Needle motion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

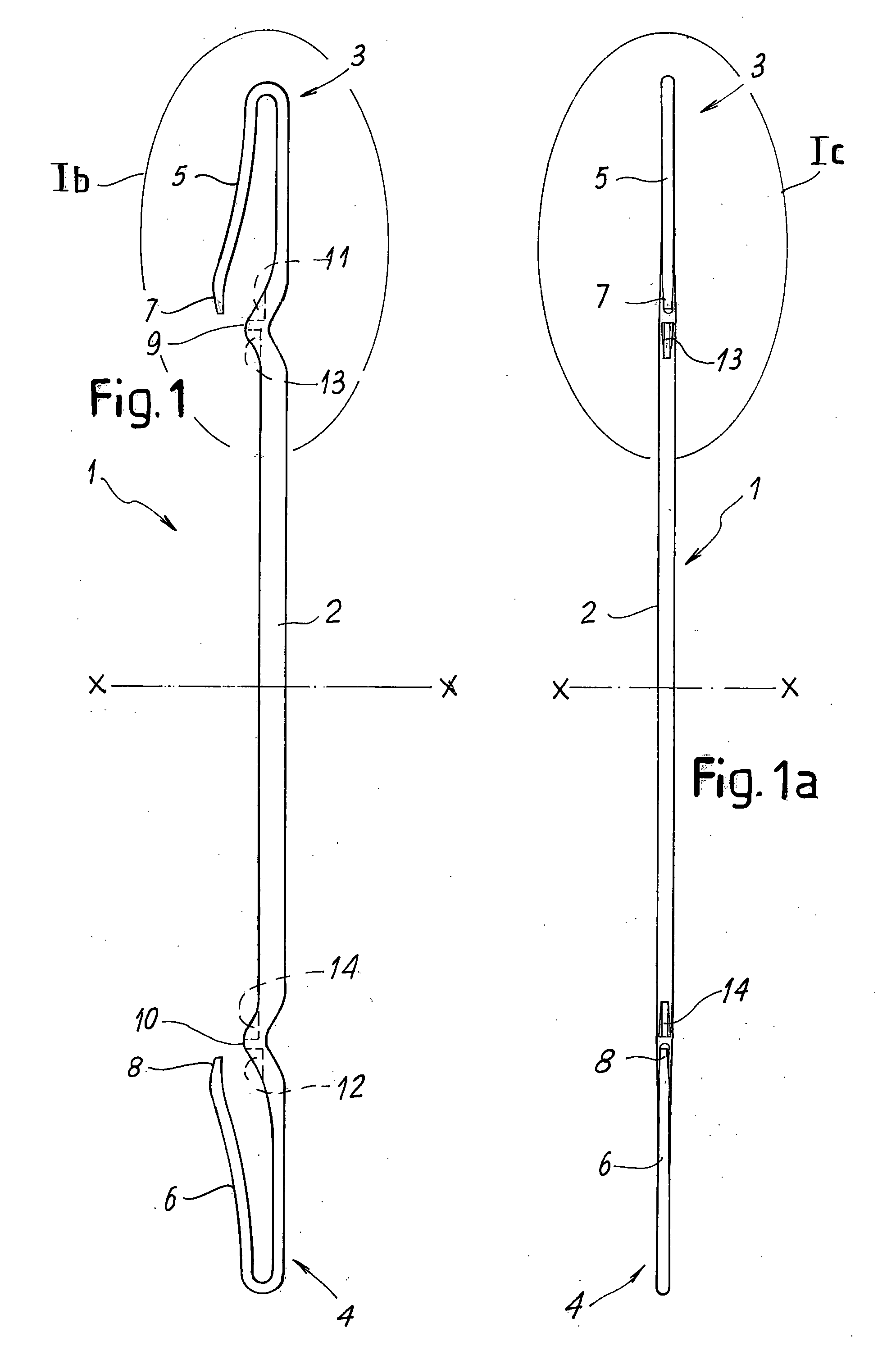

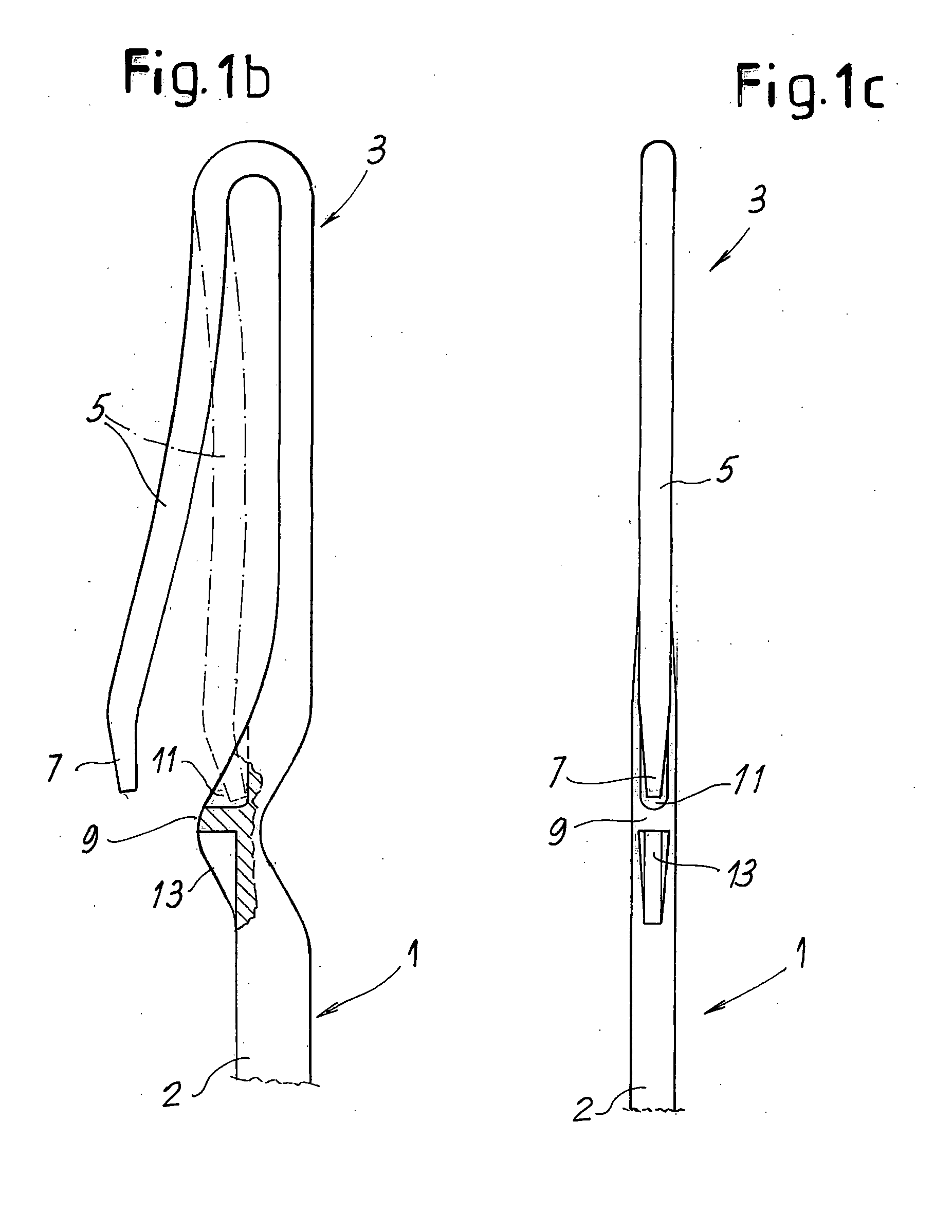

[0034]FIG. 1 shows a knitting needle according to the invention, which can be used in the needle motion according to the invention. The knitting needle 1 includes a stem 2 having opposedly arranged knitting heads, each including a respective knitting hook or beard 3, 4. Each hook or beard is shaped essentially in a fashion similar to known so-called “spring beard needles” or “bearded needles” or simply “spring needles”. Each hook or beard extends therefore forming an elastic buckle or spring buckle 5, 6 terminating at a tip 7, 8. The hook 1 is therefore a so-called “spring beard needle” or “bearded needle”, which however, contrary to the bearded needles of the prior art, is double, i.e. is provided with hooks at both ends of the stem. The needle can be formed of one piece of spring steel forming the stem 2 and the two long terminal hooks or beards 3, 4.

[0035]On the stem 2 of the knitting needle 1, reaching the position reached by each tip 7, 8 of the elastic buckles 5, 6 when the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com