Flashlight with clip interface

a flashlight and clip technology, applied in the direction of semiconductor devices, lighting and heating apparatus, light source semiconductor devices, etc., can solve the problems of prone to leakage, wear and tear of seals, and the operation components of switches are particularly troublesome to waterproof, so as to achieve high intensity light and sufficient durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

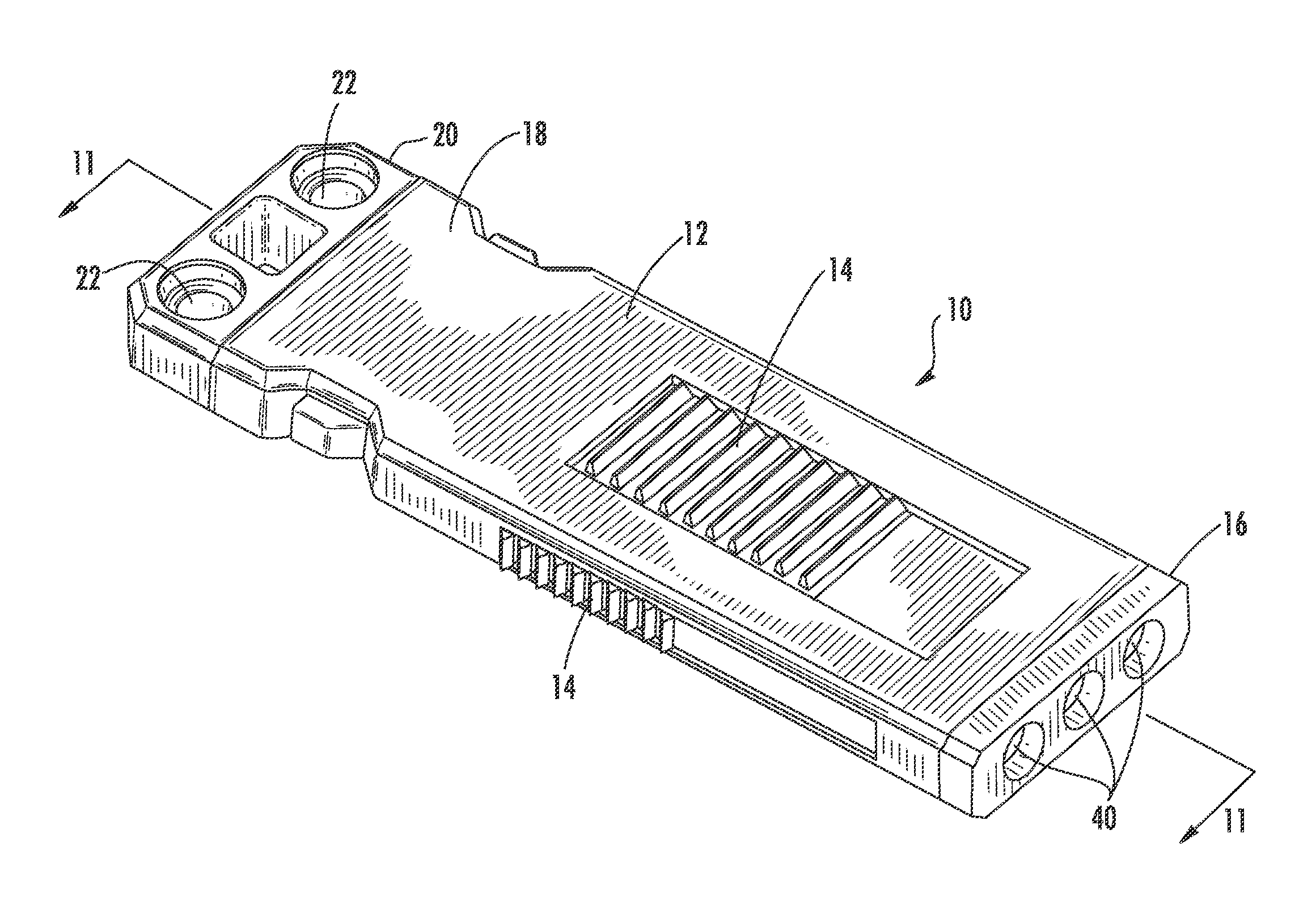

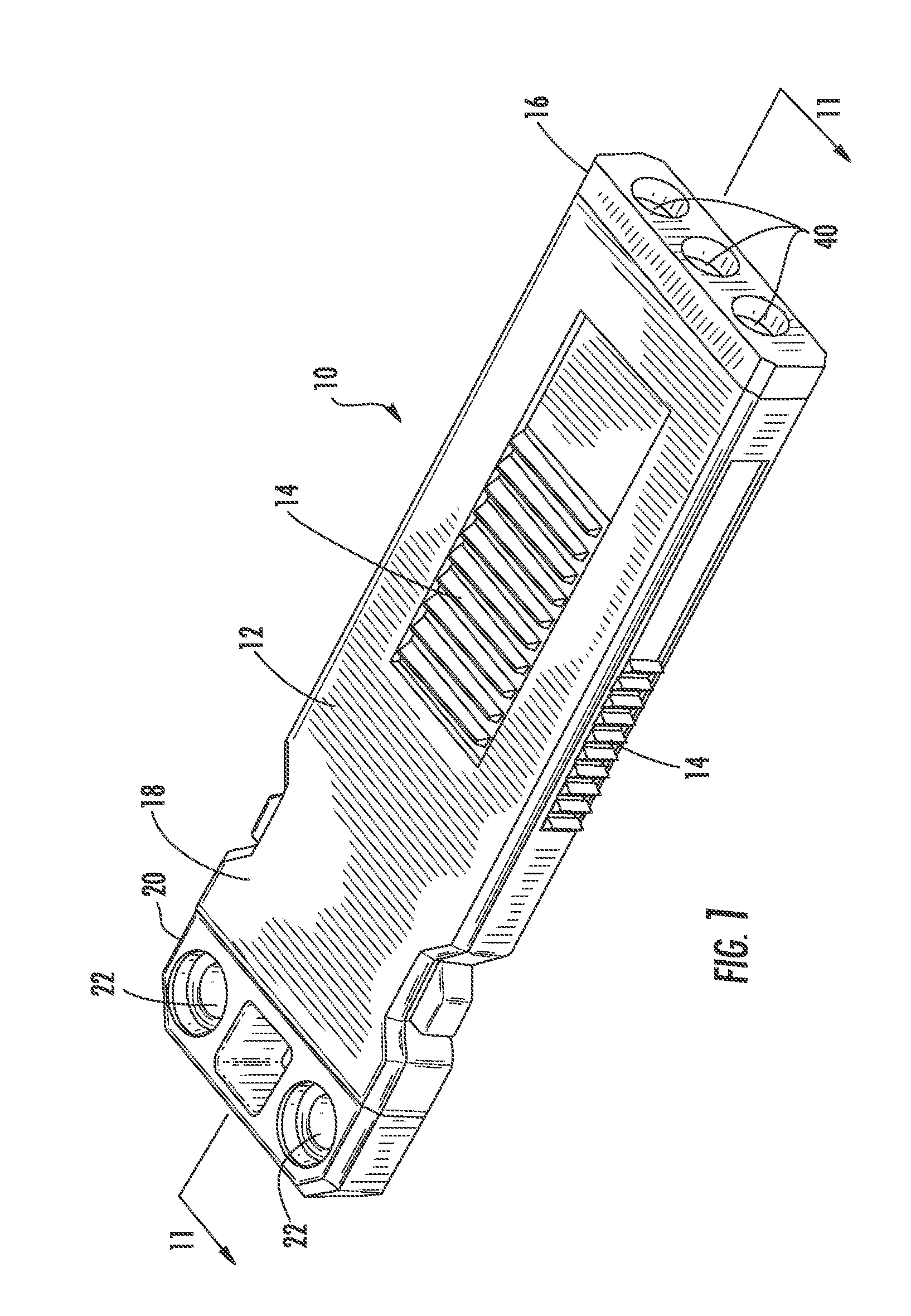

