Light emitting device driver circuit and method for driving light emitting device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

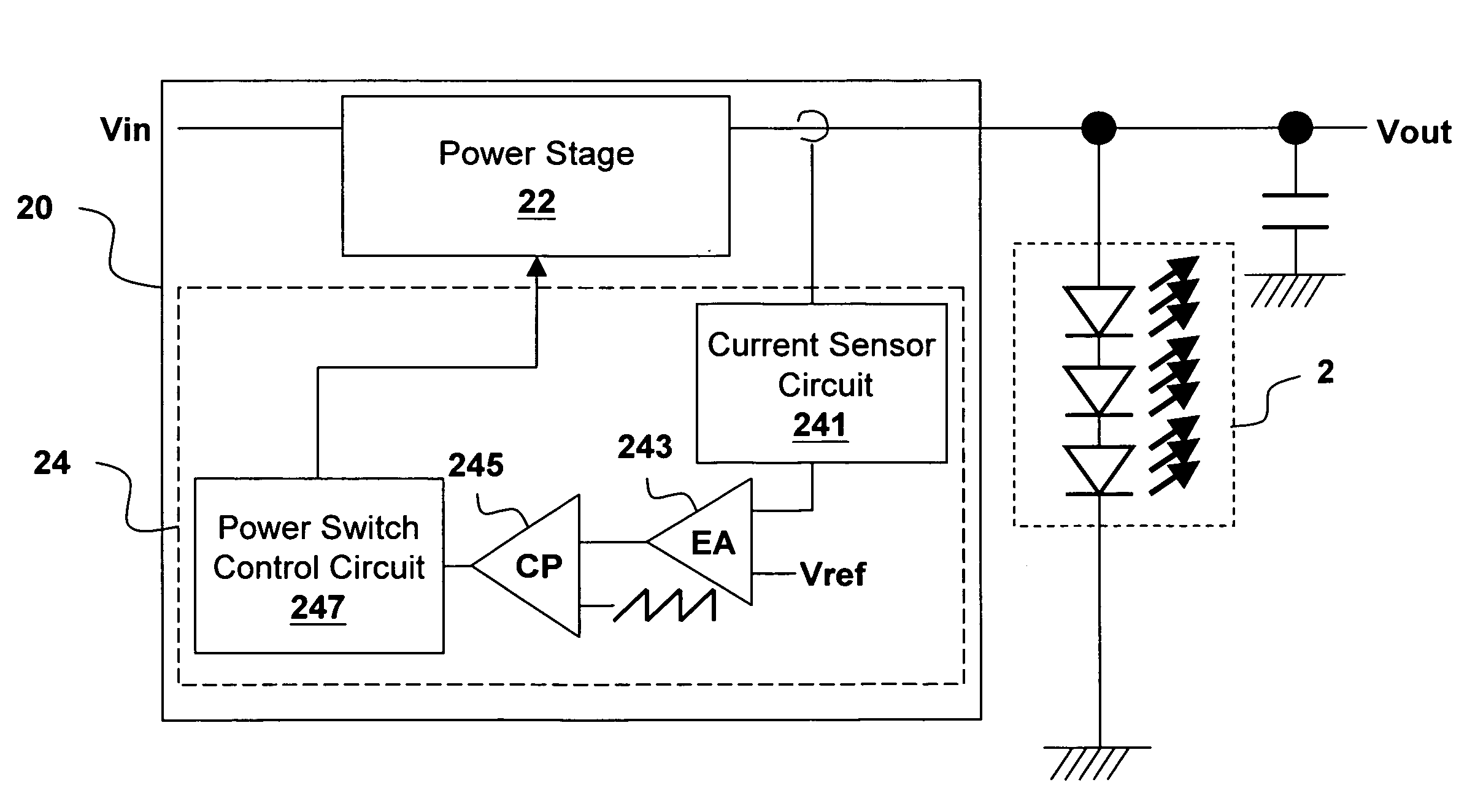

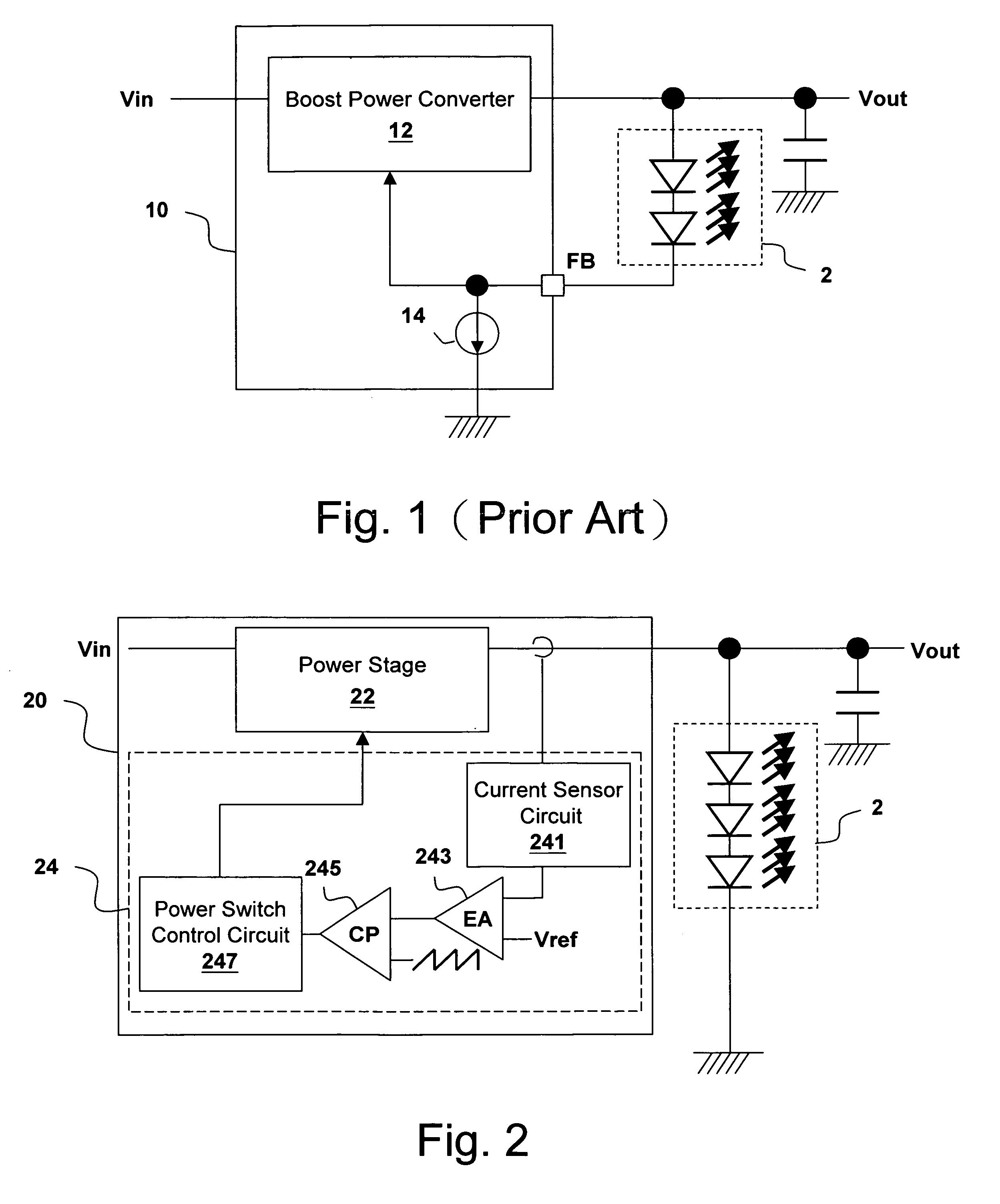

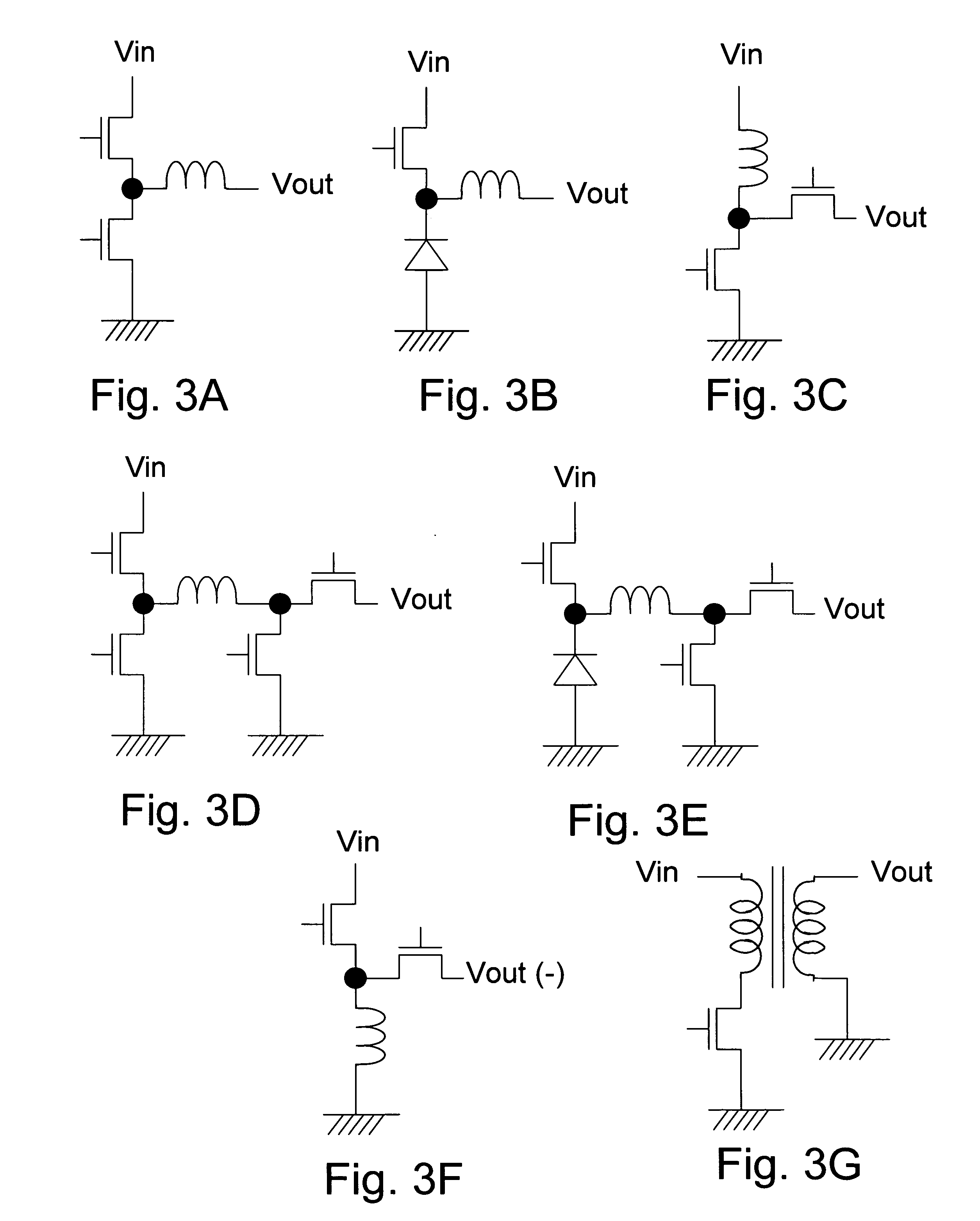

[0018]Please refer to FIG. 2, which shows an embodiment of the present invention by a schematic circuit diagram. The light emitting device driver circuit 20 of the present invention includes a power stage 22 and a control circuit 24. The control circuit 24 controls the power stage 22 to convert an input voltage Vin to an output voltage Vout, and supplies the output voltage Vout to a light emitting device 2. The number of LEDs in the light emitting device 2 can be any number as required, and the LEDs can be connected in series, in parallel, or in parallel-series; what is shown in the drawing is only an example. The power stage 22 for example can be one of: a buck power converter, a boost power converter, a buck-boost power converter, an inverter circuit, and a fly-back power converter, as shown in FIGS. 3A-3G. If the power stage 22 is an inverter circuit as shown in FIG. 3F, the LEDs in the light emitting device 2 should be connected in reverse series, as shown in FIG. 4. The present...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com