Reconfigurable jet pump

a jet pump and configuration technology, applied in the direction of jet pumps, machines/engines, non-positive displacement pumps, etc., can solve the problems of inability to quickly respond to the needs of customers, inability to manufacture, and fixed configuration of the diffuser, etc., to achieve the effect of high degree of accuracy, low cost and high degree of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019]Selected embodiments of the present invention will now be explained with reference to drawings. In the drawings, identical components are provided with identical reference symbols. It will be apparent to those skilled in the art from this disclosure that the following descriptions of the embodiments of the present invention are merely exemplary in nature and are in no way intended to limit the invention, its application, or uses.

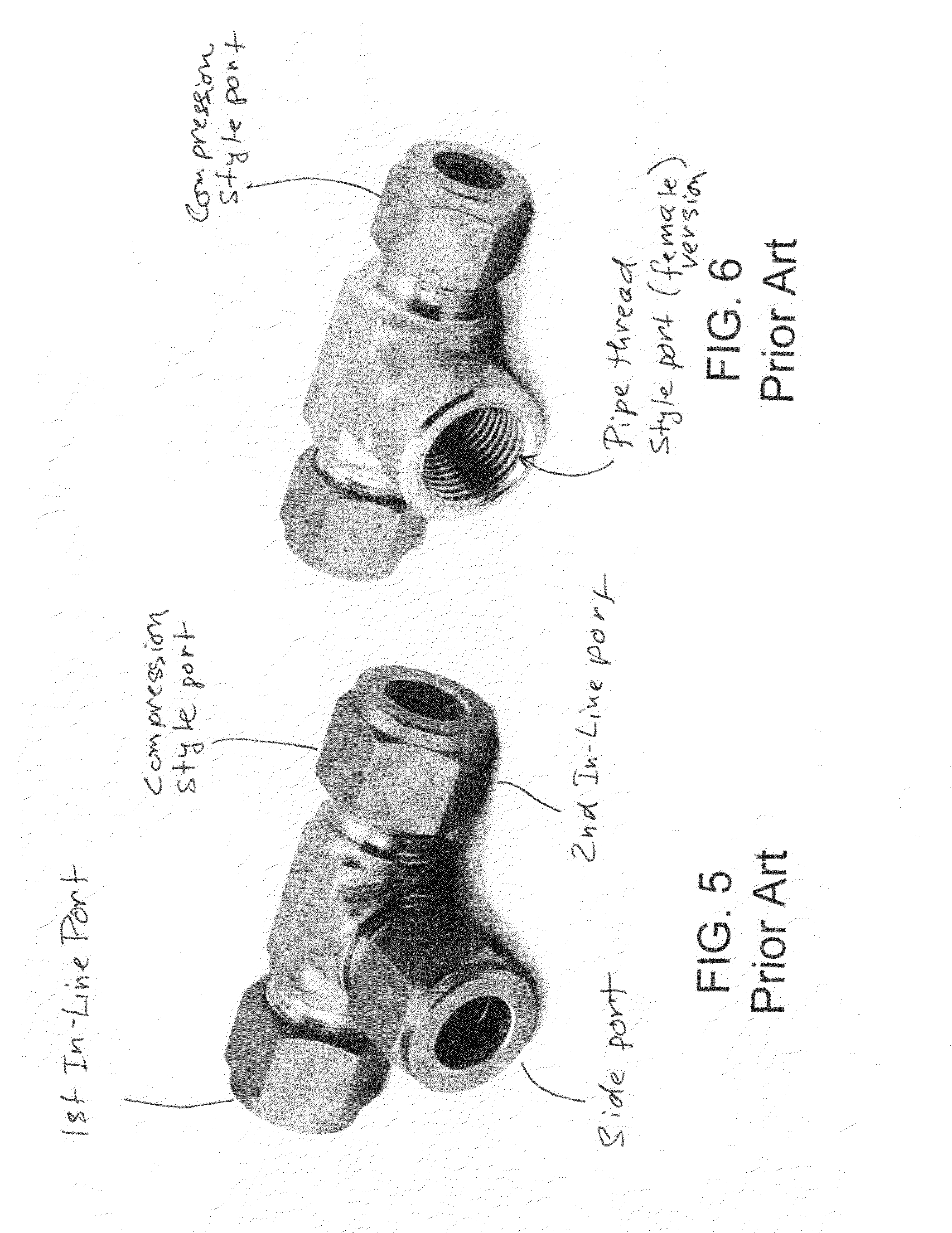

[0020]Referring now to FIG. 7, there is shown a cross-sectional view through a jet pump 100. The jet pump 100 comprises a fitting body 102, a nozzle. element 104, and a diffuser element 106. The fitting body 102 is preferably a T-shape tube fitting having a first compression type port 108 and a second compression port 110, with the two ports being arranged in-line. Compression style ports typically comprise a hollow threaded nut 109 and a mating thread 111 on the fitting body 102. As already noted, this type of fitting allows for precise axial alignmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com