Fan structure for mounting in a light steel structure of a ceiling

a technology of light steel structure and fan structure, which is applied in the direction of machines/engines, liquid fuel engines, positive displacement liquid engines, etc., can solve the problems of reducing the amount of suction air, obstructing the planar beauty of the ceiling, and lowering the performance of the fan structur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

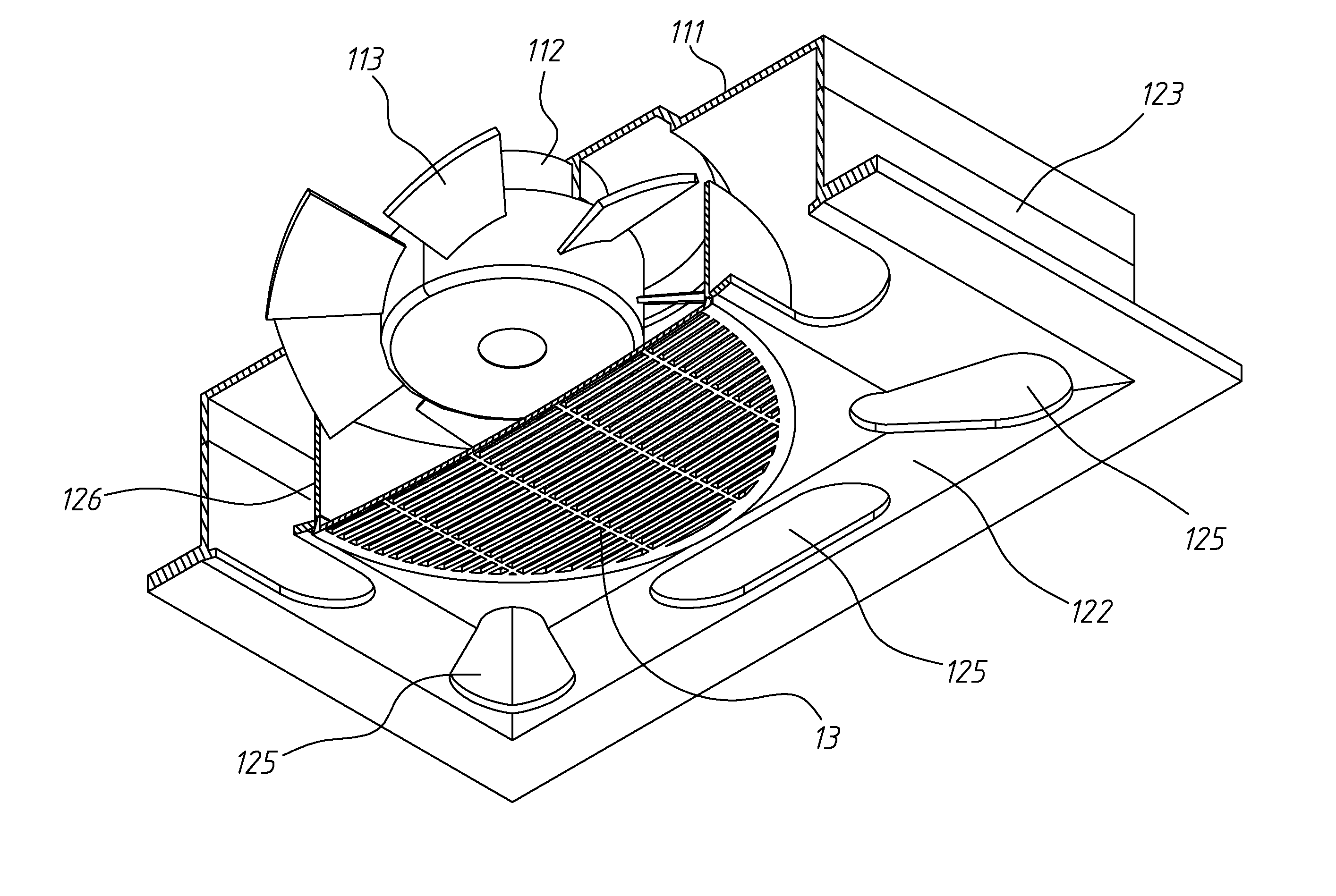

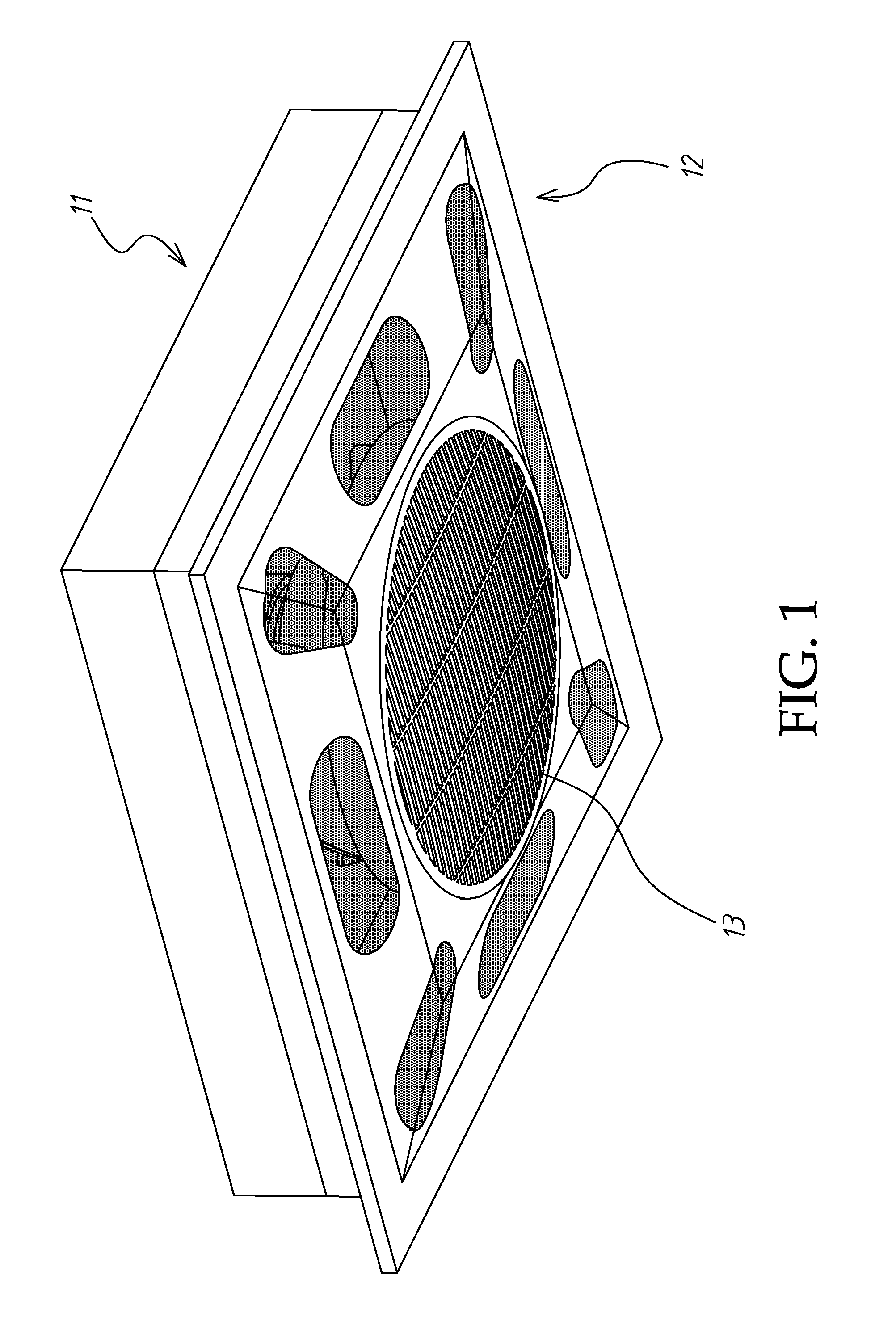

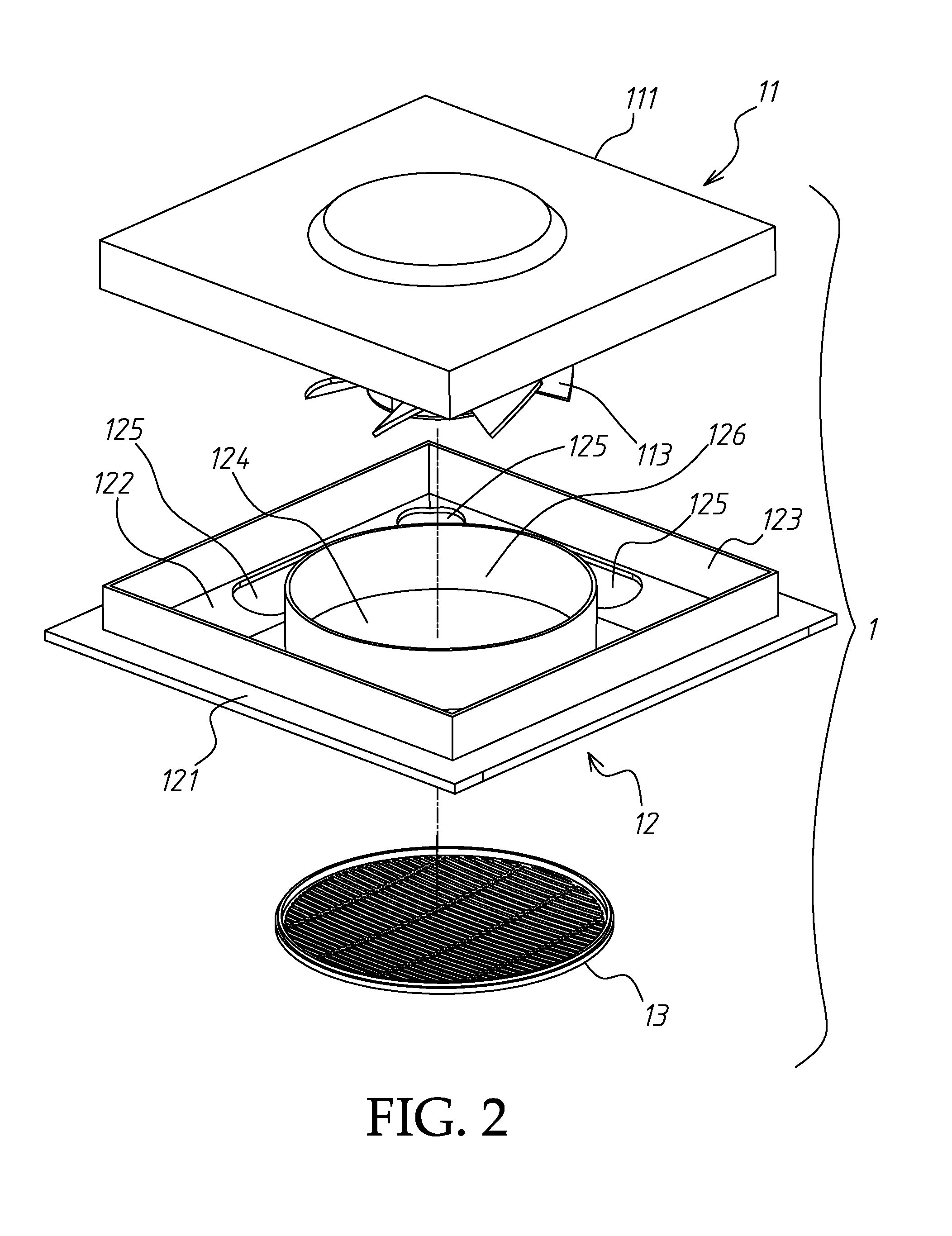

[0022]Referring to FIG. 5, a fan structure 1 is shown mounted in one frame sash of a light steel structure 2 of a ceiling 3. The fan structure 1 in accordance with the present invention, as shown in FIGS. 1˜3, is comprised of a fan holder 11, a bottom cover frame 12, and a grille 13.

