Sample deposition device

a sample and deposition device technology, applied in the field of sample deposition devices, can solve the problems of reproducibility, affecting the quality of the sample, and affecting the dosing accuracy, so as to achieve the effect of compactness, reproducibility, and high degree of precision and reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

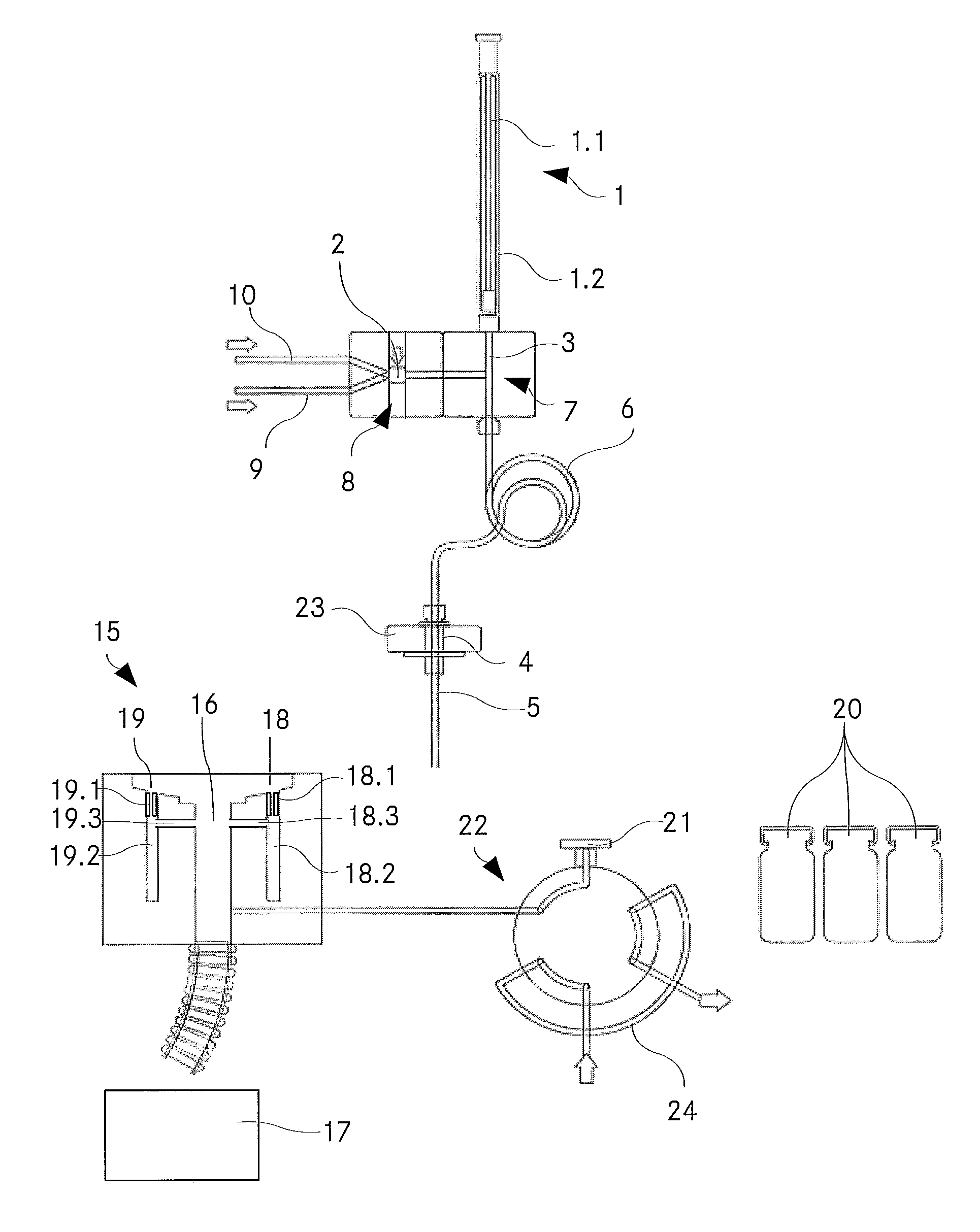

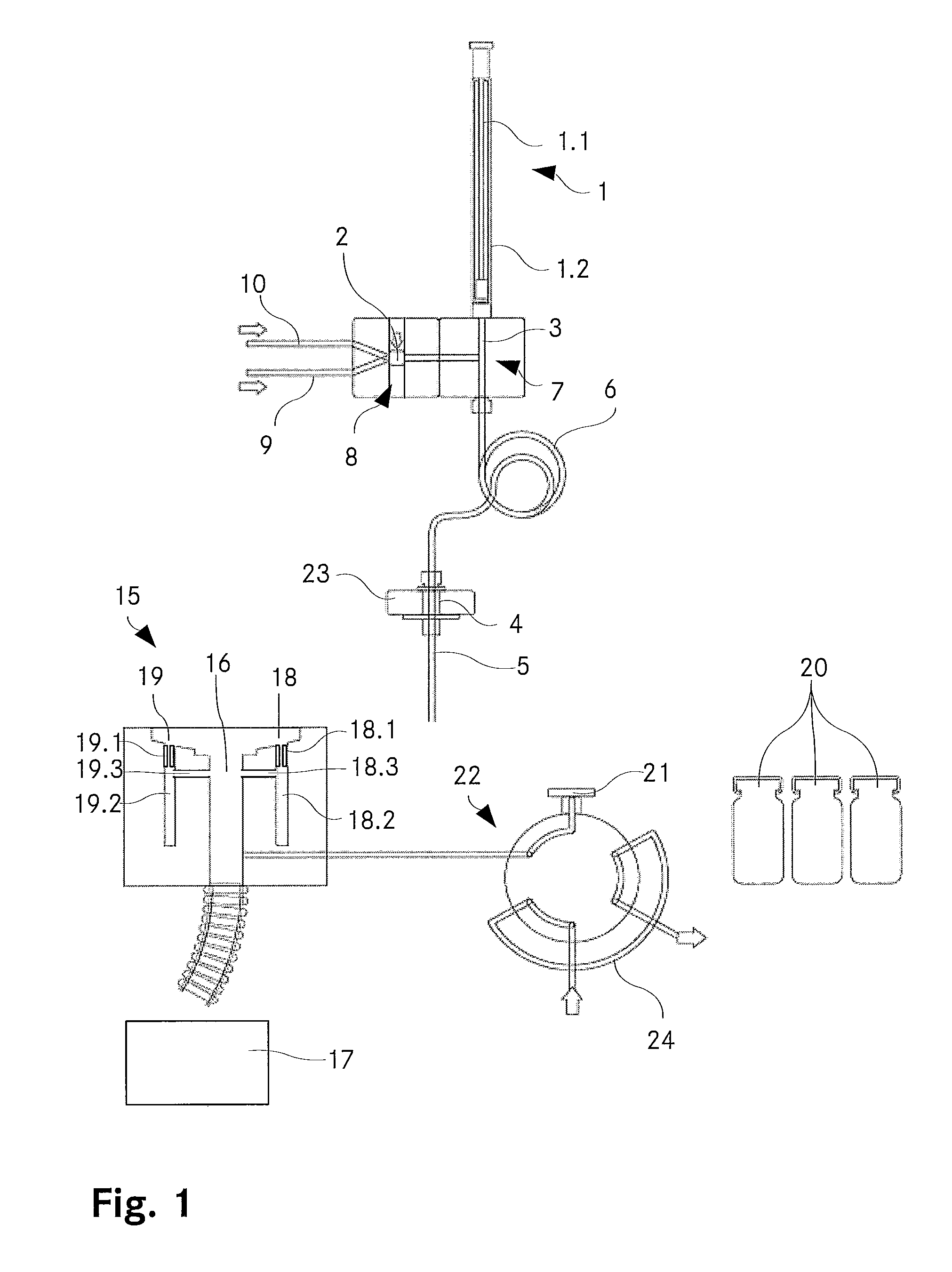

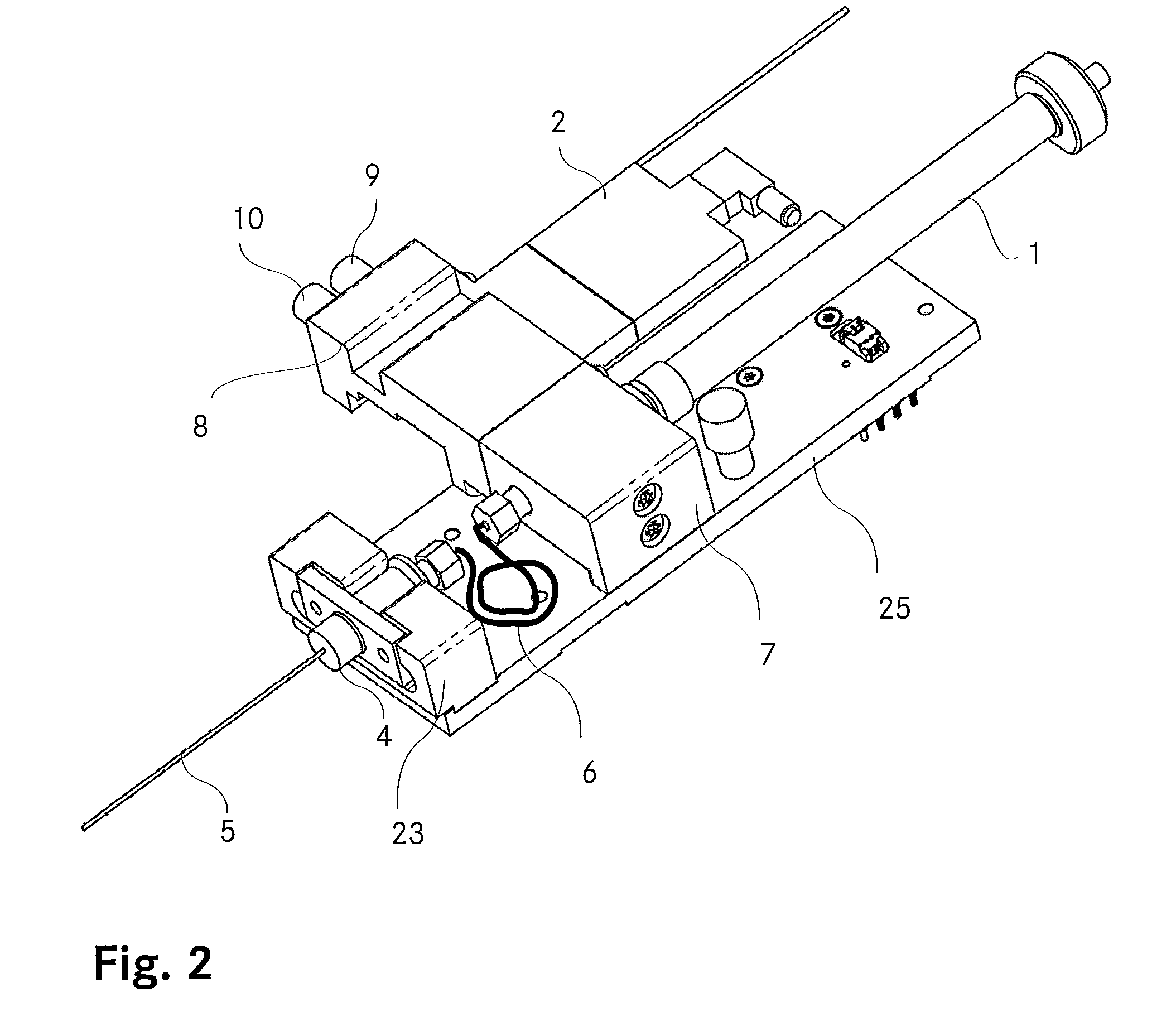

[0006]With measuring instruments (detectors) becoming ever more sensitive, there is a need for sample deposition systems that are much better than conventional systems in terms of cross-contamination, reproducibility, speed and long life (robustness).

[0007]The devices according to the prior art have the disadvantage that the injection needle cannot be efficiently cleaned. Furthermore, cross-contamination of the sample material can only be partially avoided. Finally, the sample volume to be collected cannot be reproduced in an optimal manner.

[0008]Therefore, the object of the invention is to make available a device belonging to the technical field mentioned in the introduction and also a corresponding cleaning method, which device and method ensure the least possible cross-contamination with at the same time a high degree of accuracy, speed and long life.

[0009]The object is achieved by the features of claim 1. According to the invention, a connection for fluid of the second connectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com