Spatially distributed ventilation boundary using electrohydrodynamic fluid accelerators

a fluid accelerator and electrohydrodynamic technology, applied in the field of thermal management, can solve the problems of impracticality of conventional fan or blower ventilation, and achieve the effects of facilitating compelling product design, reducing volume and mass, and being thinner and lighter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

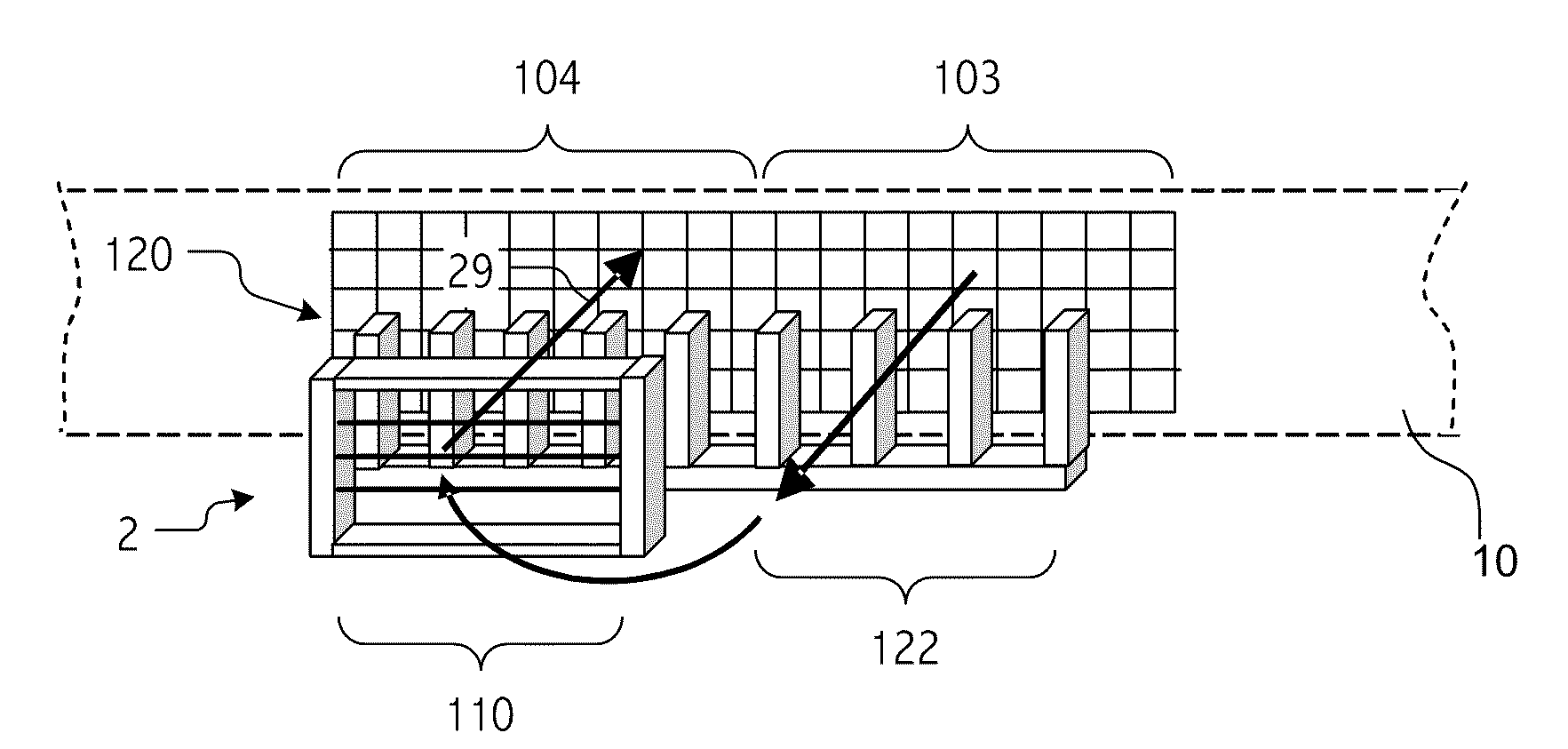

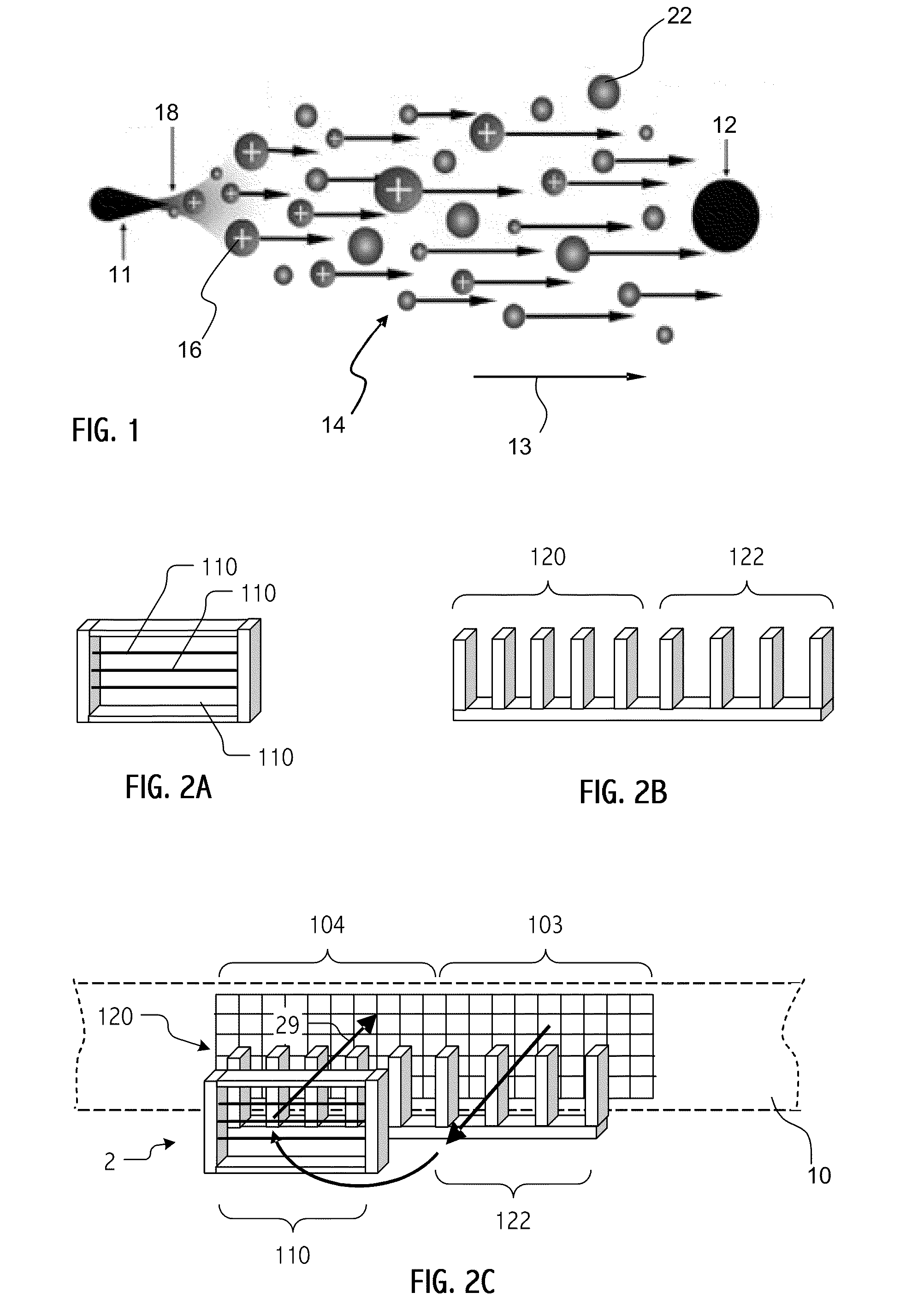

