Seamless control of spring stiffness in a liquid spring system

a liquid spring and stiffness technology, applied in the field of vibration control systems, can solve problems such as destructive force of vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

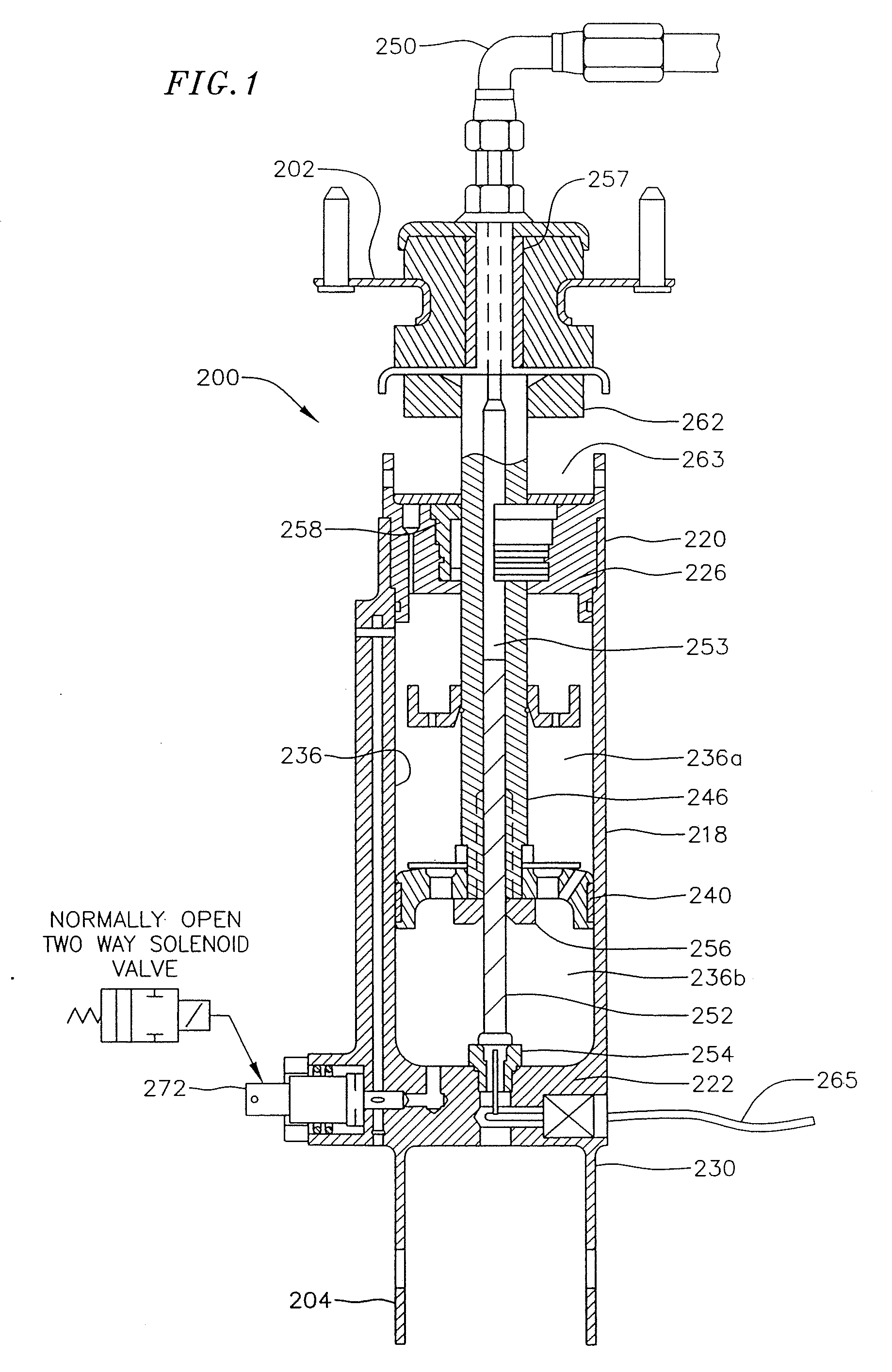

[0042]Schematically illustrated in FIG. 1 is a partially cross-sectional illustration of an adjustable liquid spring device, indicated generally at 200, which embodies principles of the present invention. Liquid spring 200 comprises a generally vertically oriented, single rod end type liquid spring. The present invention also comprehends the use of a double rod end type liquid spring as described in U.S. application Ser. No. 927,795 and incorporated herein by reference. The liquid spring 200 is connected by its upper end mounting bracket 202 to the vehicle frame (not shown), and by its lower end mounting bracket 204 to the support structure (not shown) of its associated wheel, and operates to provide the requisite suspension system spring and damping forces at its associated wheel location.

[0043]Liquid spring 200 includes an elongated, generally vertically oriented tubular housing 218 having an upper end 220 and a lower end 222. An upper annular gland member 226 is threaded into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com