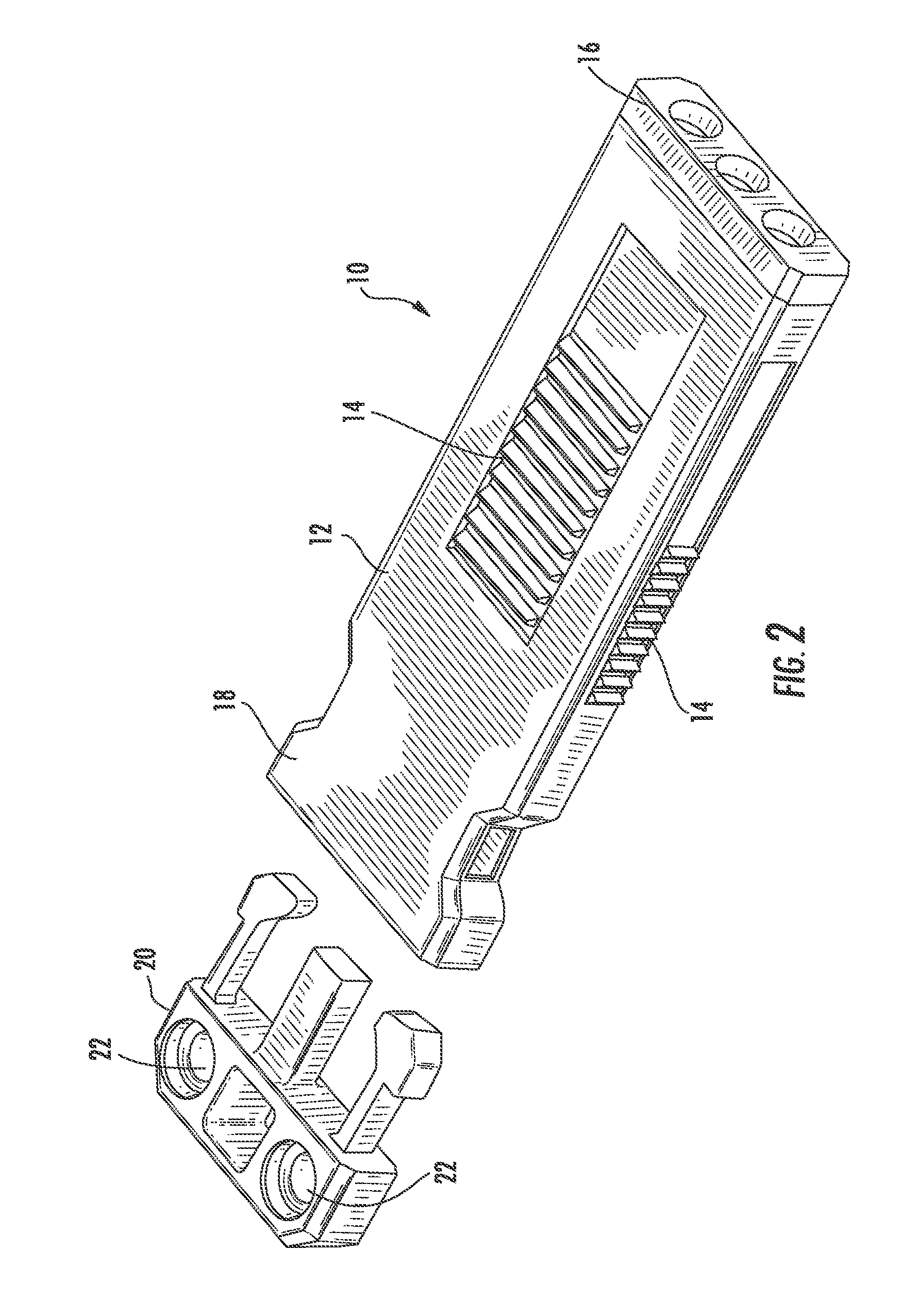

[0029]Now referring to the drawings, the lighting assembly of the present invention is shown and generally illustrated in the figures as 10. The lighting assembly 10 is the central component for the modular system described herein. The lighting assembly 10 can be seen to include an outer housing 12, at least one slide switch 14, a head assembly 16 and a modular interface 18 for receiving various modular accessories including the modular accessory mount 20 shown.

[0030]The outer housing 12 of the lighting assembly 10 of the present invention is configured in a novel manner to allow its integration into various systems and configurations. The outer housing 12 is formed to include a modular interface 18 that serves as one end of a detachable clip element. As can best be seen in FIG. 2, the modular interface 18 is shown as being formed as a female receptor end of a detachable clip assembly. Similarly, although not shown, the modular interface 18 provided on the housing 12 of the lighting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com