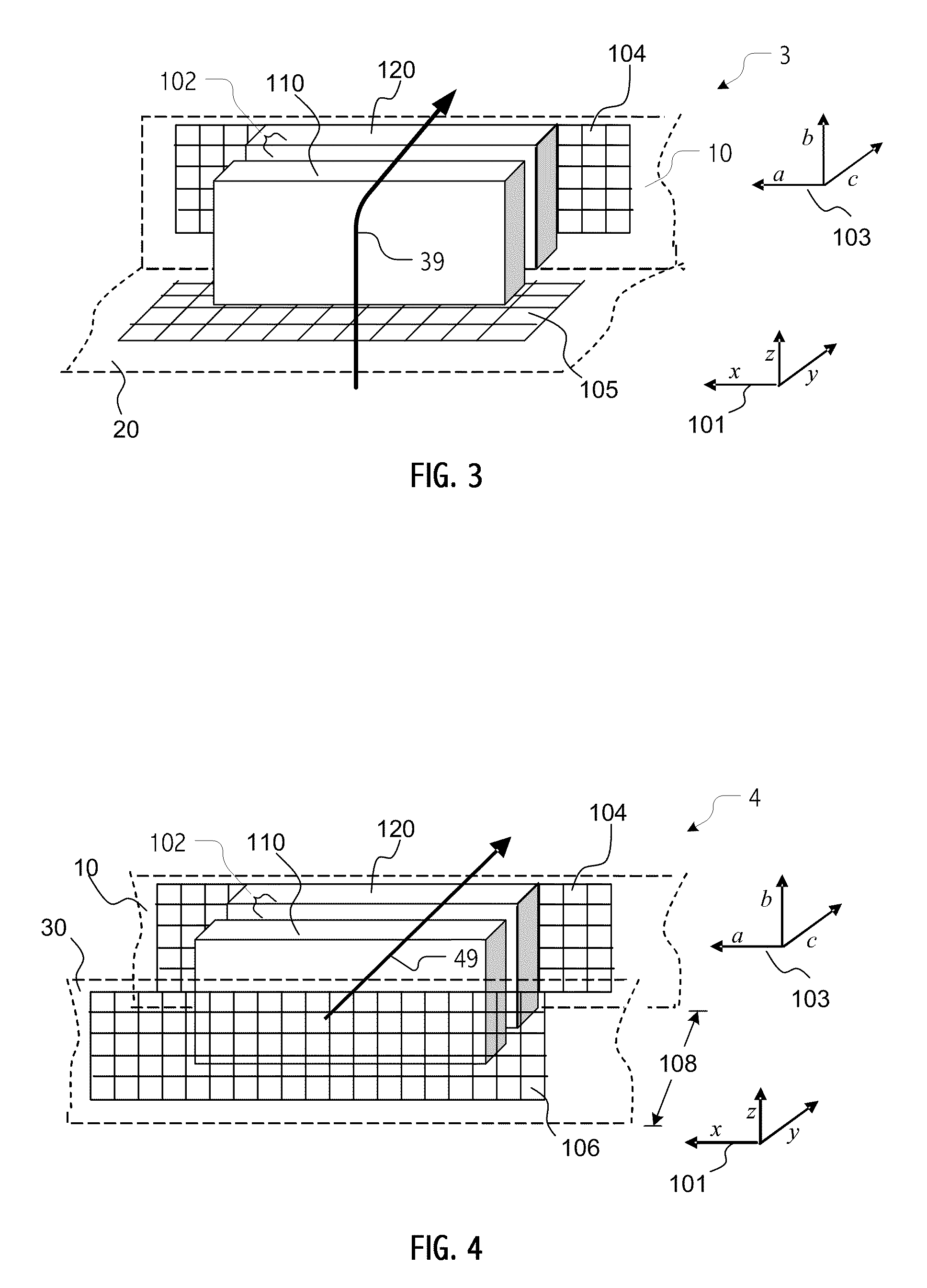

[0043]Thermal management systems described herein employ EHD devices to motivate flow of air between ventilated boundary portions of an enclosure. In this way, heat dissipated by electronics (e.g., microprocessors, graphics units, etc.) and other components may be transferred to the air flow and exhausted. Typically, the thermal management system includes heat transfer paths (often implemented as heat pipes or using other technologies) to transfer heat from where it is dissipated (or generated) to a location (or locations) within the enclosure where air flow motivated by an EHD device (or devices) flows over heat transfer surfaces.

[0044]As described herein relative to certain illustrative embodiments, some heat transfer surfaces may act as collector electrodes and participate in EHD acceleration of fluid flow (typically air flow), while additional heat transfer surfaces are provided that do not substantially contribute to motivation of fluid flow. Those heat transfer surfaces that a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com