Apparatus and method for improving the control of a concrete screeding machine

a technology of concrete screeding machine and control apparatus, which is applied in the direction of propulsion unit arrangement, roads, constructions, etc., can solve the problems of increasing the difficulty of maneuvering forklift machines along the aisles, and the flatness or levelness errors of concrete floors become a limiting factor in the practical design, and the cost is an important factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

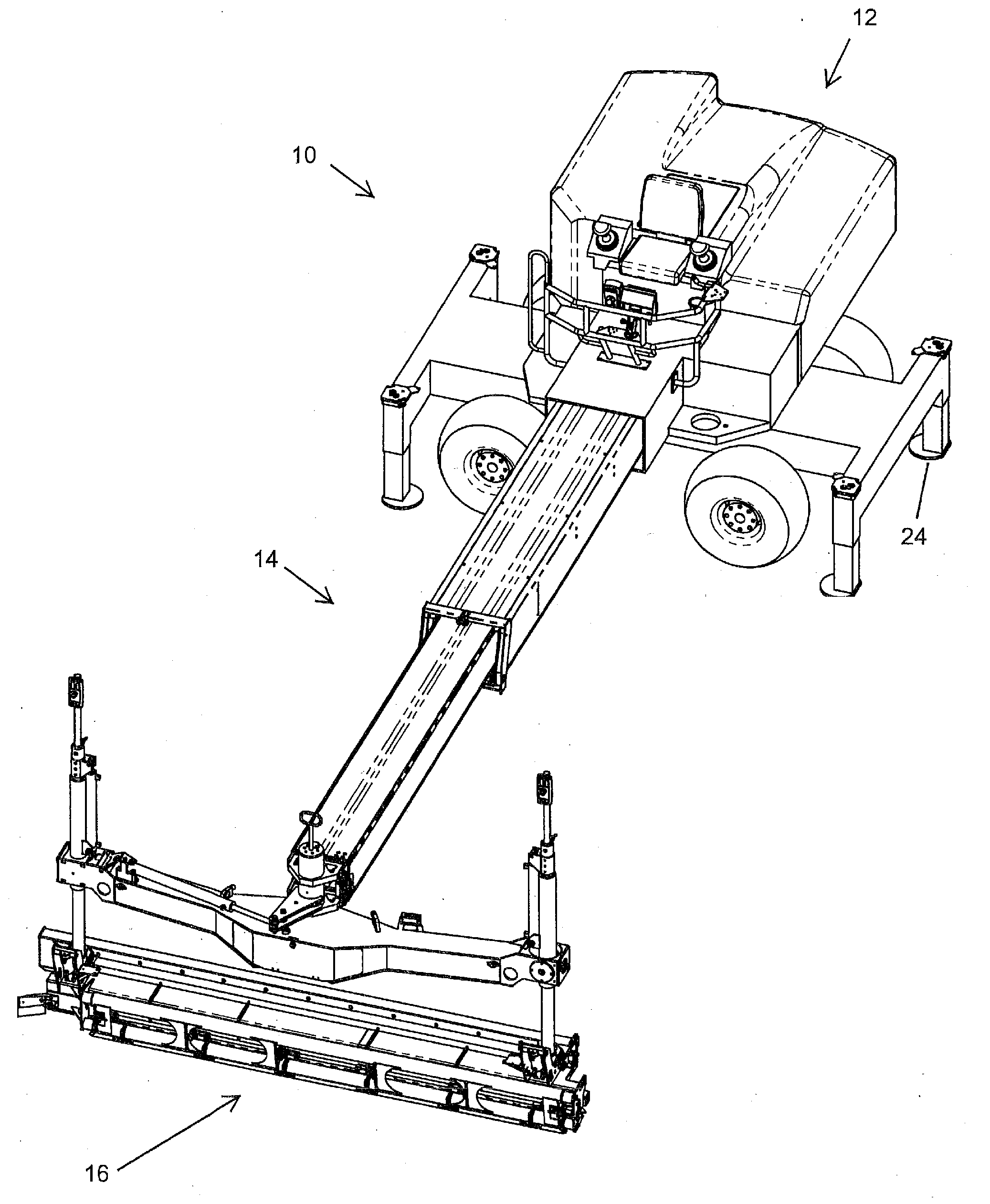

