Container lid having multiple utilities

a technology of container lids and utilities, applied in the field of container lids, can solve the problems and achieve the effect of prolonging the life of the final cleaning apparatus and maintaining the original consistency of the material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

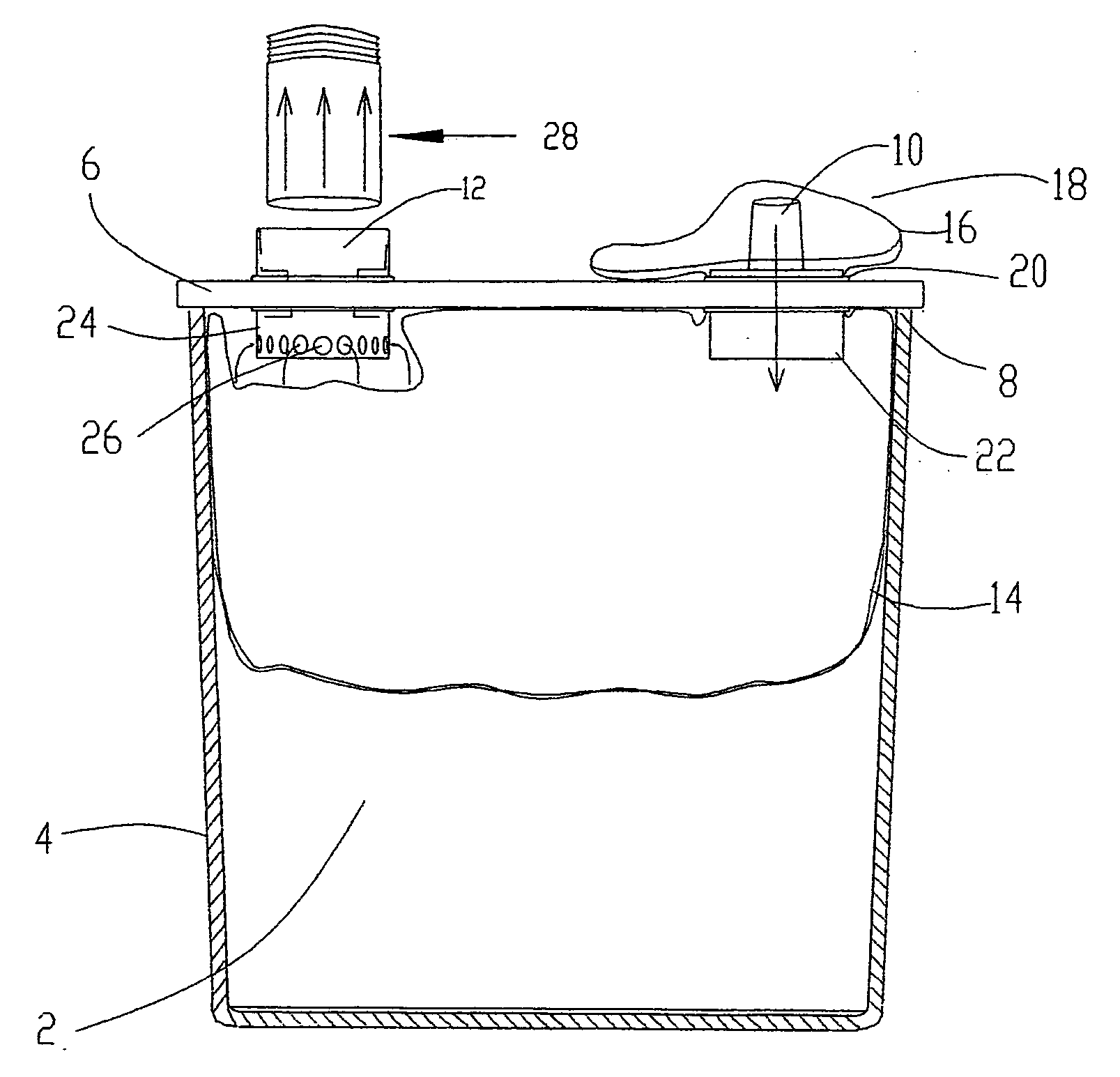

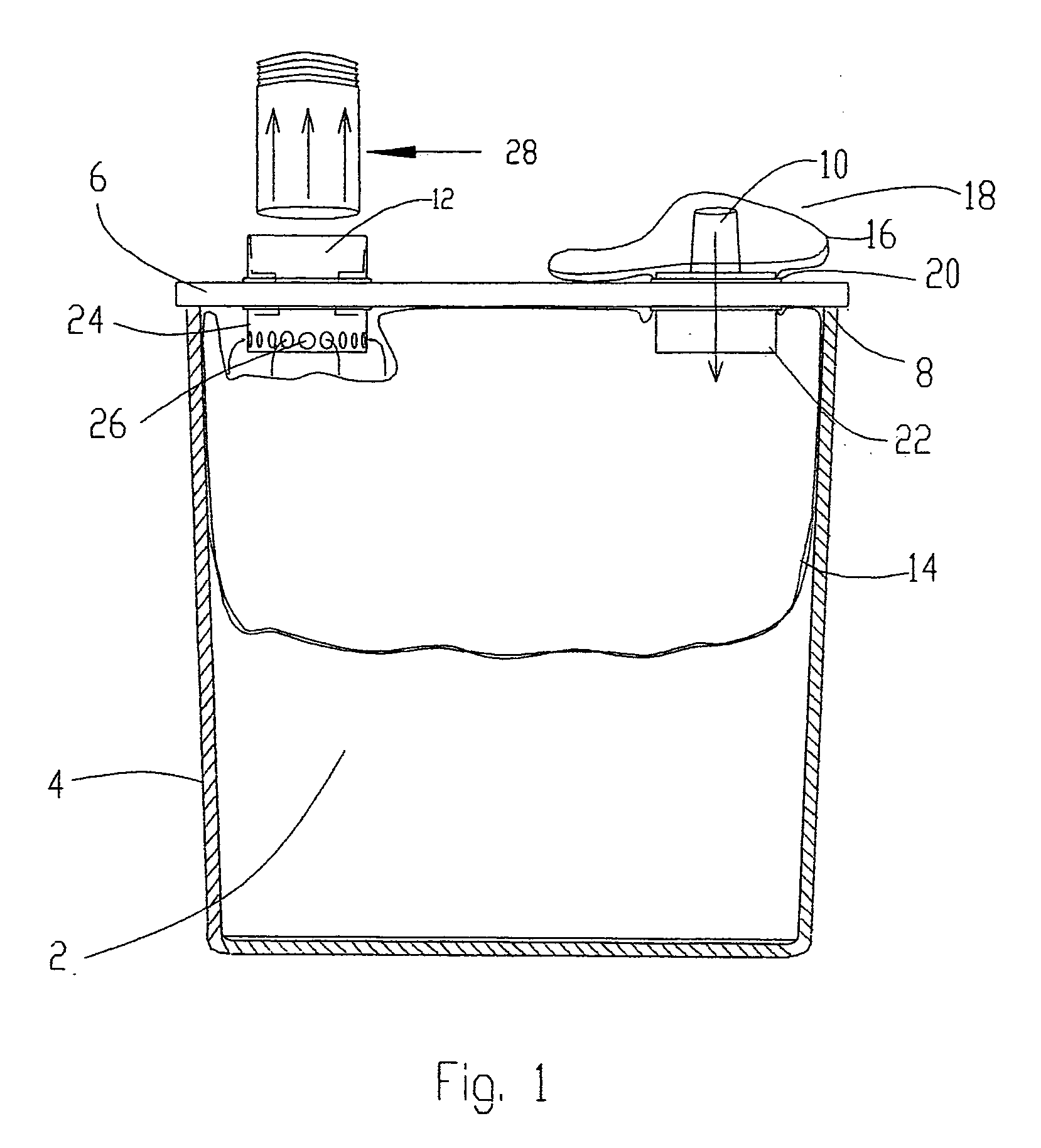

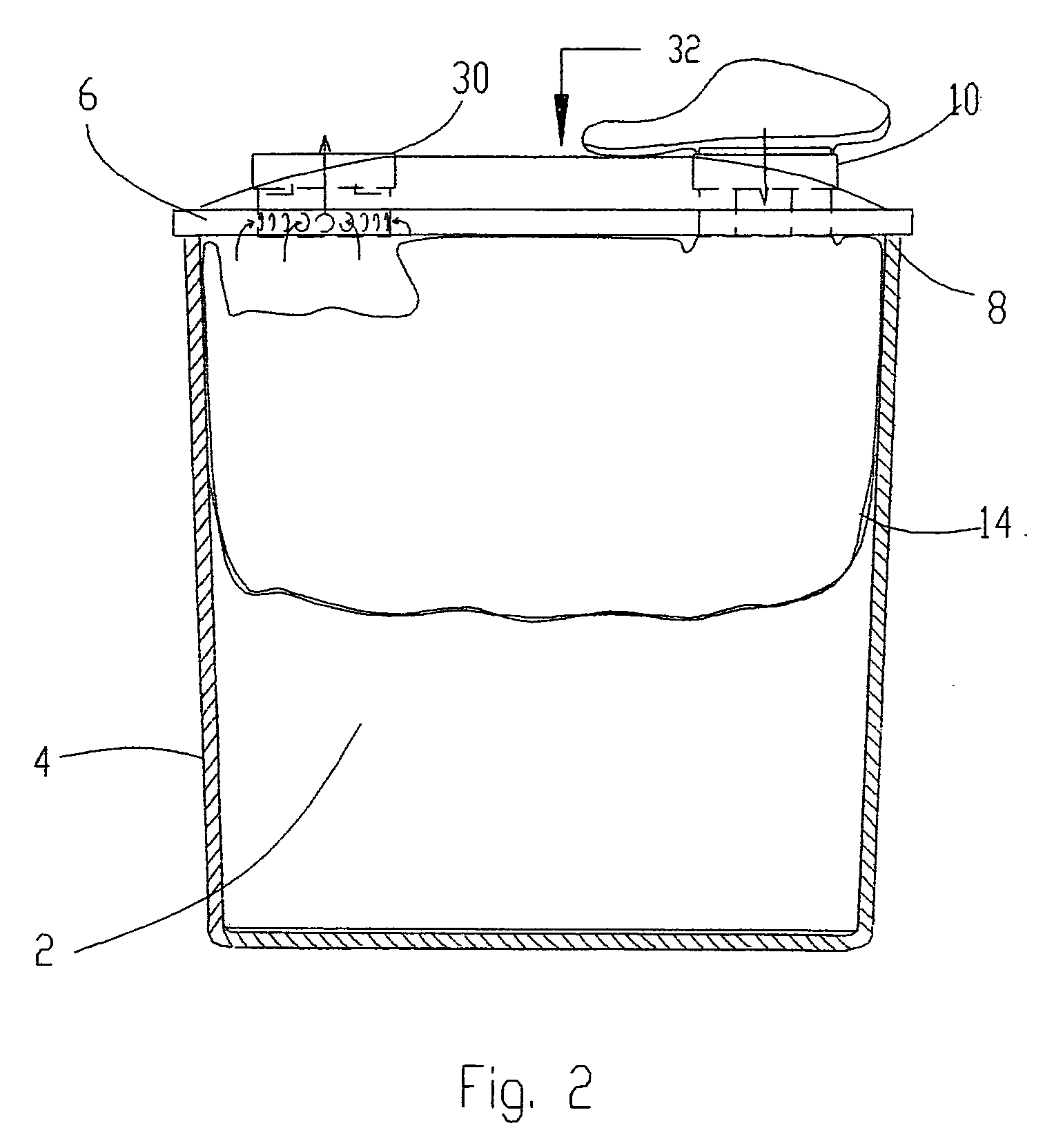

[0020]this invention is directed to keeping paste-like materials or liquids 2 in containers 4 such as pails or cans in a fresh condition during storage. Such material 2 is basically any material that is stored in the container 4 and has a tendency to dry out due to contact with air during storage. The container 4 is made of metal or plastic and is of conventional size of containers used in the art, such as one gallon or five gallon cans or pails. To accomplish this goal the invention uses a pre-sized lid 6, usually of plastic, which snaps onto the top edge 8 of the container 4.

