Two piece rail system for firearm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029]The particular values and configurations discussed in these non-limiting examples can be varied and are cited merely to illustrate at least one embodiment and are not intended to limit the scope thereof. In general, the figures are not to scale.

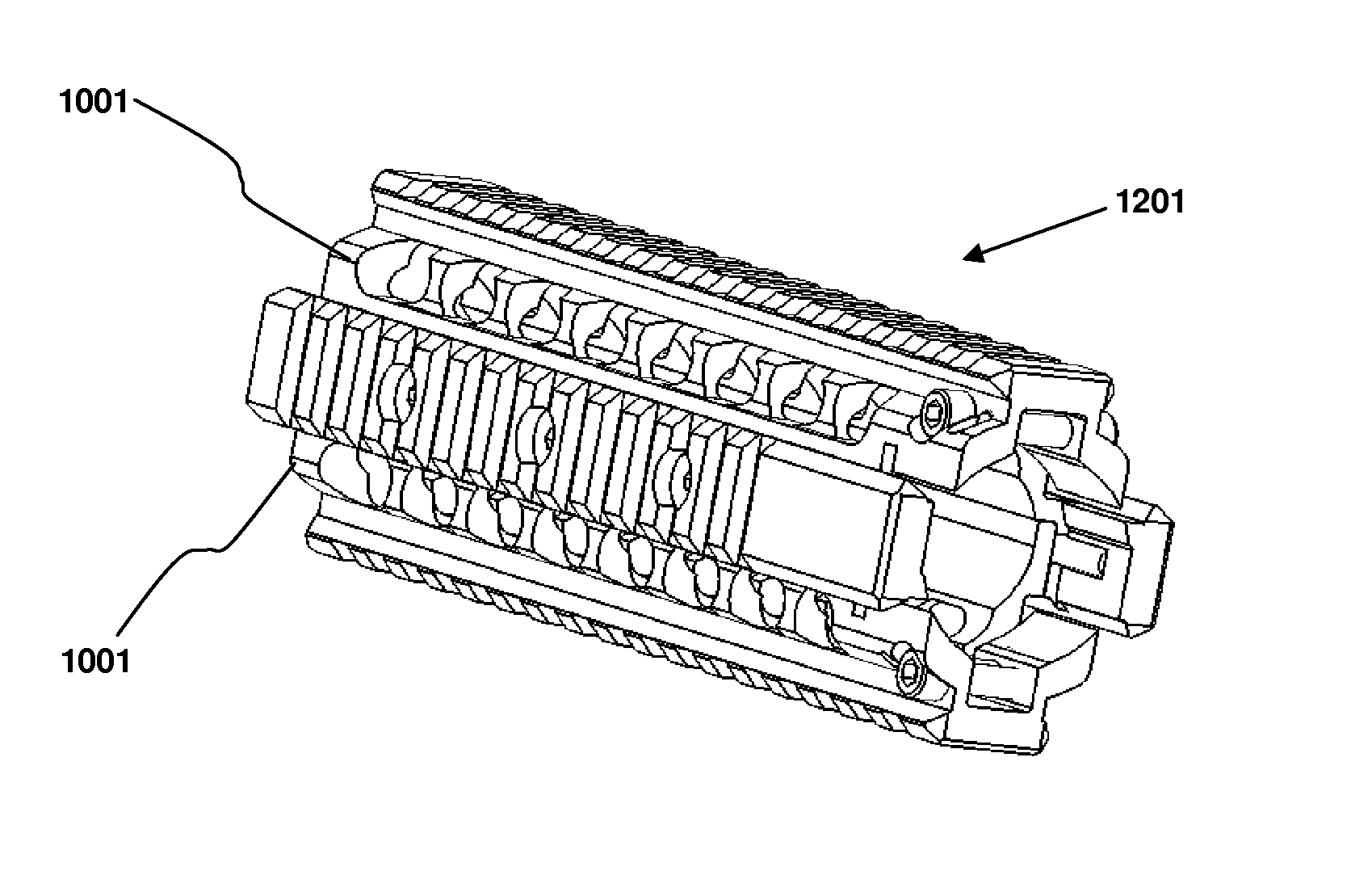

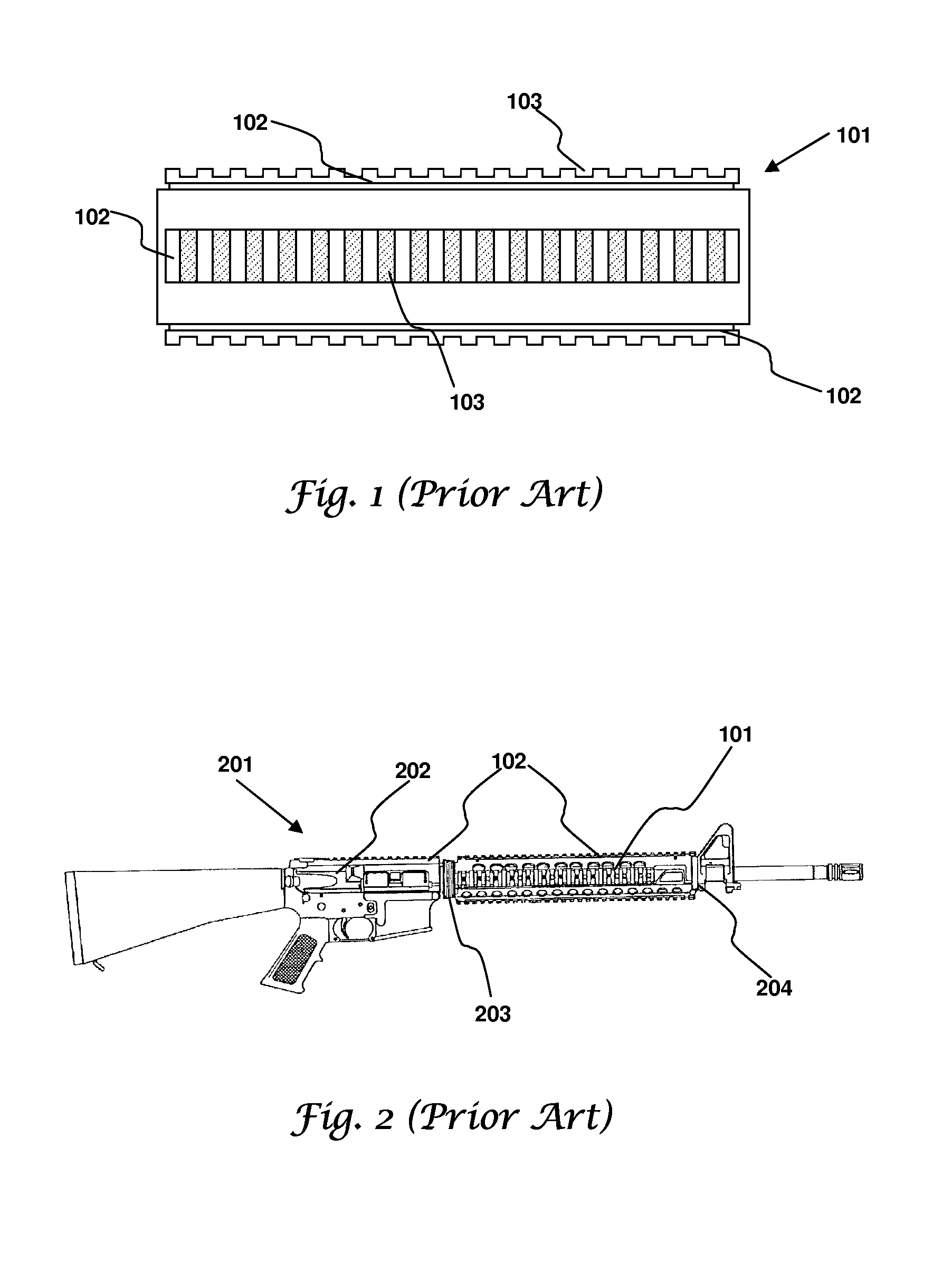

