Antifoam fuel additives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0056]A 950 number average molecular weight polybutenyl succinic anhydride was heated to 95° C. An oil slurry of aminoguanidine bicarbonate (AGBC) was added over a 45 minute period. The mixture was heated under vacuum to 160° C. and held at that temperature for about 6 hours, removing water and carbon dioxide. The resulting mixture was filtered. It is believed, without being limited by theory, that the resultant mixture comprises an aminotriazole as described herein.

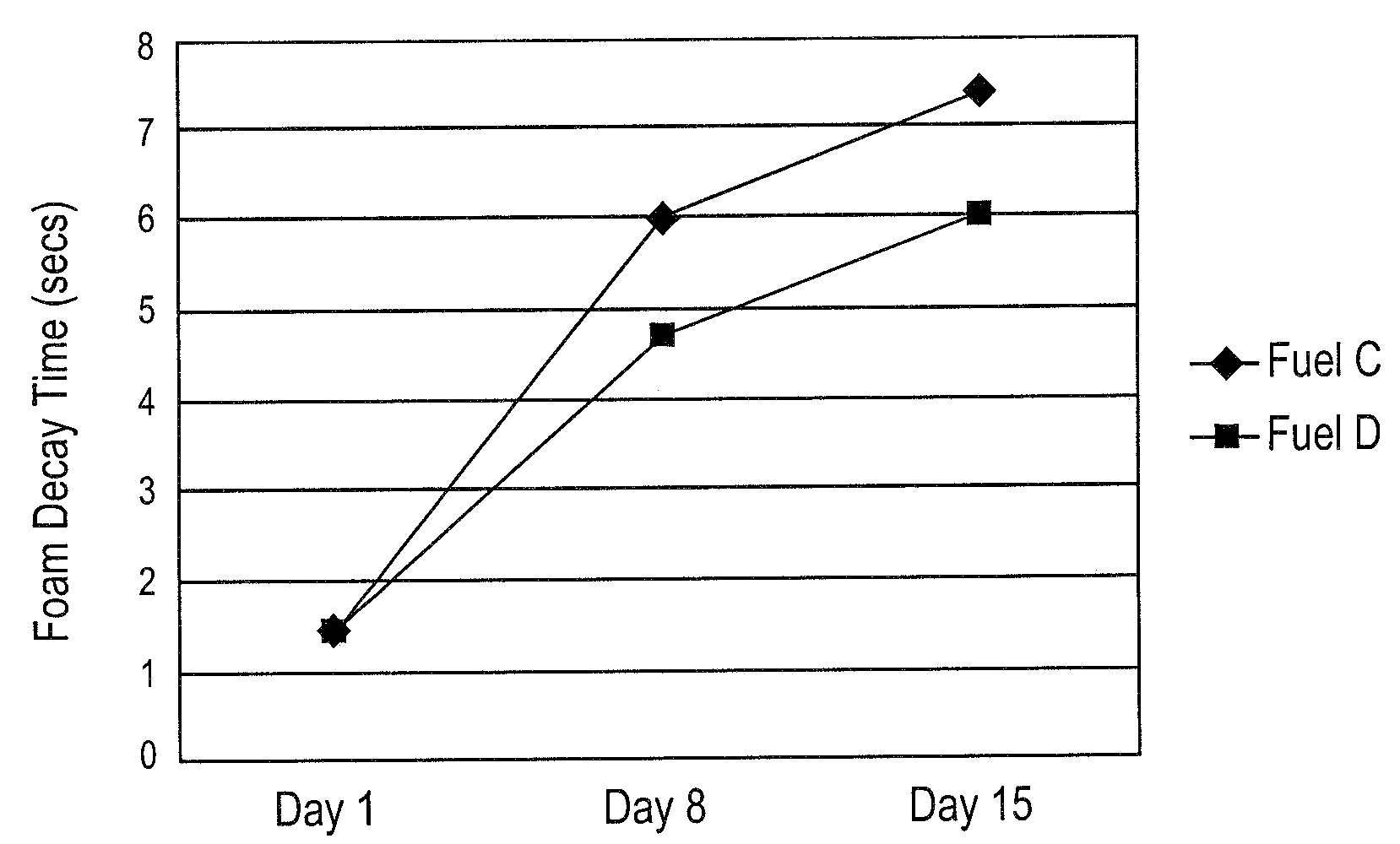

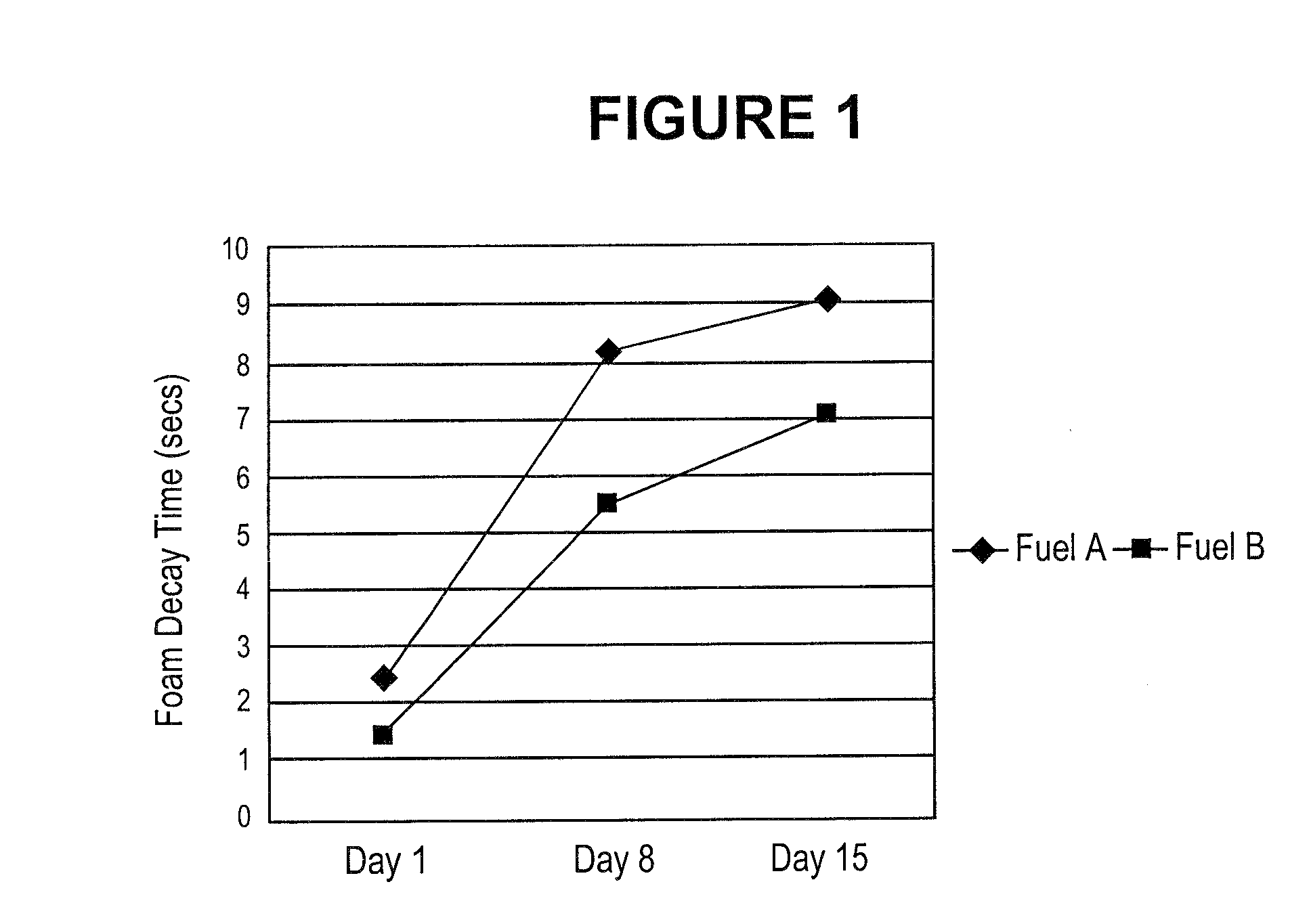

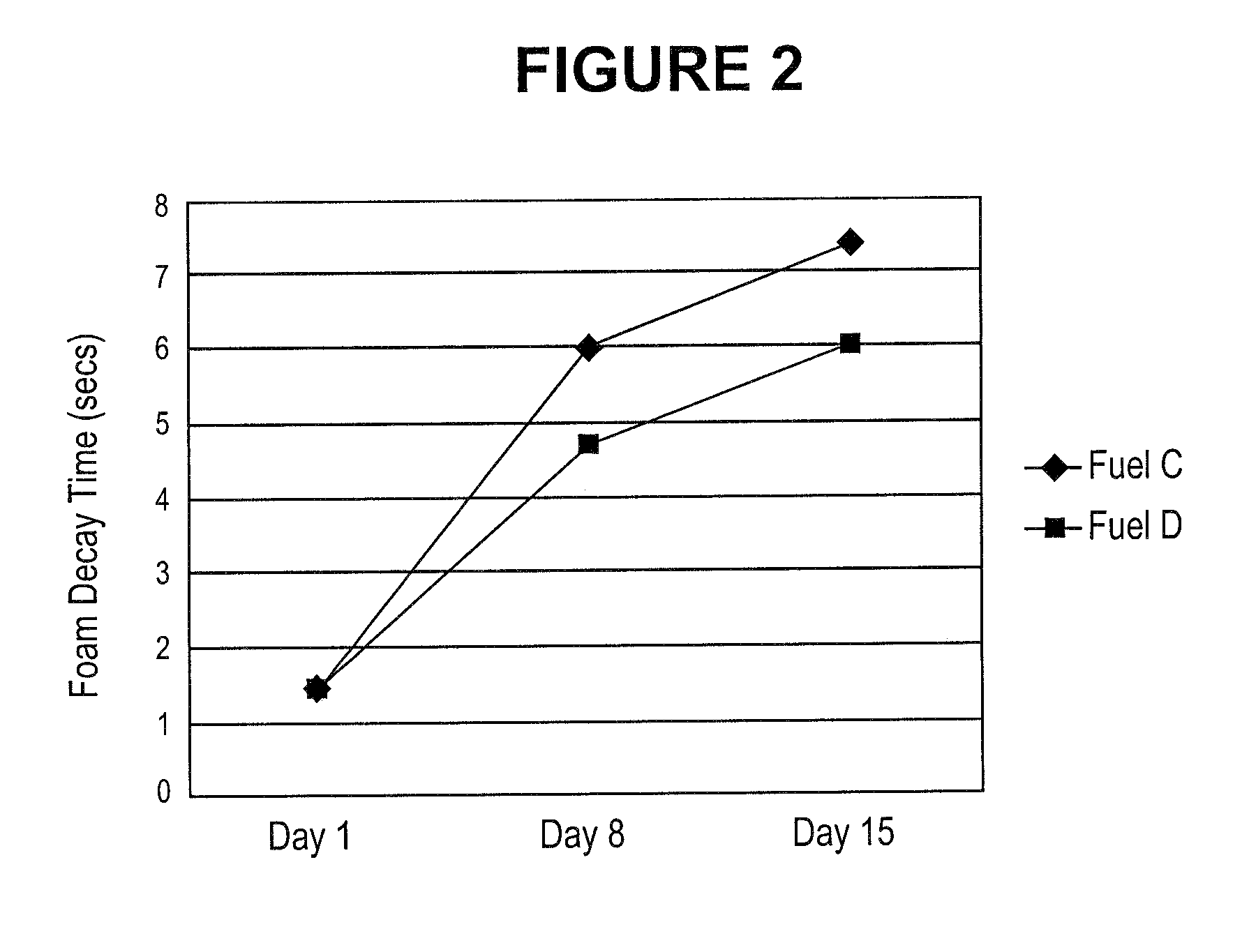

[0057]In the following examples, various base diesel fuels were each combined with various additives as described in Table 1, including the aminotriazole mixture described above, to produce fuel formulations that were evaluated for foam decay as described below.

TABLE 1Additive (mg / kg)Fuel AFuel BFuel CFuel DDispersant142.1042.1042.1042.10Aminotriazole Antifoam Agent0.005.000.005.00Solvent A220.0020.0075.5075.50Solvent B3132.00132.00103.90103.90Siloxane Antifoam Agent8.008.008.008.00Demulsifier A3.003.003.003.00Demulsifie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com