Bypass system to control liquid volume

a liquid volume control and bypass technology, applied in the direction of water supply tanks, pumping plants, domestic plumbing, etc., can solve the problems of reducing the volume, and affecting the bathing experien

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

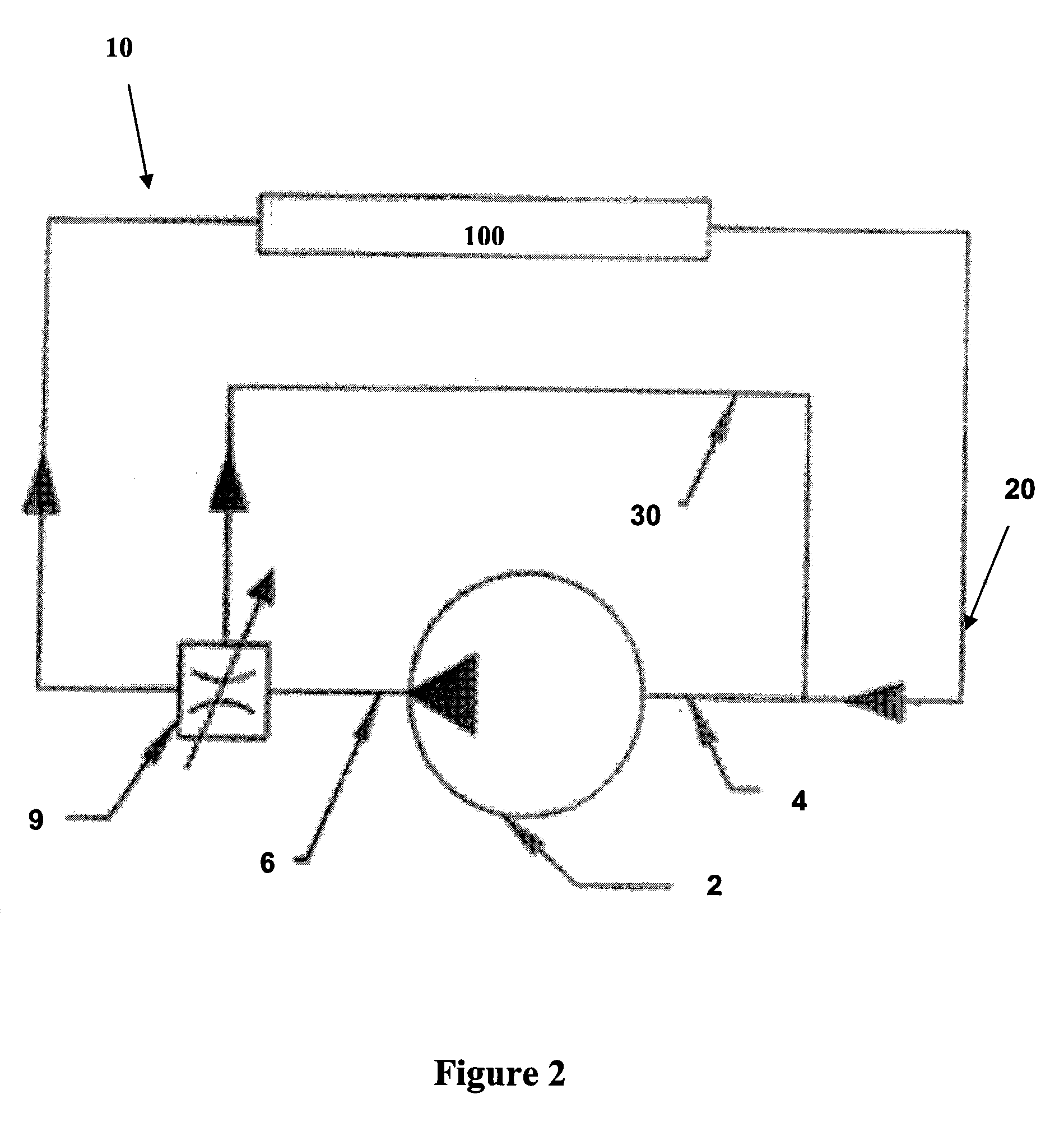

[0029]As may be seen in FIG. 2, which represents the present invention, the valve 9 is close to the outlet 6 of the pump 2 at a junction between the main loop 20 and the bypass loop 30. This valve 9 is a three-way valve which can divert, in different percentages, the liquid to the main loop 20 or the bypass loop 30.