[0023]The fan holder 11 comprises a top cover shell 111, a fan motor 112 mounted in the bottom side of the top cover shell 111, and a fan blade 113 coupled to the output shaft of the fan motor 112 and rotatable by the fan motor 112 to cause currents of air.

[0024]The bottom cover frame 12 comprises a smoothly arched bottom wall 122 curving smoothly downwards, a horizontal mounting flange 121 extending around the smoothly arched bottom wall 122 to facilitate installation of the fan structure 1 in one frame sash of the light steel structure 2 of the ceiling 3, a vertical connection flange 123 upwardly extending from the connection between the smoothly arched bottom wall 122 and the horizontal mounting flang...

second embodiment

[0036]Referring to FIG. 8, when the fan motor 112 of the fan structure 1 according to this second embodiment is electrically connected to rotate the fan blade 113, currents of air (see flow lines in the drawing) are produced to go from the outside into the inside of the bottom cover frame 12 through the ventilation holes 125 of the smoothly arched bottom wall 122 over the fence 126 and then to go toward the outside of the bottom cover frame 12 through the open spaces in the grille 13. At the same time, regulated cold air or hot air is continuously delivered out of the fan duct 4 and moved with the currents of air caused by the fan blade 113 through the grille 13 toward the indoor space.

[0037]FIG. 10 shows a fan structure in accordance with a third embodiment of the present invention. This third embodiment is substantially similar to the aforesaid second embodiment with the exception that the top cover shell 111 of the fan holder 11 of this third embodiment eliminates the aforesaid m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com