Apparatus for defeating high energy projectiles

a technology of high-energy projectiles and armor, applied in the field of armor systems, can solve the problems of heavy armor thickness, high cost, and obvious detrimental effects of occurrence on the system and personnel of the vehicle, and achieve the effects of reducing the number of vehicles using conventional armor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

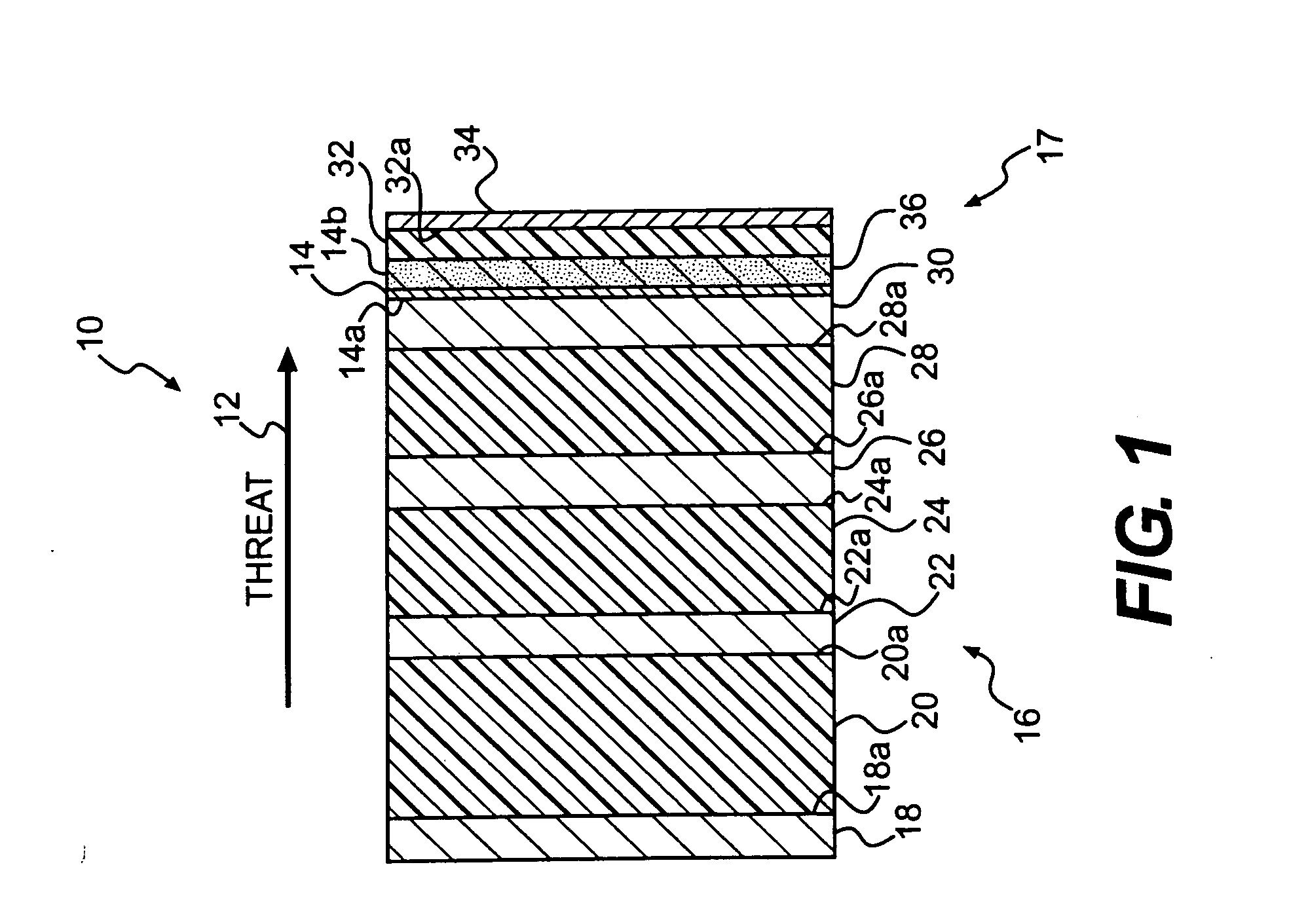

[0030]FIG. 1 presents the invention, namely an armor system generally designated by the numeral 10 for protecting a vehicle from high energy projectiles. In the following discussion, the projectile has an expected trajectory relative to the vehicle, which trajectory is designated by the numeral 12 in the figures. Trajectory 12 establishes a direction for understanding certain terms used in the following discussion, such as “leading,”“rear” or “behind,”“front,” etc., namely the direction that the components of armor system 10 would successively confront the projectile as it approached the vehicle hull, designated generally by the numeral 14. Moreover, the terms are “exterior” and “interior” as used in conjunction with the vehicle hull 14 are given their usual meanings.

[0031]Specifically, armor system 10 in the FIG. 1 embodiment includes exterior armor subsystem 16 and interior armor subsystem 17. Exterior armor subsystem 16 more particularly includes a leading sheet-like layer 18 of ...

embodiment 10

[0036]An example of a particular armor system constructed in accordance with embodiment 10 depicted in FIG. 1 may have each of leading aluminum layer 18 and the first “intermediate” (i.e., positioned between the leading layer and the hull) aluminum layer 22 to be about 1¼ inch thick sheets, while each of the second and third intermediate aluminum layers 26 and 30 be about 1½ inch sheets. The first intermediate low density polypropylene composite layer 20 may be about 4½ inches thick, and the second and third intermediate low density polypropylene layers 24 and 28 be about 1½ inches thick. Also, foam layer / space 36 of interior armor subsystem 17 may be about ¾ inch thick; low density polypropylene composite layer 32 about ¾ inch thick; and Kevlar® / E-Glass hybrid layer 34 about ½ inch thick.