second embodiment

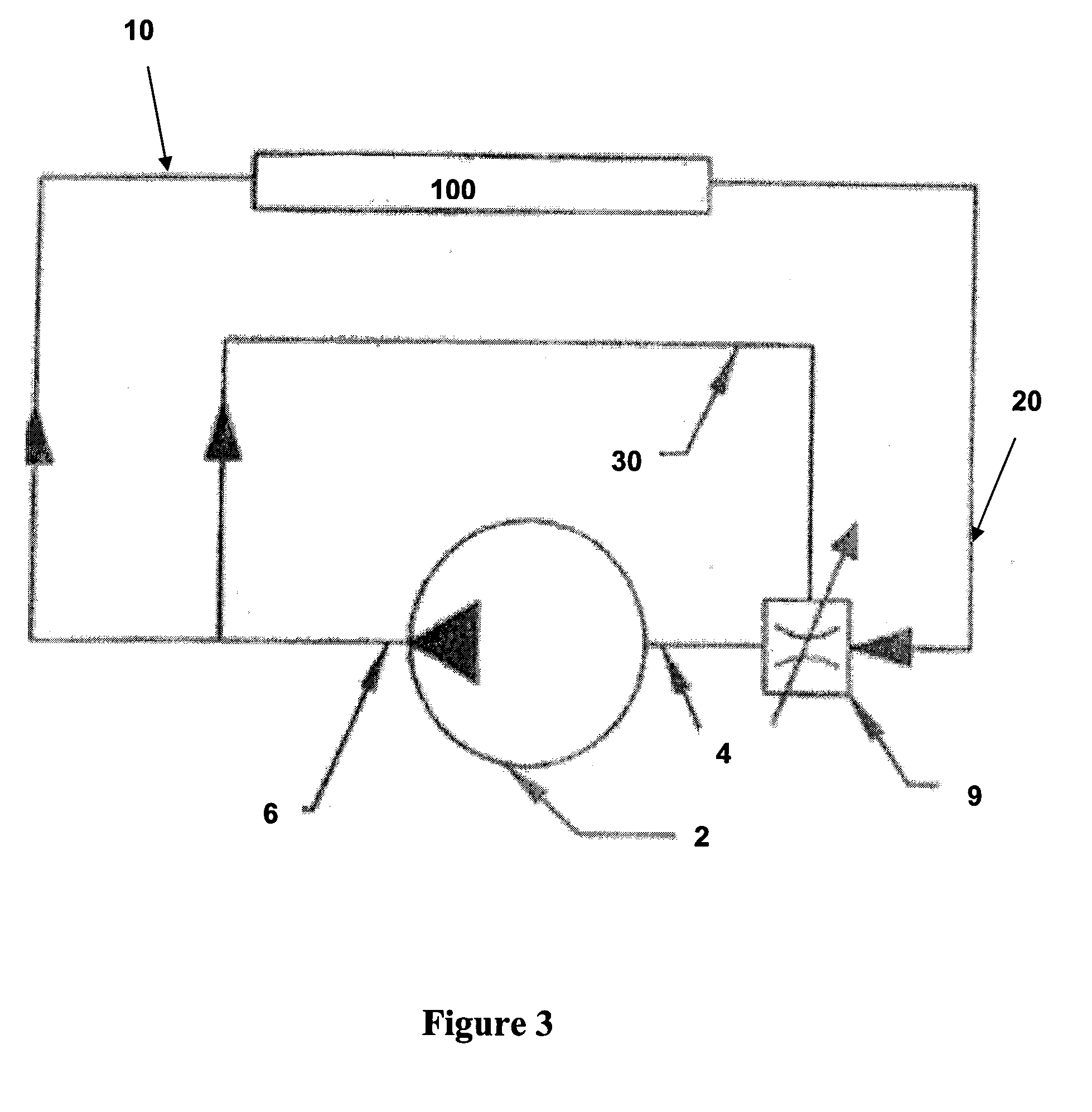

[0030]Turning now to FIG. 3, which shows the present invention, the valve 9 is close to the inlet 4 of the pump 2 at a junction between the main loop 20 and the bypass loop 30. This valve 9 is also three-way valve which can divert, in different percentage, the liquid to the main loop 20 or the bypass 30. The advantage of the configuration of this system is that even if the valve is in the intake side of the pump, the pump remains filled with liquid at all times, with the result that the efficiency or the cooling of the liquid-cooled motor remains unaffected by variations in water flow.