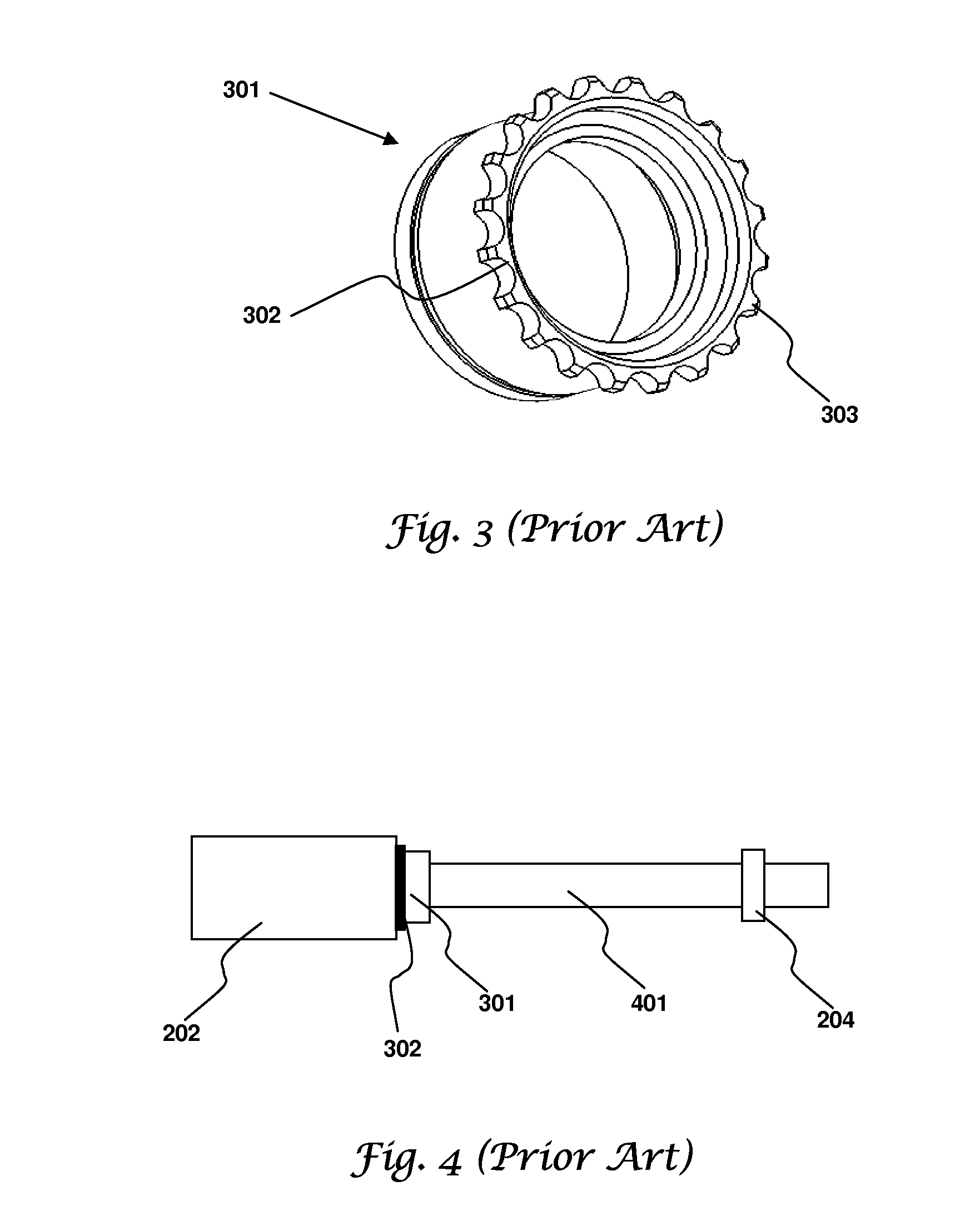

[0030]A firearm handguard having two identical halves, or half guards, can engage the barrel nut of certain firearms to thereby provide a mounting rail system. The barrel nut attaches the barrel to the receiver. The half guards can be separately positioned in engagement with the barrel nut before fastening them together. The fastening operation can cause the half guards to clamp onto the barrel nut. Alternatively, the front handguard cup of some firearms can prevent the handguard from slipping forward while the rear barrel nut engagement prevents handguard rotation. Free floating variants, however, must clamp onto the barrel nut.

[0031]FIG. 5 illustrates a quarter front view of a half guard 501 in accordance with aspects of some embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com