Non-rotational stabilization of the flame of a premixing burner

a burner and flame stabilization technology, which is applied in the direction of machines/engines, combustion types, lighting and heating apparatus, etc., can solve the problems of general undesirable combustion oscillation, combustion oscillation, damage to the entire combustion system, etc., and achieve the effect of stabilizing the burner and reliably stabilizing the combustion reaction of the spray

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038]The first exemplary embodiment of the present invention is described below with reference to FIGS. 1 to 4.

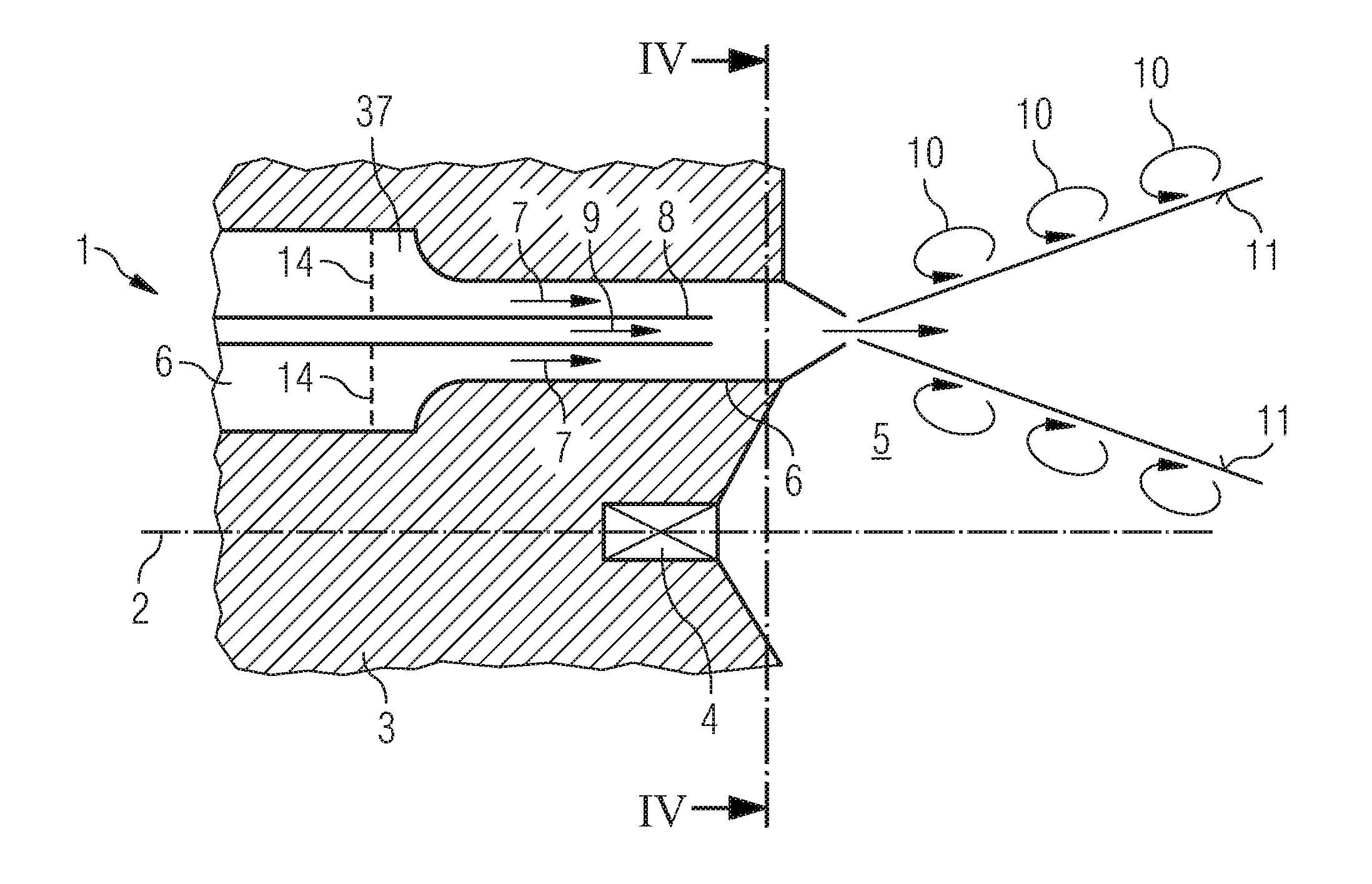

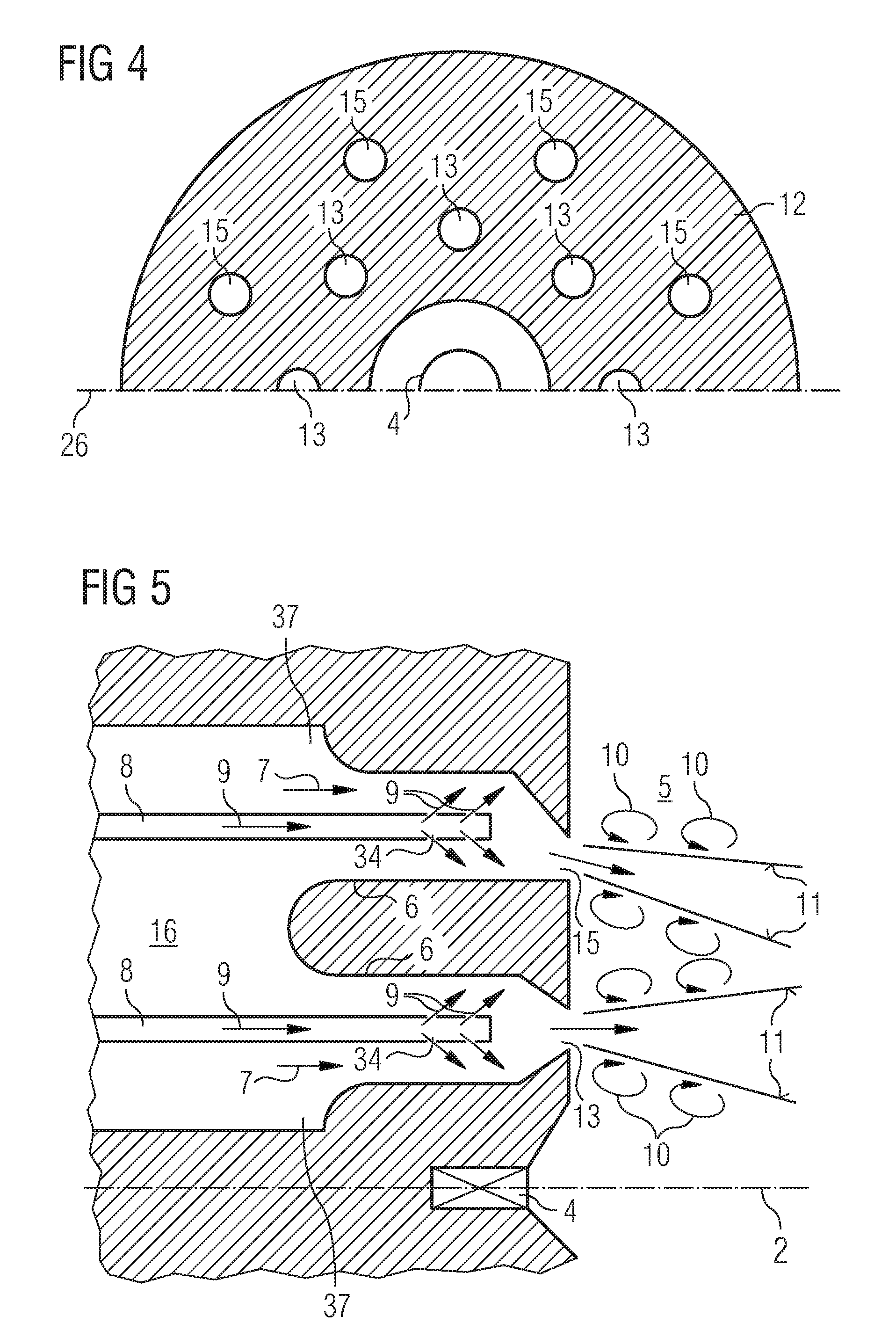

[0039]FIG. 1 shows a schematic diagram of the cross-section through a part of the rear wall of a largely rotationally symmetrical premixing burner 1. The center line 2 shows the axis of symmetry of the premixing burner 1. The premixing burner 1 comprises a housing 3, a pilot burner 4, a reaction chamber 5 and a premixing spray nozzle 6. The premixing spray nozzle 6 has an inlet opening 13, which opens into the reaction chamber 5. The pilot burner 4, which in the present exemplary embodiment is a rotationally stabilized burner, is located in the center of the rear wall of the premixing burner 1. It is concentrically surrounded by a number of premixing spray nozzles 6, which are likewise located on the rear wall of the premixing burner 1.

[0040]The premixing spray nozzle 6 contains a fuel nozzle 8, which is surrounded by an air inlet channel 37. The air inlet channel 37 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com