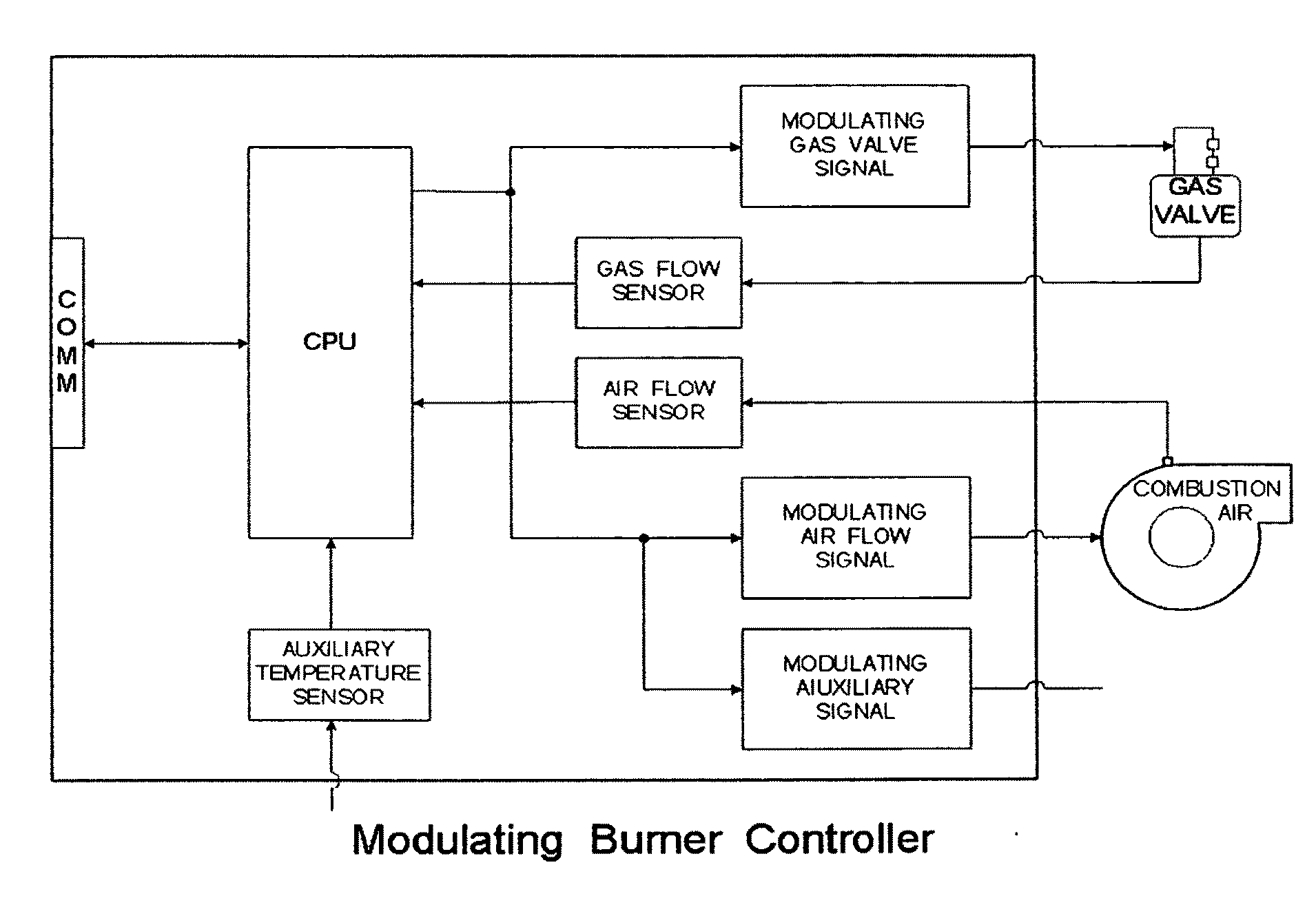

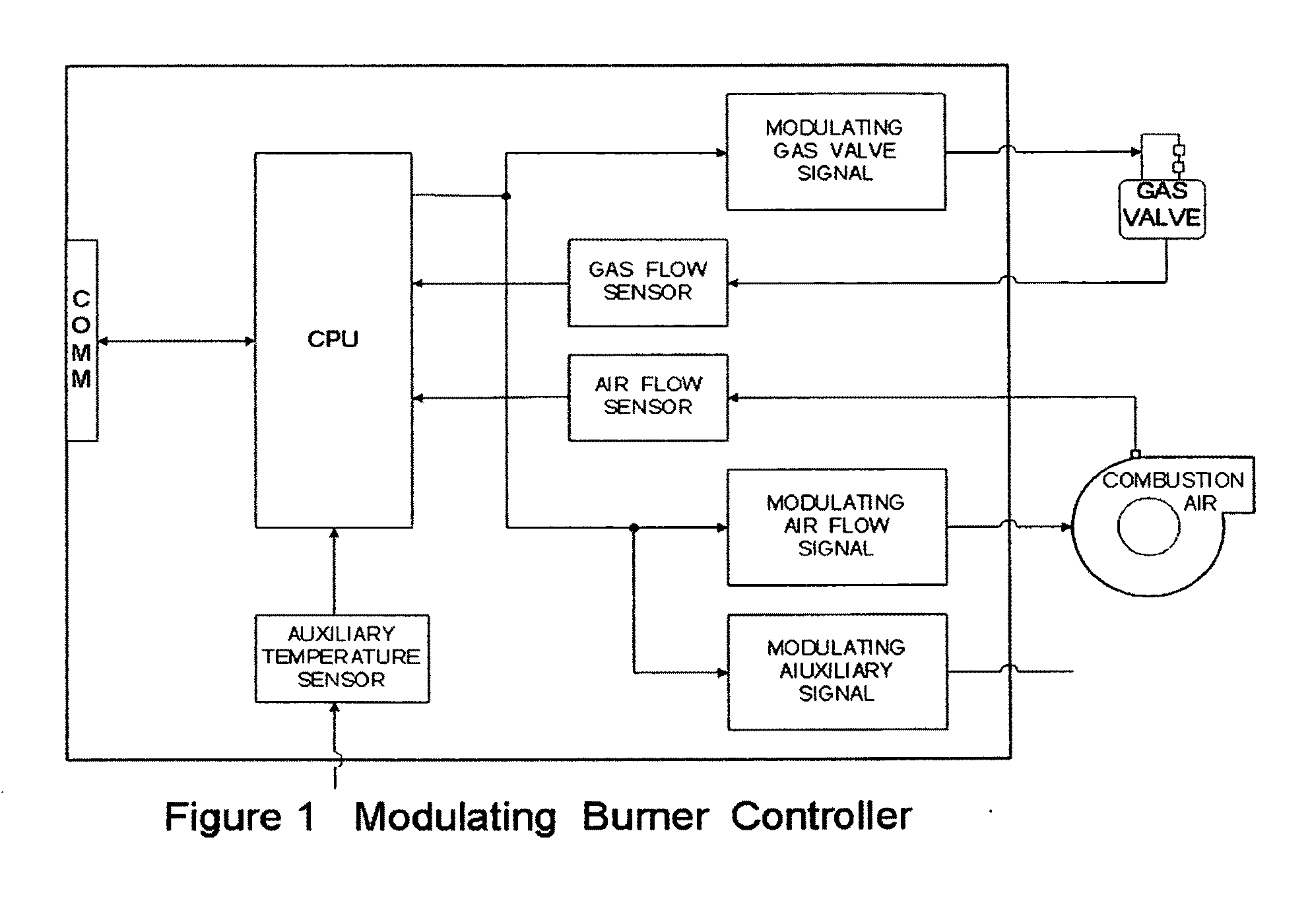

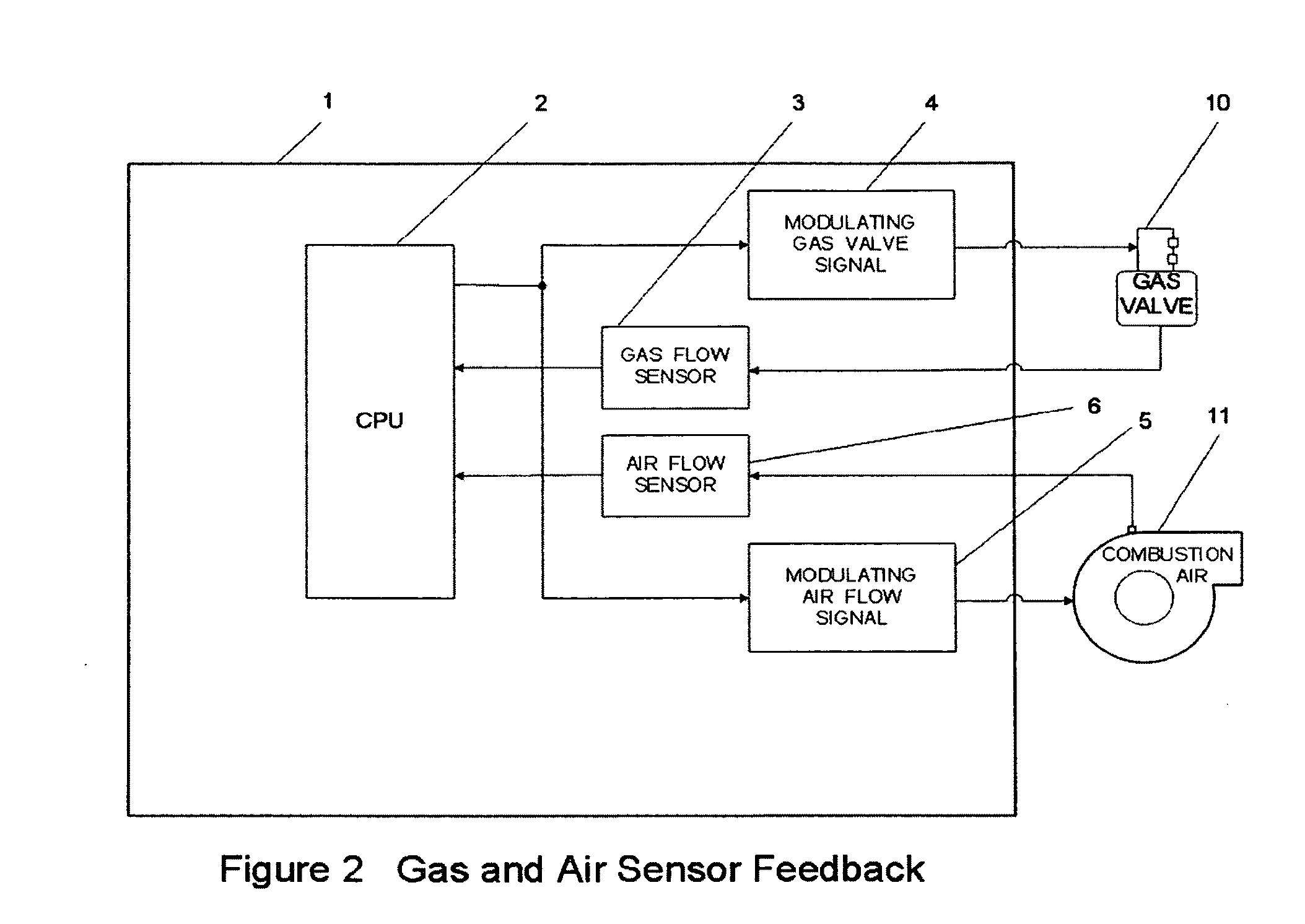

Apparatus and method for a modulating burner controller

a burner controller and apparatus technology, applied in the field of control systems, can solve the problems of not addressing modulation over a broad range of operating parameters of the yoshihiko, and achieve the effects of low cost, high turndown capability, and cost effective control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024]In some embodiments, the invention relates to burners or combustion devices, such as furnaces, heaters, forced warm air applications, water heaters, boilers, power burners, kilns, ovens, process furnaces, gas turbines, internal combustion engines, and / or the like. The apparatus and the method can provide control of a burner beyond merely supplying fuel and providing air for combustion at a fixed flow rate while igniting the mixture. Desirably, the apparatus and the method allow for efficient operation over a wide or broad range of operation or firing.

[0025]Furnaces may include any suitable size and / or configuration. Residential furnaces may include any suitable capacity, such as less than about 41 kilowatts (about 140,000 british thermal units per hour). Commercial furnaces may include any suitable capacity, such as greater than about 58 kilowatts (about 200,000 british thermal units per hour). Additional furnaces or units may be staged, such as to add or supply additional cap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com