Optical chiral fiber isolator and method of fabrication thereof

a technology of optical chiral fiber and isolator, which is applied in the field of optical isolators, can solve the problems of inconvenient manufacturing, low production efficiency, and high cost of conventional optical isolators, and achieves the effect of convenient and relatively inexpensive manufacturing, installation, use and maintenan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

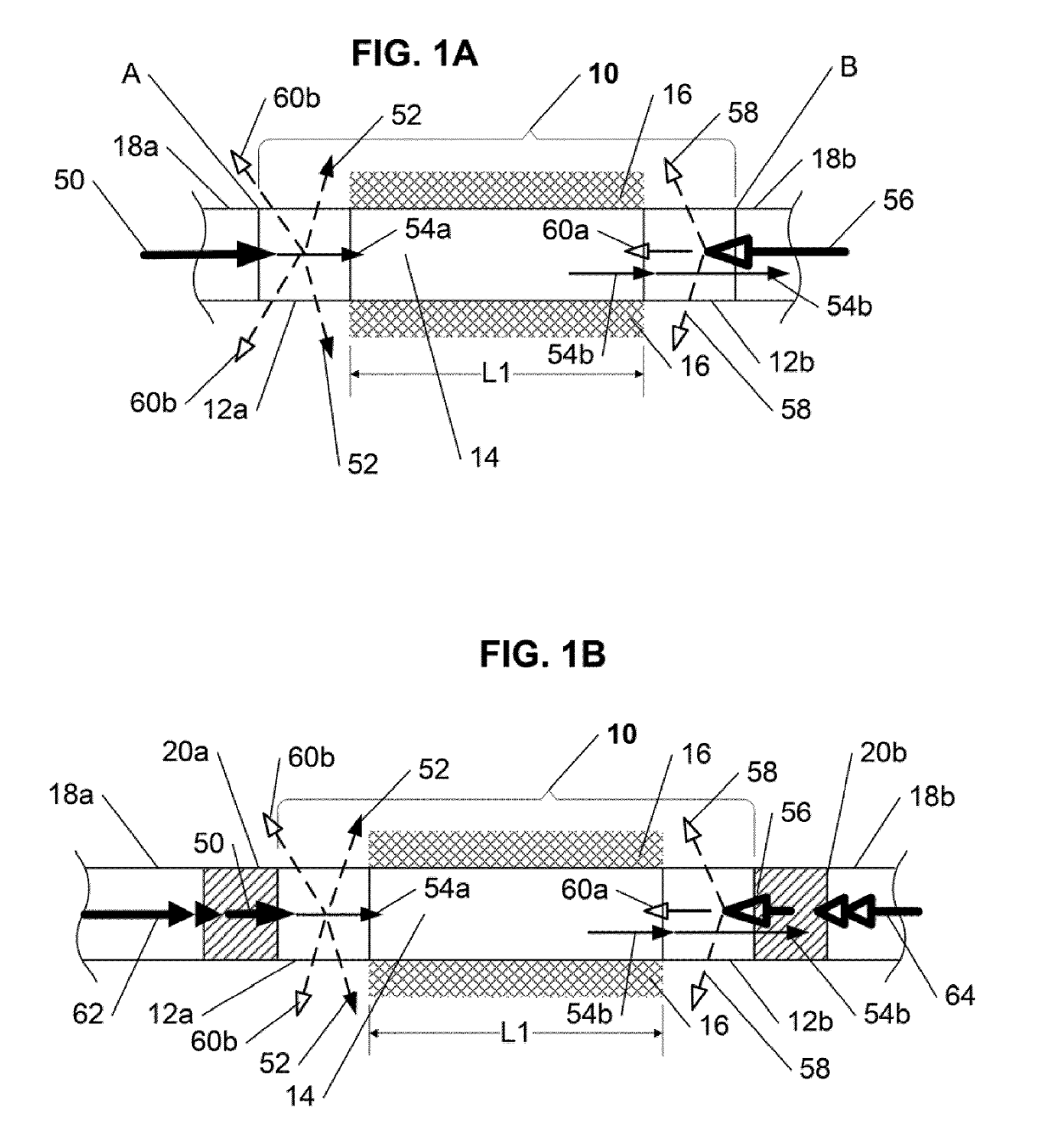

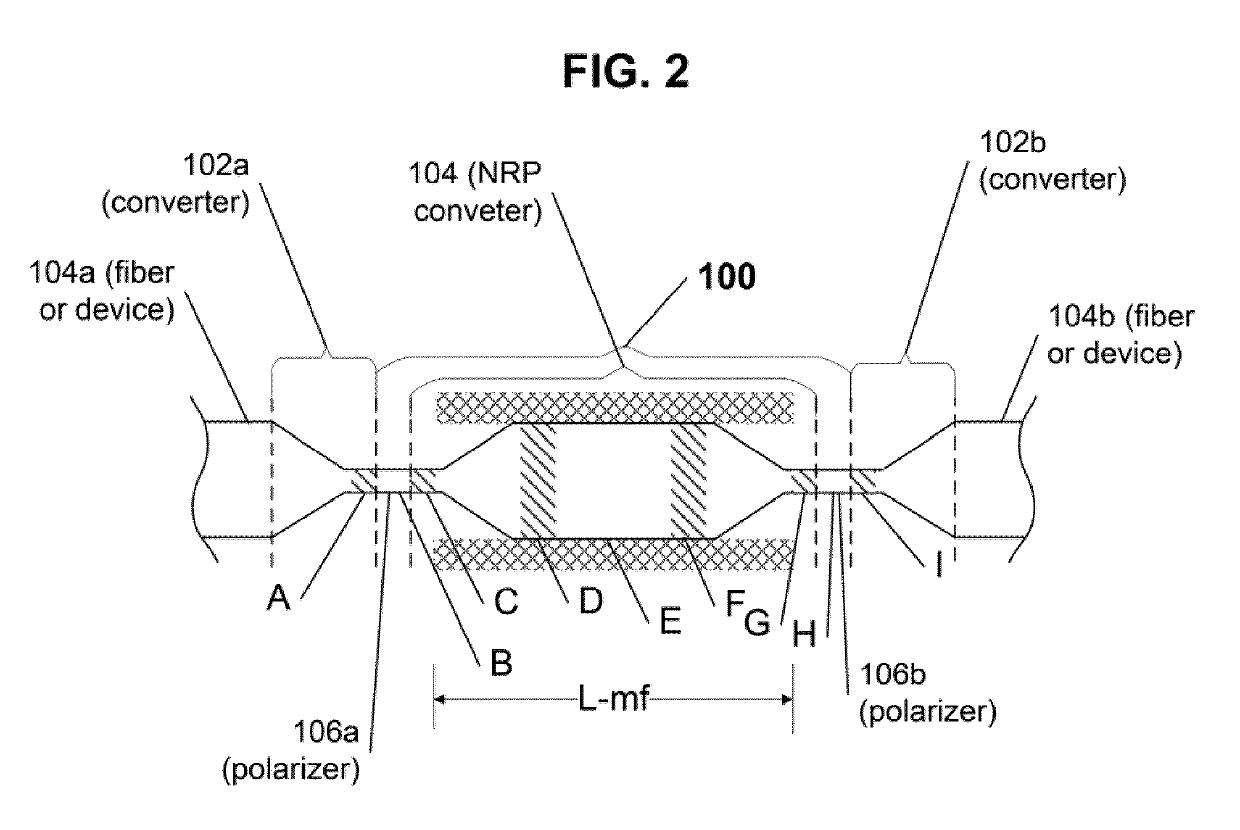

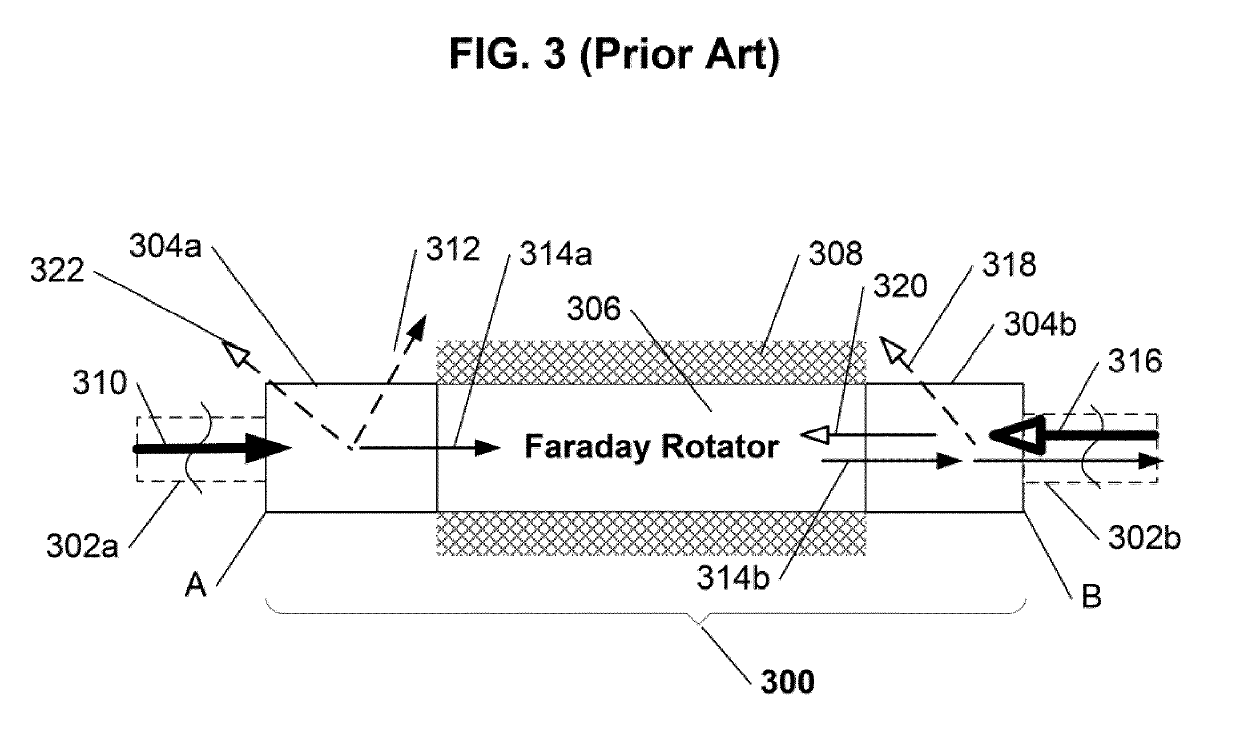

[0026]The present invention is directed to a optical in-fiber chiral fiber isolator capable of transmitting a signal (e.g., light) of a predetermined desired optical polarization in a forward direction therethrough, while rejecting all signals traveling in a backward direction therethrough.

[0027]In summary, in its first exemplary embodiment, the optical chiral fiber isolator includes a chiral magneto-optical fiber having a helical pitch profile, a birefringence profile, and an effective Verdet constant profile, at least a portion of which is exposed to a magnetic field of a predetermined magnetic field profile (generated by a proximal magnetic field source), where the magnetic field profile, the chiral pitch profile, the birefringence profile, and the effective Verdet constant profile are selected and configured such that the inventive isolator is capable of transmitting a signal of a predetermined optical polarization in a direction from its input end toward its output end, and to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com