Low Flush Toilet with Bowl Venting

a toilet and bowl technology, applied in water closets, water installations, water closets, etc., can solve the problem of not allowing malodorous sewer gases to rise from the sewer drain pipe, and achieve the effect of avoiding water wastage from dripping or leaking, and simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

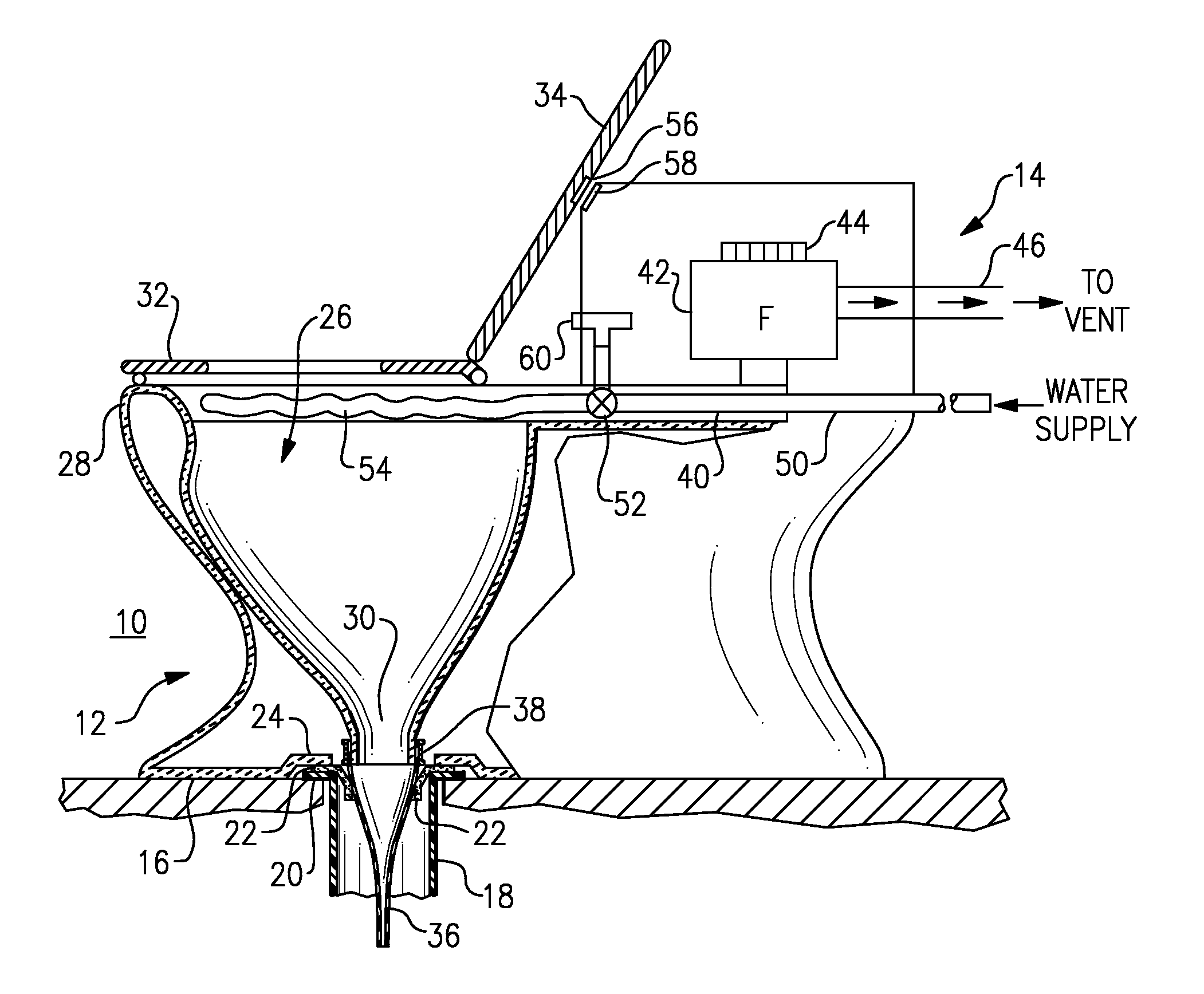

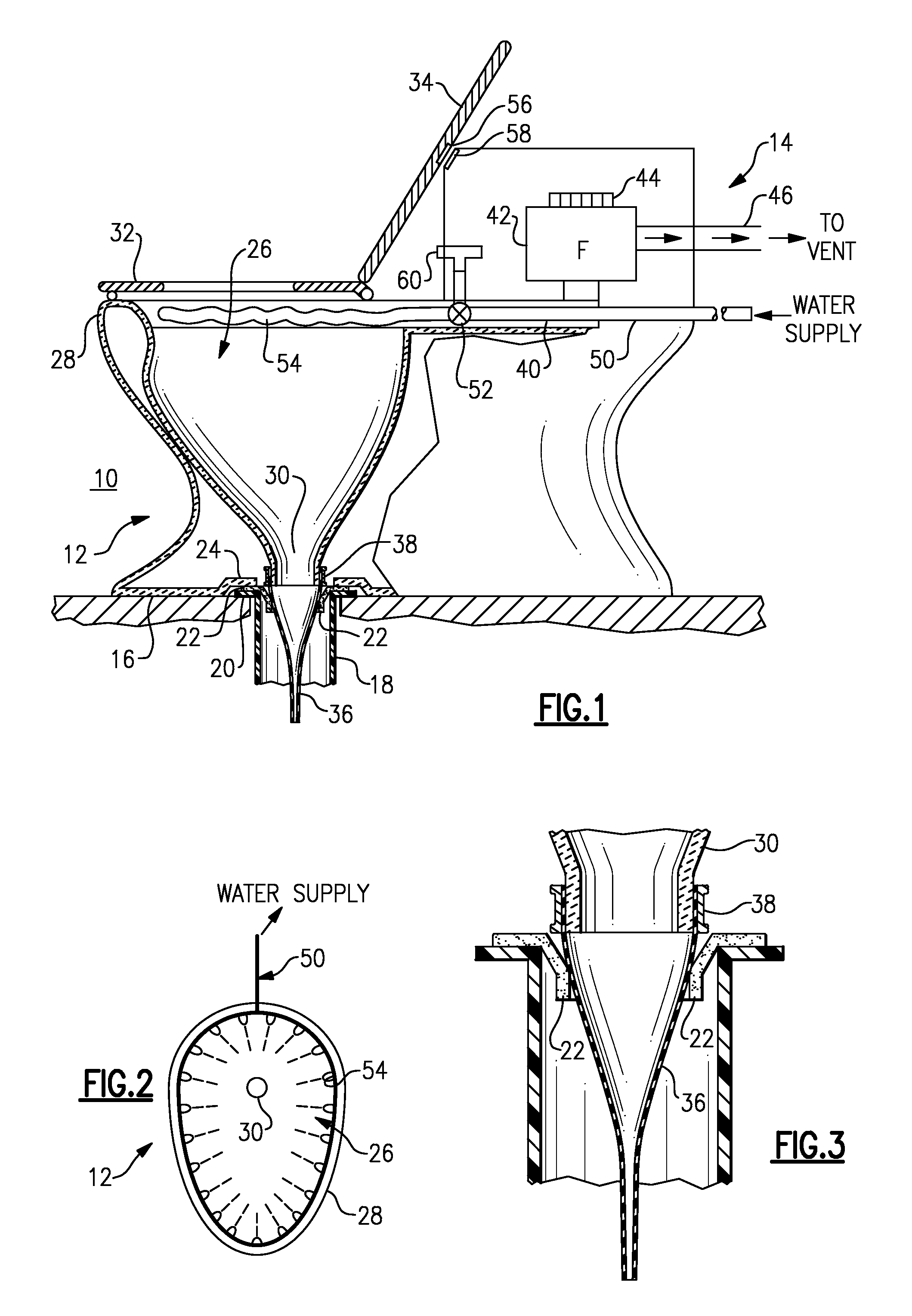

[0021]With reference to the Drawing Figures, FIG. 1, is a sectional elevation view of one exemplary embodiment of a sanitary toilet arrangement 10 in accordance with the present invention. This toilet arrangement 10 includes a bowl portion 12 and a tank portion 14 which is seated at an upper rear part of the bowl portion 12. The toilet arrangement 10 has a similar outward appearance to a traditional or standard siphon-type flush toilet, and is adapted to be mounted on the floor of a standard bathroom over the entry to the sanitary drain pipe that is located in the bathroom floor.

[0022]The bowl portion 12 has a lower side 16 that is installed against the bathroom floor. Here, FIG. 1 shows the sanitary sewer drain pipe 18, having a closet flange or closet ring 20 at its upper end, and a wax seal ring 22 installed on the closet ring 20. The bowl portion has an outlet opening 24 that mounts onto the wax seal ring 22, to contain any vapors from the sewer drain pipe 18 and prevent them fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com