Method Of Manufacturing A Crankshaft And A Half-Finished Crankshaft

a technology of crankshaft and crankshaft, which is applied in the field of crankshafts, can solve the problems of increasing strictness and increasing the cost of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

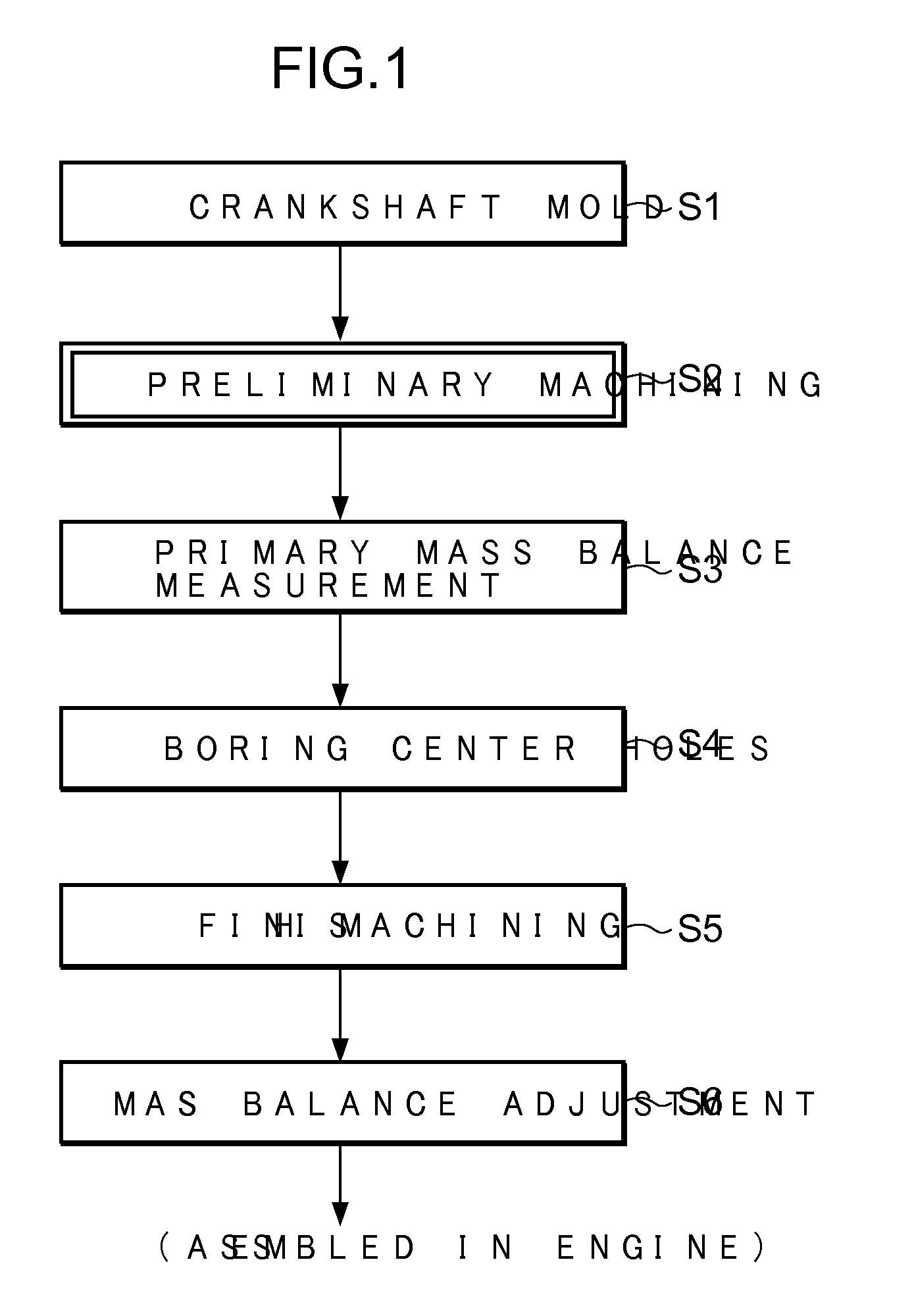

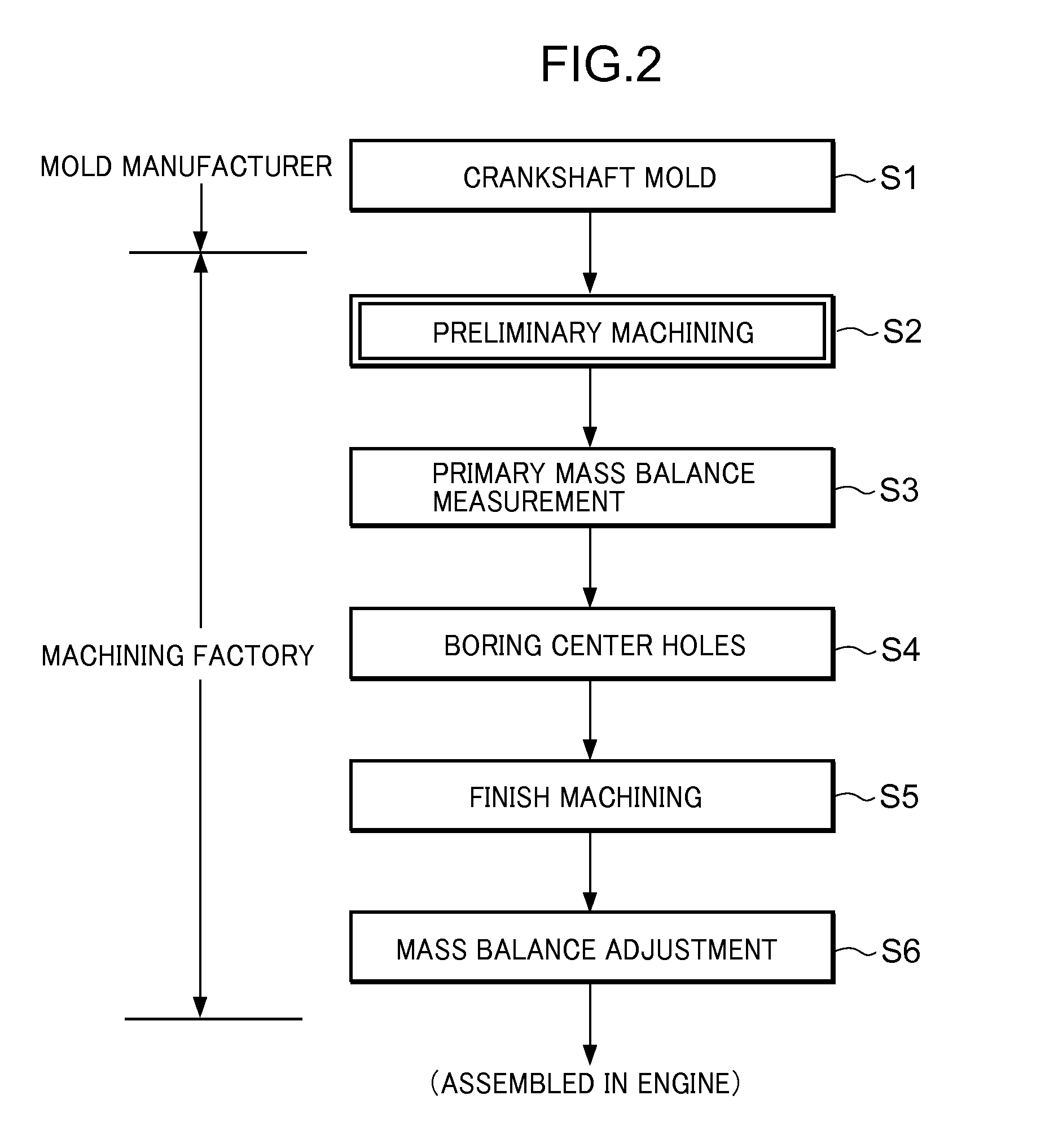

[0034]Preferred embodiments of the present invention will be described below with reference to the attached drawings. FIG. 6 is a flowchart showing a series of steps for manufacturing a forged crankshaft according to a first embodiment of the invention.

[0035]Steps S111 to S119 shown in FIG. 6 make up a process for preparing a half-finished crankshaft from a crankshaft blank. The process for preparing a half-finished crankshaft is carried out in a factory for manufacturing crankshaft molds (hereafter called a mold manufacturing factory as well). As apparent from comparison with FIG. 9 showing an existing manufacturing process, the embodiment of the present invention includes a preliminary machining step S117 interposed before primary mass balance measurement S118. In the preliminary machining step S117, a treated crankshaft mold, which is a ready-to-machine crankshaft stock, is subjected to machining at its balance weight portions. Balance weight portions of the treated crankshaft mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| draft angle | aaaaa | aaaaa |

| draft angle | aaaaa | aaaaa |

| draft angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com