Sheet-like article and method for making the same

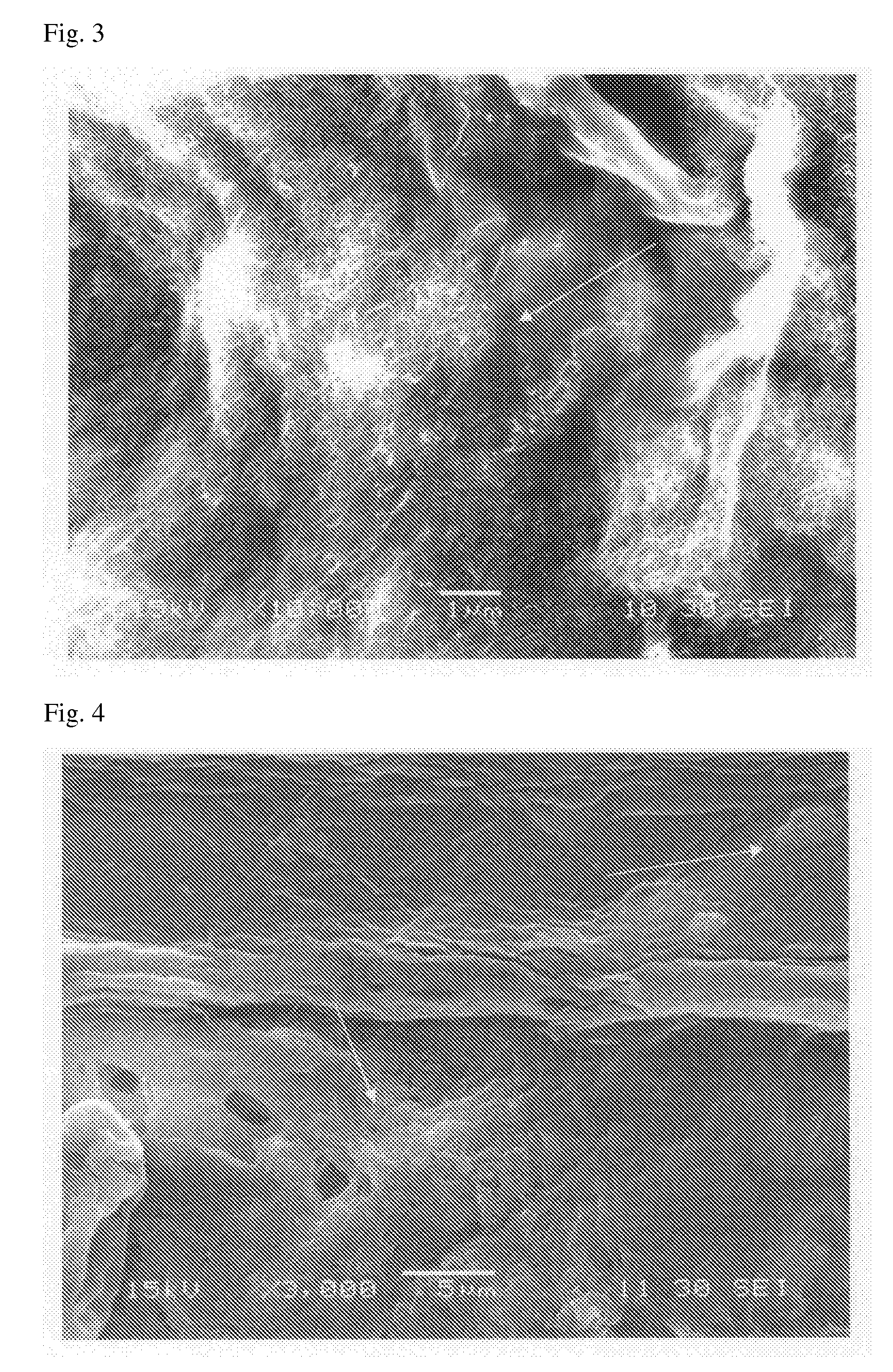

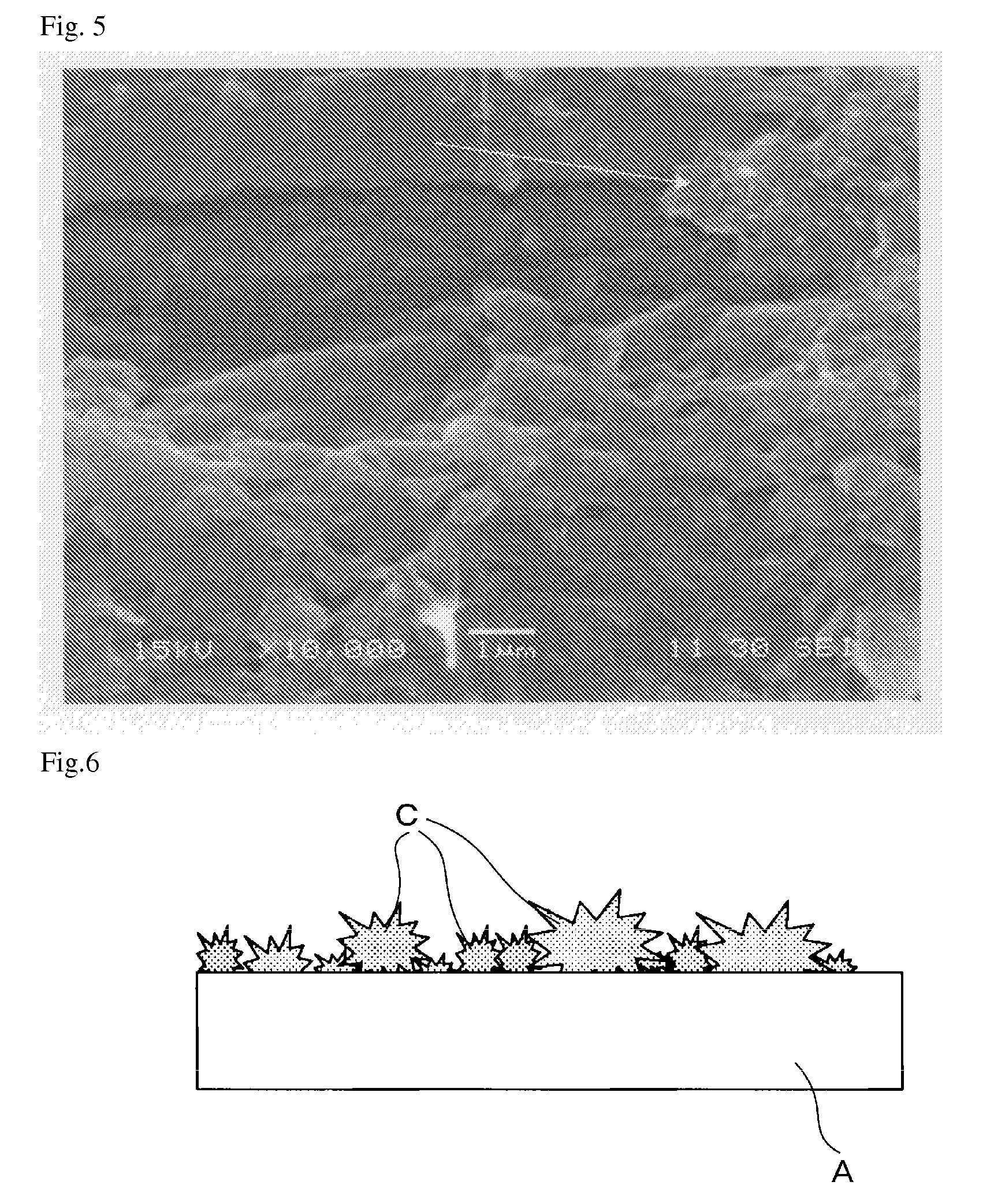

a technology of sheet paper and paper, applied in the field of sheet paper, can solve the problems of difficult to obtain the full performance of carbon fiber, difficult to achieve the best performance characteristics of carbon fiber, and agglomeration of carbon fiber, and achieve the effect of good dispersibility in water, dense and uniform network structur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0057]Fifty percent by mass of hardwood bleached kraft pulp and 50 mass % of softwood bleached kraft pulp were dispersed in water and beaten in a double disc refiner to prepare a pulp slurry having a CSF freeness of 350 ml. Cationic starch (Neotack L-1, from Nihon Syokuhin Kako Co., Ltd.) was mixed therein in an amount of 2 mass % relative to the pulp mass. The CNT dispersion of anionic surfactant type prepared by the dispersing method 1 was then mixed therein to give a slurry having a CNT solid content of 5 mass % relative to the pulp mass. The slurry was converted into a sheet-like article having a grammage of 100 g / m2 by a wet papermaking process using a wire cloth.

example 2

[0058]A sheet-like article having a grammage of 100 g / m2 was made in the same manner as in Example 1, except for replacing the CNT dispersion of anionic surfactant type obtained by the dispersing method 1 with the CNT dispersion of cationic surfactant type obtained by the dispersing method 2 and using 3 mass % of carboxymethyl cellulose in place of the cationic starch.

example 3

[0059]A sheet-like article having a grammage of 100 g / m2 was made in the same manner as in Example 1, except for replacing the CNT dispersion of anionic surfactant type obtained by the dispersing method 1 with the CNT dispersion of physical treatment type obtained by the dispersing method 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dispersion potential | aaaaa | aaaaa |

| Polarity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com