Container for a slush beverage

a technology for slush beverages and containers, applied in the field of containers for slush beverages, can solve the problems of structure fracturing and moving into the cavity, and achieve the effect of affecting the flexibility of product formulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

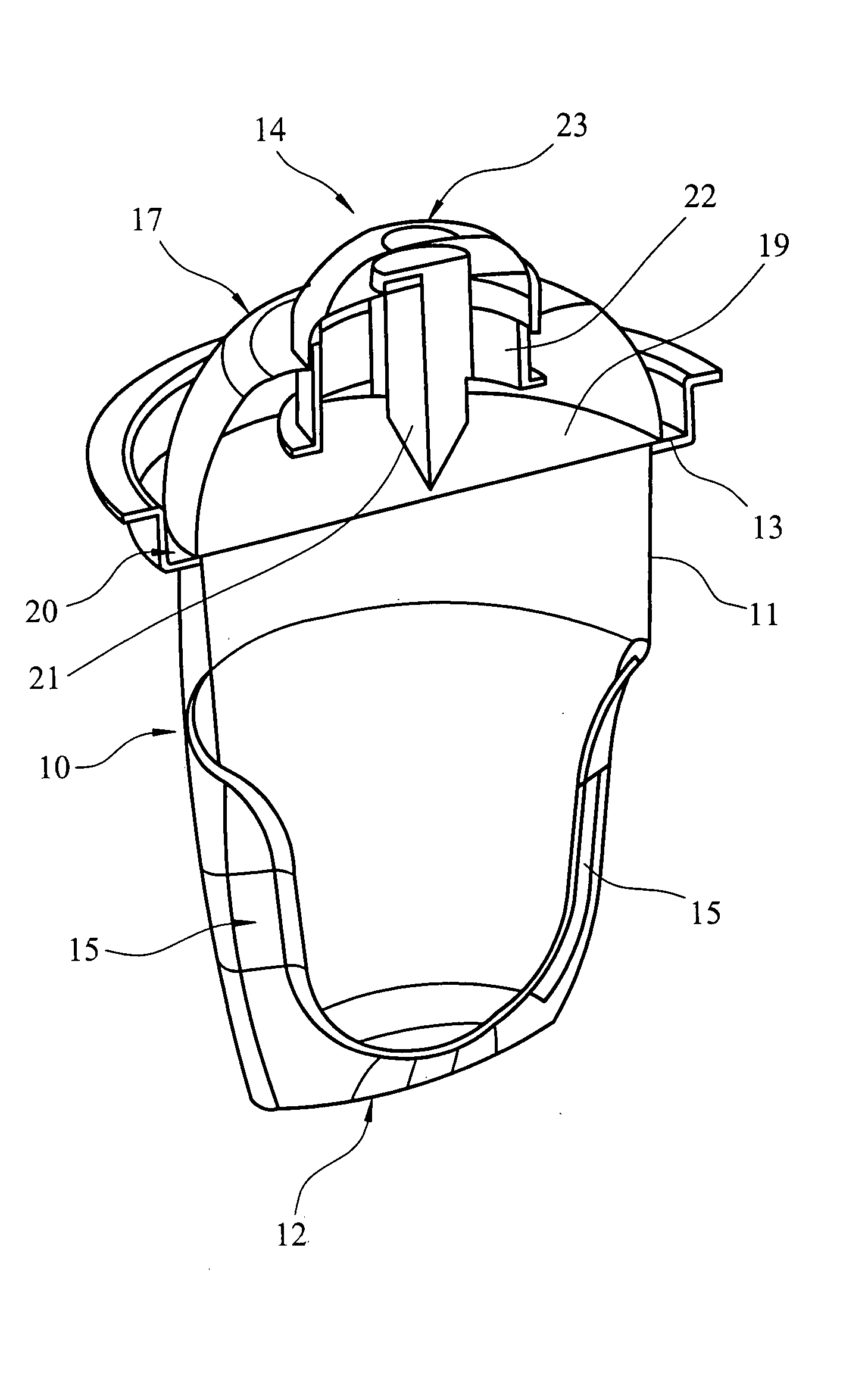

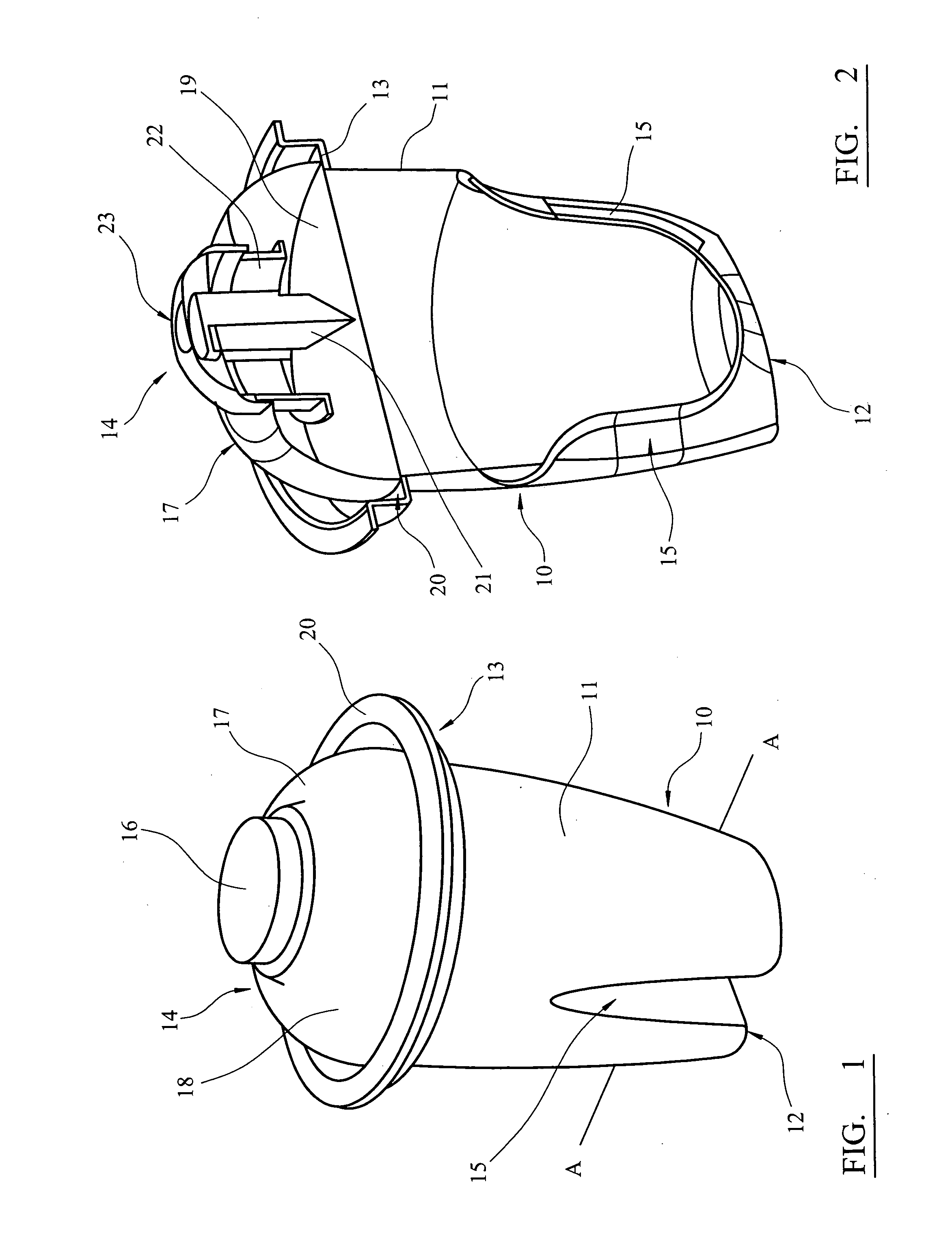

[0019]a container according to the present invention is shown by FIG. 1 wherein the container 10 is formed by a tapered side wall 11 and a base 12 upon which it may stand upright on a flat surface.

[0020]An open rim 13 of container 10 is covered by a lid means 14, the detail of which will be described with reference to FIG. 3 below. Side wall 11 includes a longitudinal indented portion 15 that provides the collapsible means of the invention. Opposing indents 15 enable the container 10 to be squeezed by a user to partially collapse and crush contents (ice) in the container. By virtue of a rigid plastic construction the collapsible means will spring back to the form illustrated.

[0021]Indents 15 also form corresponding indents in the frozen contents of the container which facilitates ice break up in use.

