduce noise, and minimize downstream exhaust pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

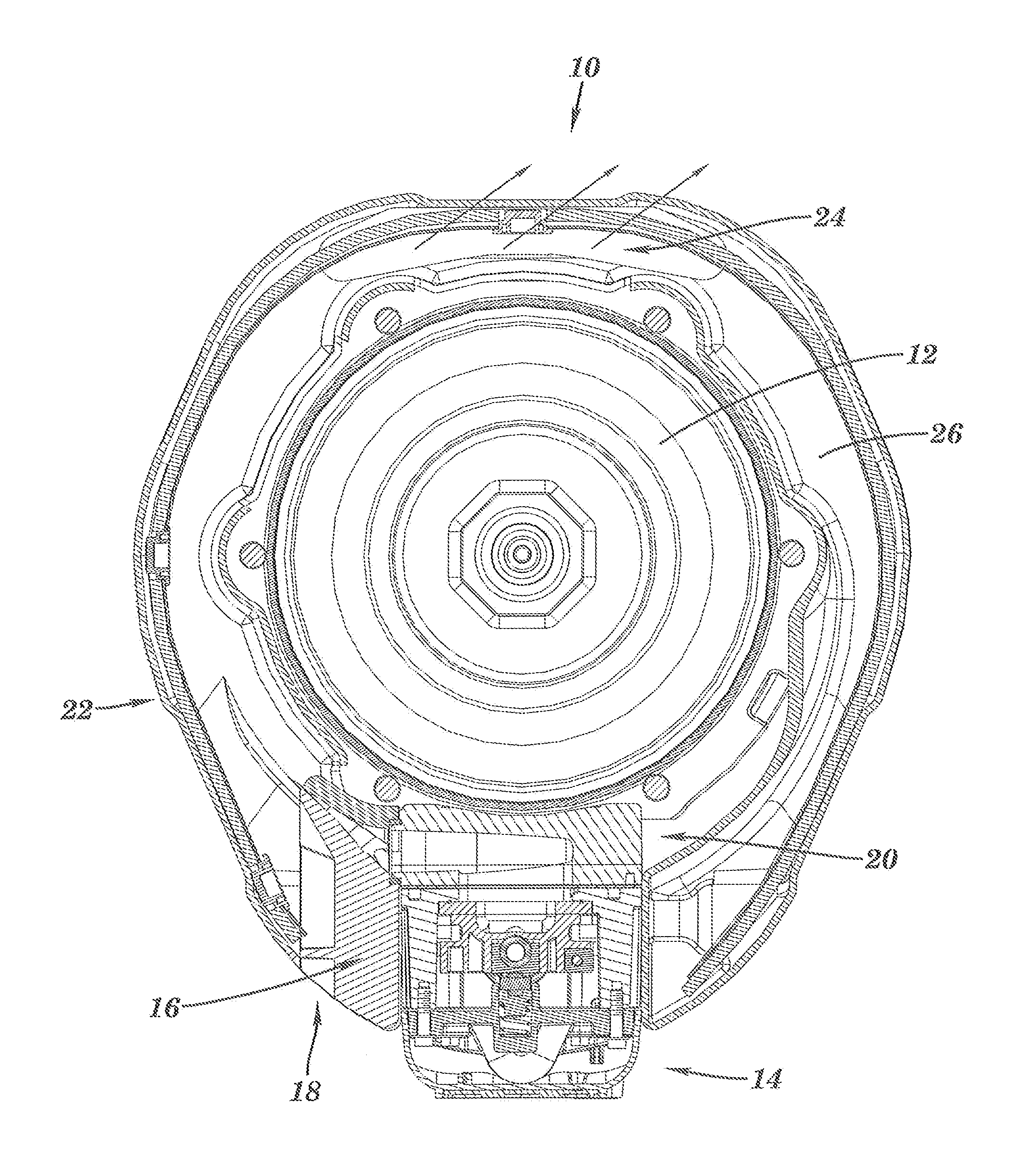

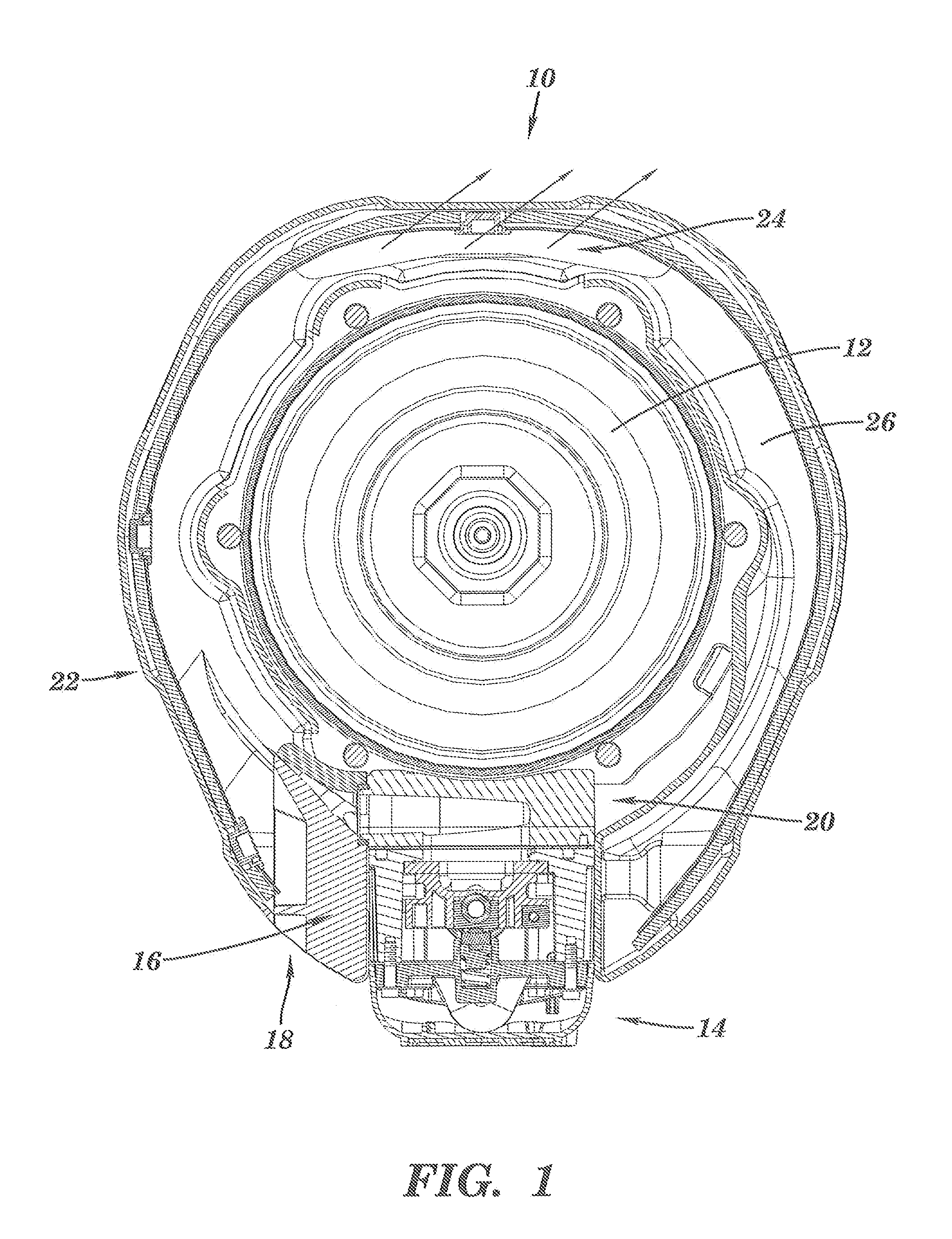

[0009]The air motor 10 of the instant invention has a piston 12 and an air valve 14. The induction exhaust has an exhaust manifold 16 and a muffler 22. In the instant invention, warm ambient air is drawn into the muffler 22. Heat from this external source is conducted through the finned manifold 16 to melt ice that can form inside the manifold 16 during the exhaust cycle.

[0010]The exhaust manifold 16 directs the exhaust air stream into the muffler 22 such that it creates a thin high velocity air stream creating a low pressure region on both sides of the stream due to the Bernoulli effect. This low pressure region creates a pressure differential which draws the warm external air into the exhaust system. The more external air that is drawn in, the more that icing will be reduced. This requires minimizing downstream exhaust pressure.

[0011]Minimizing downstream exhaust pressure, however, can lead to higher noise levels. In order to reduce noise, a reverberation chamber 26 is added after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com