[0037]It is contemplated that the exterior armor subsystem 16 as depicted in the embodiment of FIG. 1 can be used without the particular interior armor subsystem 17 shown, or any interior armor mat...

second embodiment

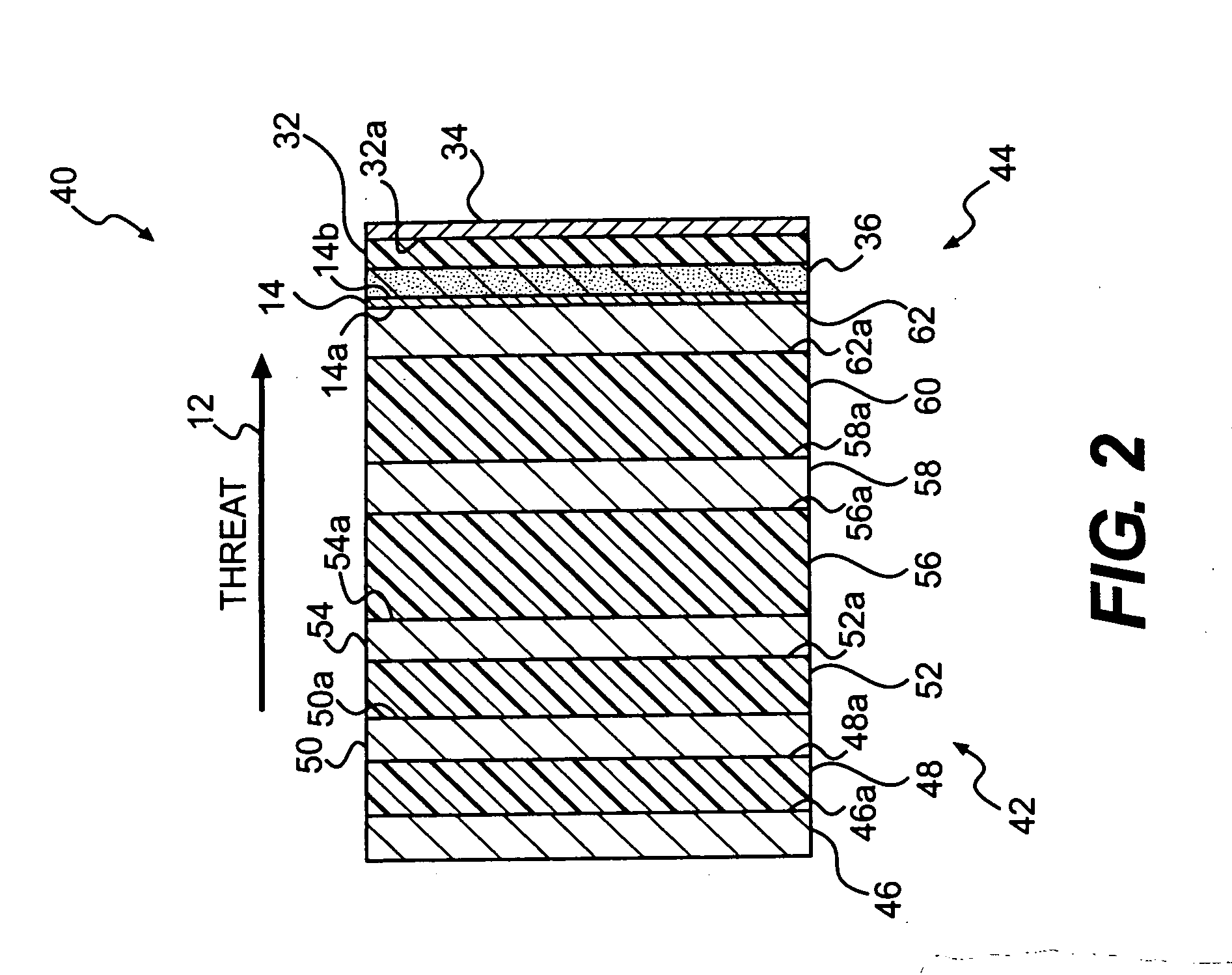

[0039]FIG. 2 depicts the armor system of the present invention, namely armor subsystem 40, which includes exterior subsystem 42 and which also may include an interior armor system 44. Interior armor system 44 in the FIG. 2 embodiment is substantially the same as interior armor subsystem 17 depicted in FIG. 1 embodiment and will therefore not be discussed further.

[0040]As in the exterior armor subsystem 16 in the FIG. 1 embodiment, the exterior subsystem 42 in the embodiment shown in FIG. 2 includes a leading layer 46 of high strength aluminum followed by alternating layers of a low density polypropylene composite and a high strength aluminum. In particular, exterior subsystem 42 includes leading high strength aluminum layer 46; a first intermediate layer 48 of low density polypropylene composite abutting rear surface 46a of leading aluminum layer 46; a first intermediate layer 50 of a high strength aluminum abutting rear surface 48a of low density polypropylene composite layer 48; s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com