[0022]The section drawings (i.e. all other figures) show that the indent 15 is a single channel extending from a mid-point on one side of the container under and around the base 12 to a ...

third embodiment

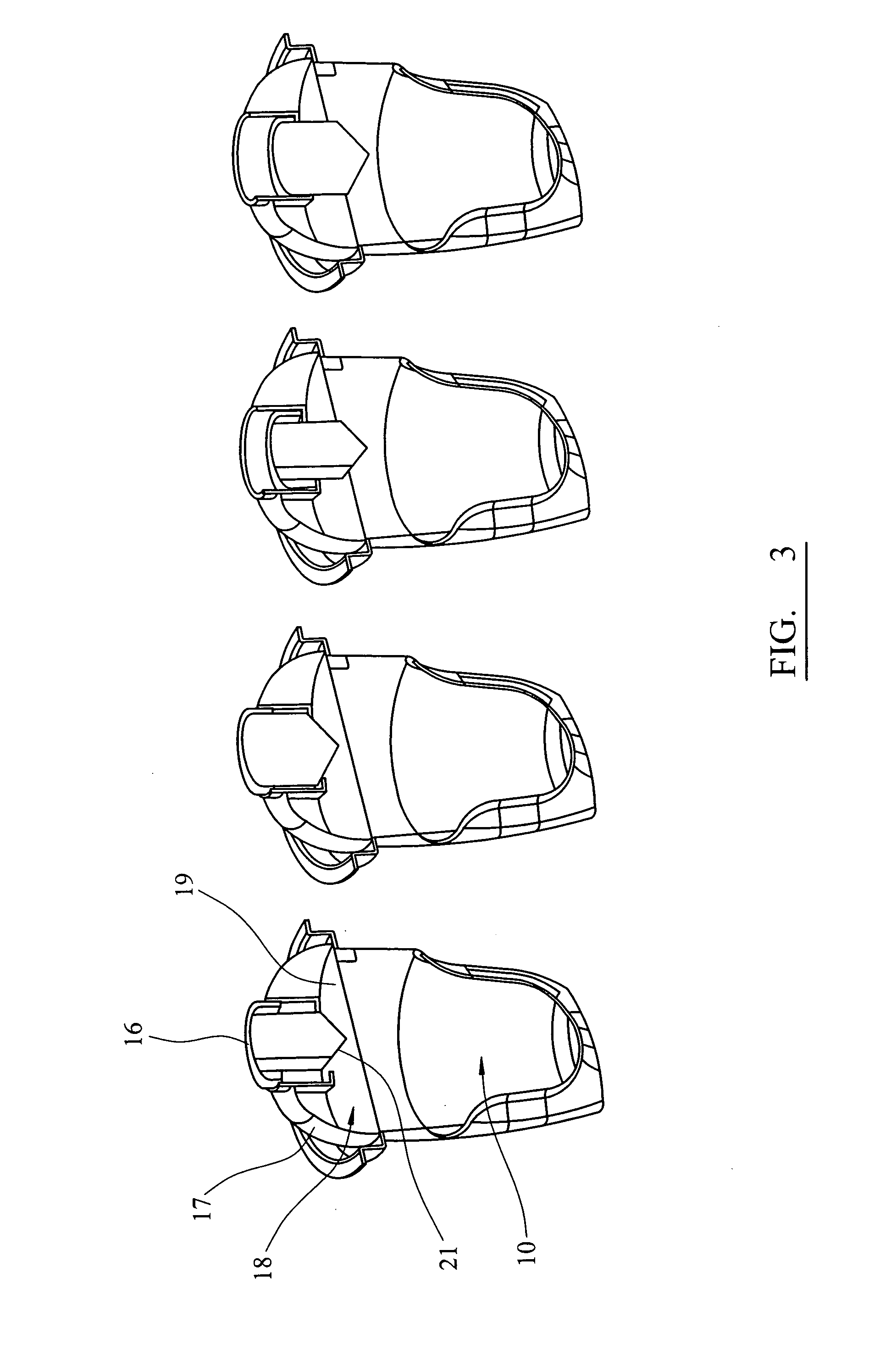

[0030]FIG. 4 illustrates a third embodiment where an alternative to the press button mechanism is employed.

[0031]Lid 14 is again formed as a dome shape 17 with a membrane seal 19 providing a compartment 18 to contain a second liquid. The rim 20 of lid 14 is initially spaced apart from rim 13 of container 10. This separation may be by virtue of a threaded engagement or bayonet type fitting, etc.

[0032]As a downward force is applied to area 23 of the dome 17 by the user, membrane 19 is brought into contact with a blade edge 24 fixed to the inside wall of the container 10 adjacent rim 13. There may be a plurality of such blades 24.

[0033]Continued pressing punctures membrane 19 and the second liquid escapes compartment 18. The lid 14 may then be twisted to make a circular cut in membrane 19 as it turns. The second liquid is then released more quickly.

[0034]In other respects the mixing process is the same; container 10 is squeezed by virtue of the collapsible means 15 and shaken.

[0035]All...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com