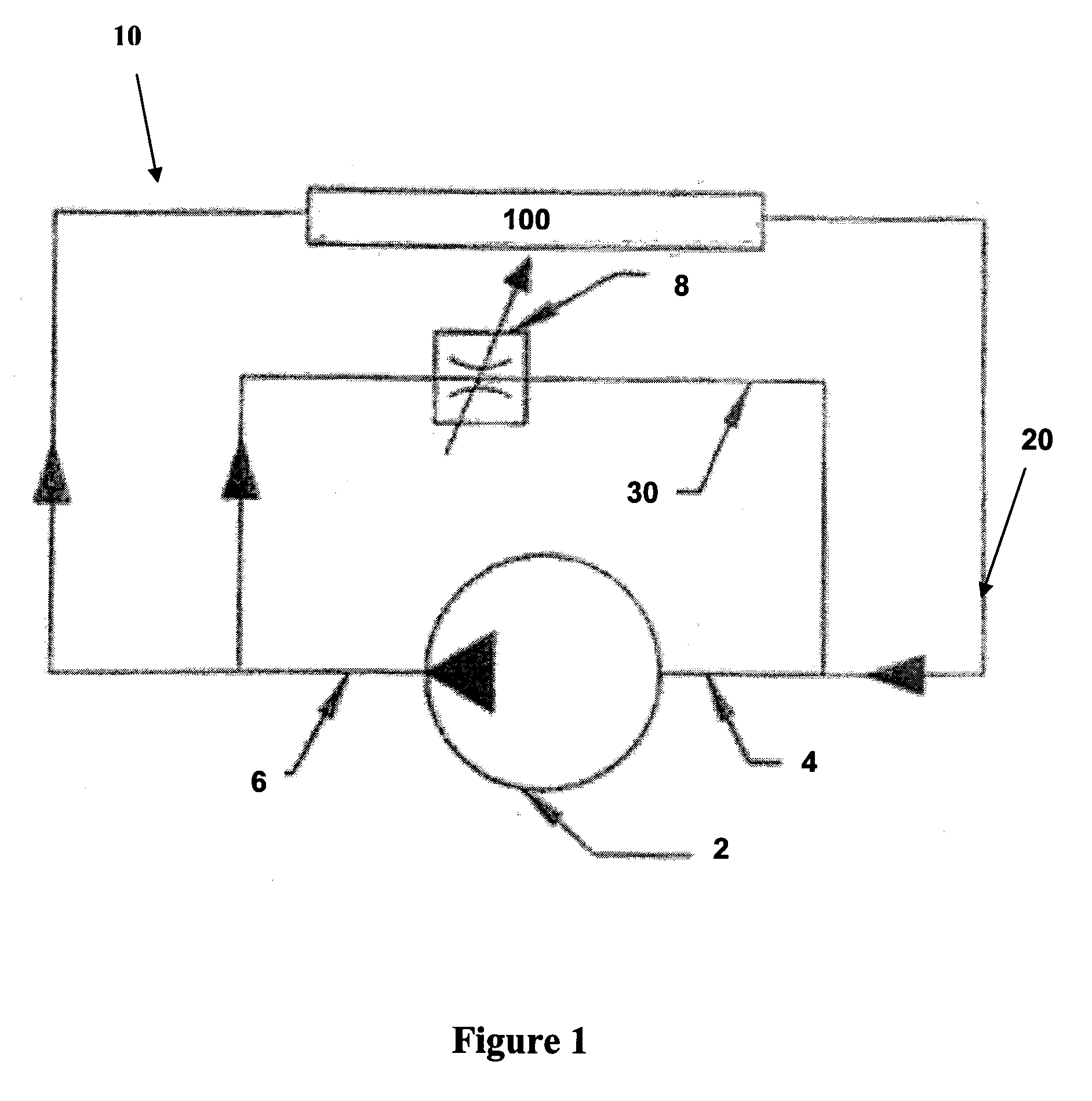

[0031]FIG. 4 shows a slightly more intricate arrangement of the bypass system illustrated in FIG. 1. Once again, the bypass system is shown generally by the numeral 10. The main and bypass loops are represented by the numerals 20 and 30, respectively. The pump 2 is preceded by an inlet 4 and followed by an outlet 6, and the valve and reservoir identified by the numerals 8 and 100, respectively. This ar...

third embodiment

[0032]the invention is shown in FIG. 5. The bypass system is represented generally by the numeral 10. This embodiment very closely resembles the embodiment illustrated in FIG. 2 by having a tri-way valve 9 positioned close to the outlet 6 of the pump 2. The inlet 4, main loop 20, bypass loop 30 and reservoir 100 are approximately in the same positions as in FIG. 2. An additional element of flow control has been introduced by including a second valve 8 in a new plumbing connection (or “bridge” element) 40 that has been established between the reservoir 100 and the bypass loop 30. This in effect allows an unlimited number of possibilities for varying the quantity of liquid entering the reservoir 100. The liquid inlet 40 in the reservoir 100 can supply a different function in the reservoir and have different pressure while still being supplied by only one pump. A variation of this embodiment would involve repositioning and replacement of the second valve 8, which is a two-way valve, by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com