[0021]In a first alternative of the first embodiment, shown in FIG. 1, the lid 6 for a container 4 has an inlet port 10 and an outlet port 12. A strong, flexible bag 14, conveniently a plastic bag, is fit through a first, inlet, port 10 so that the mouth 16 of the bag 14 will be toward the outside 18 of the container 4 when the lid 6 and the container 4 are joined. The bag 14 and the port 10 may be securely fa...

second embodiment

[0024]this invention is described with reference to FIG. 3. This embodiment provides a device 34 for pre-filtering dirty air before it comes in contact with the conventional filter within a wet / dry vacuum device (not shown). The device 34 of this invention provides longer useful operation time of the wet / dry vacuum device without clogging the filter medium. This device 34 has a container 36 such as a pail and a lid 38. The device 34 is based on the function of forcing dirty air into water 40 that is placed in the bottom 42 of the device 34. A conventional wet / dry vacuum attached to the device 34 by an outlet tube 44 is used to create a vacuum which is used to bring the dirty air into the container 36 by way of an intake tube 46. The origin of the dirty air may be an industrial tool 48 such as a sander or circular saw. The tool 48 is connected by means of an intake tube 46 having an appropriate inlet fitting 50 to the inlet port 52 of the pre-cleaning device 34. An inlet tube 54 is c...

third embodiment

[0026]the present invention will be described with reference to FIGS. 4 and 5. The third embodiment is a hand sander 64 of such construction as to provide a quick and efficient way to replace the sandpaper 66. A disengagement button 68 at the top 70 of the handle component 72 is operatively connected with a hook-like latch 74 which engages and disengages the handle component 72 and the bottom surface component 76 of the sander 64. Upon depression of the button 68, the bottom surface component 76 of the sander 64 is disengaged and swings open about a pivot point 78 at the rear of the sander 64. Alternatively, the sander 64 may be configured with a removable bottom surface component 76 that may be attached to the handle component 72 with any form of fastener. In either alternative, the bottom surface component 76 is constructed with horizontal slots 80 at both ends 82, 84. These slots 80 are for the purpose of accepting and holding the ends 86 of the sandpaper 66. As the bottom surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com