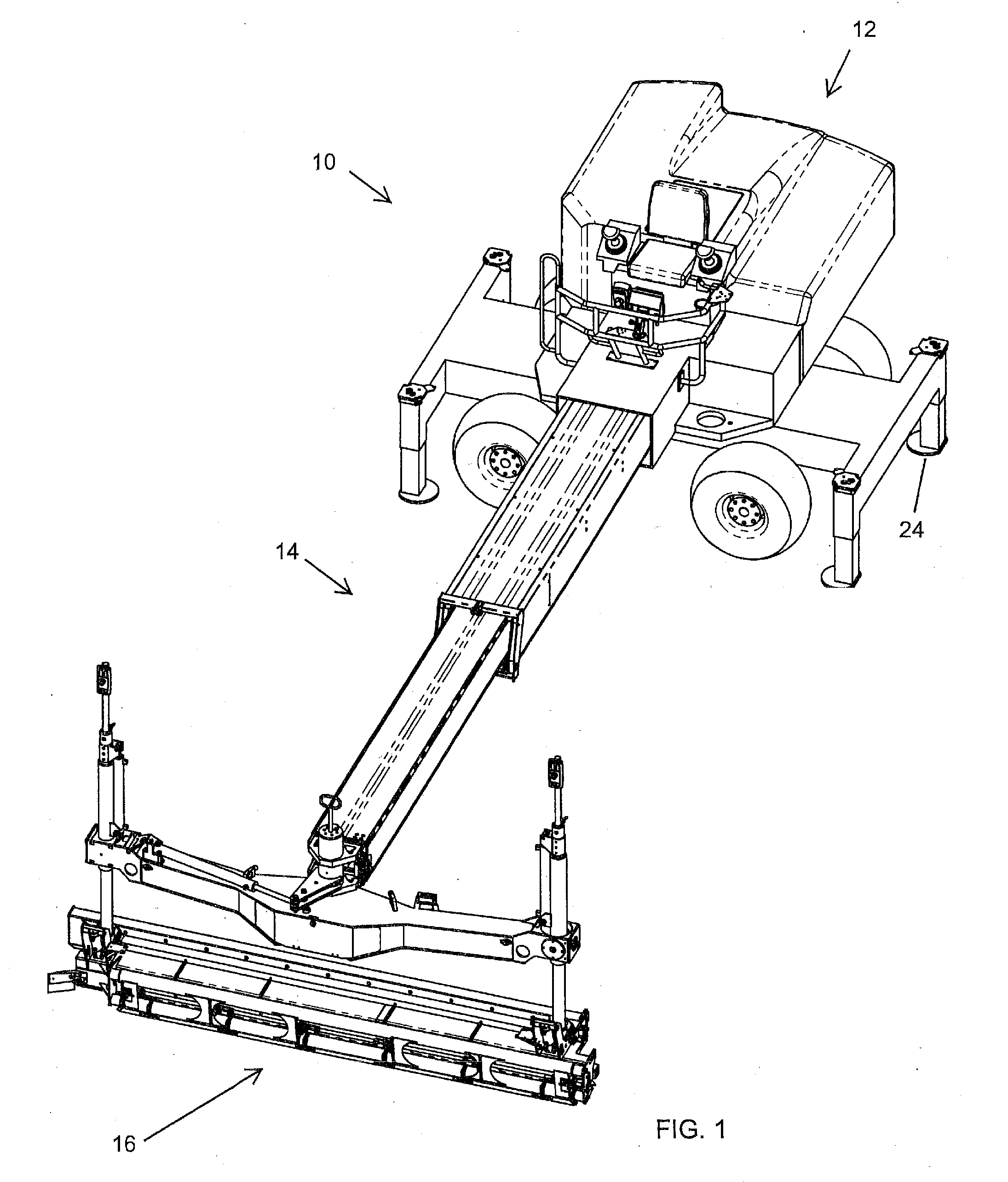

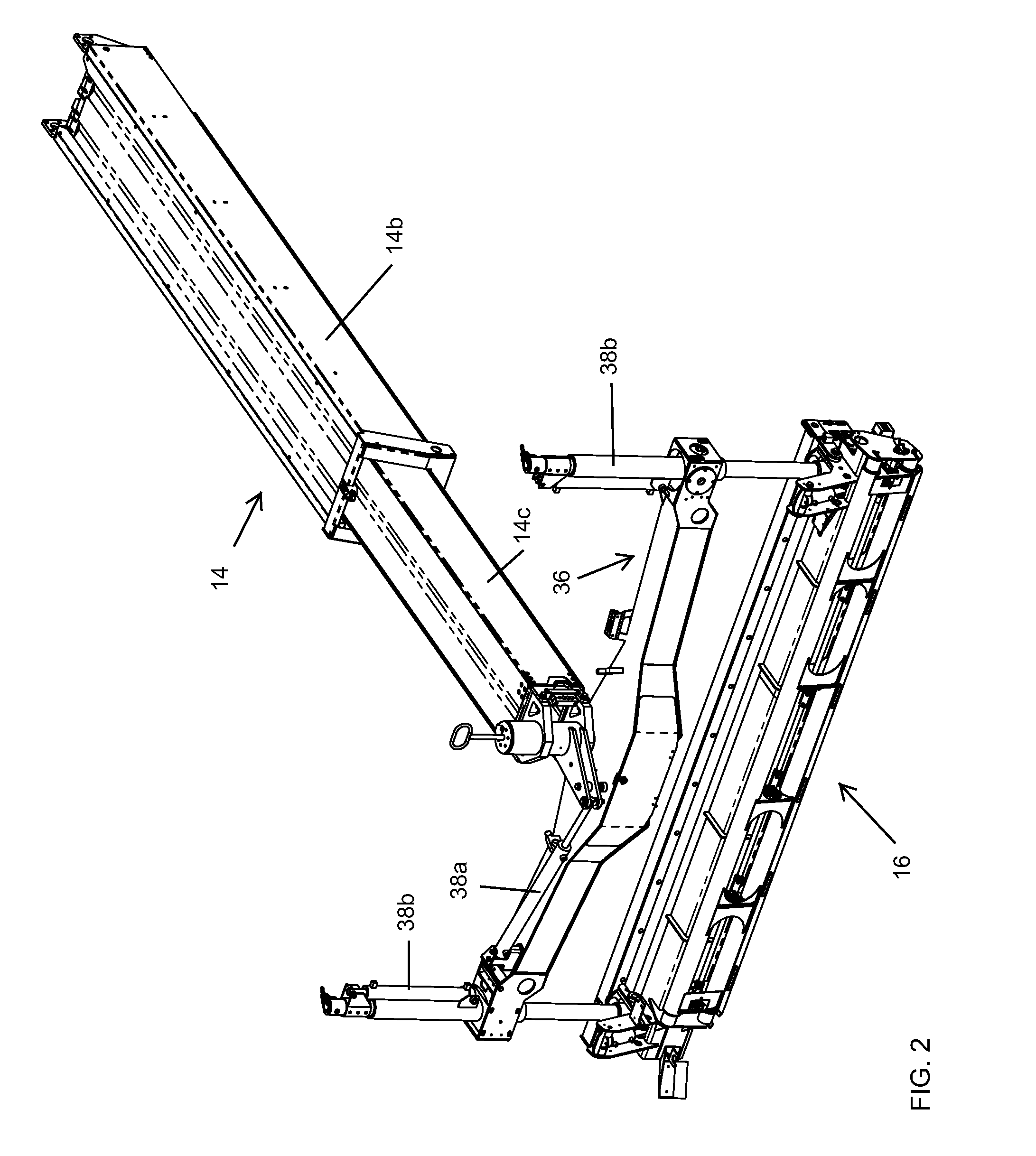

[0056]For the purposes of illustration and disclosure of the aspects of the present invention, a Somero SXP-D LASER SCREED™ screeding machine will be used as the example. However, clearly this example is not intended to limit the scope of the present application and clearly aspects of the present invention are suitable for use on other types of screeding machines.

[0057]A typical wide-placement concrete pour might consist of a set of eight to sixteen screeding passes from left to right before another row is started. This number of consecutive passes can typically complete the full-width of a typical wide-placement concrete pour. During each screeding pass made by a LASER SCREED™ screeding machine (or other suitable screeding machine or device) and its respective human operator, a number of human factor variables can come into play that can often affect the level of quality achieved in the final concrete surface. For instance, the travel speed of the screed head as it travels over the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com