Production of metal products directly from underground ore deposits

a technology of underground ore and production of metal products, which is applied in the direction of lithium compounds, dissolving, and well accessories, etc., can solve the problems of limited ore deposits, large and expensive draglines or other excavating, and the inability to reach ore deposits underground. , to achieve the effect of increasing the range to which water is applied and increasing the range of removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

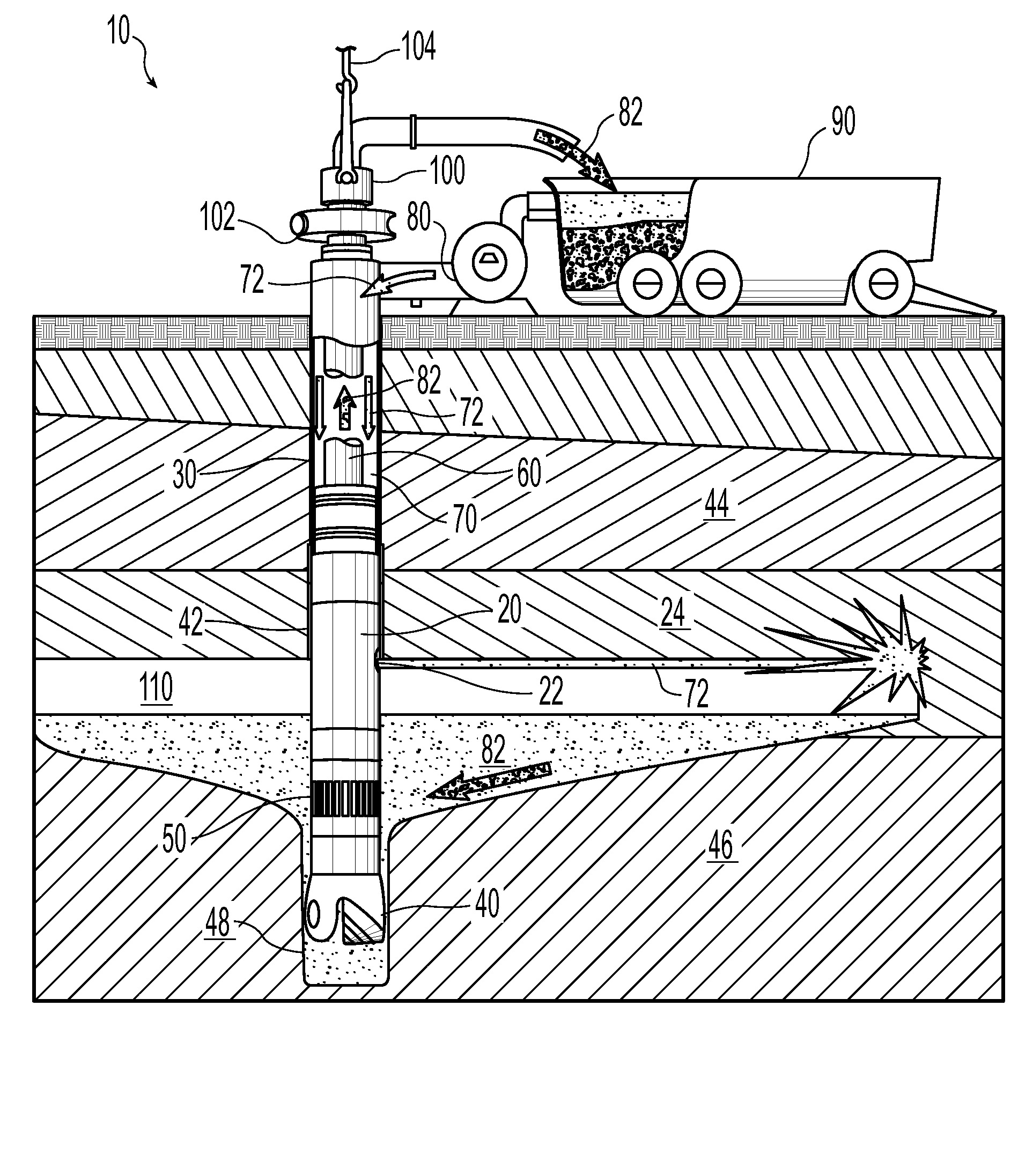

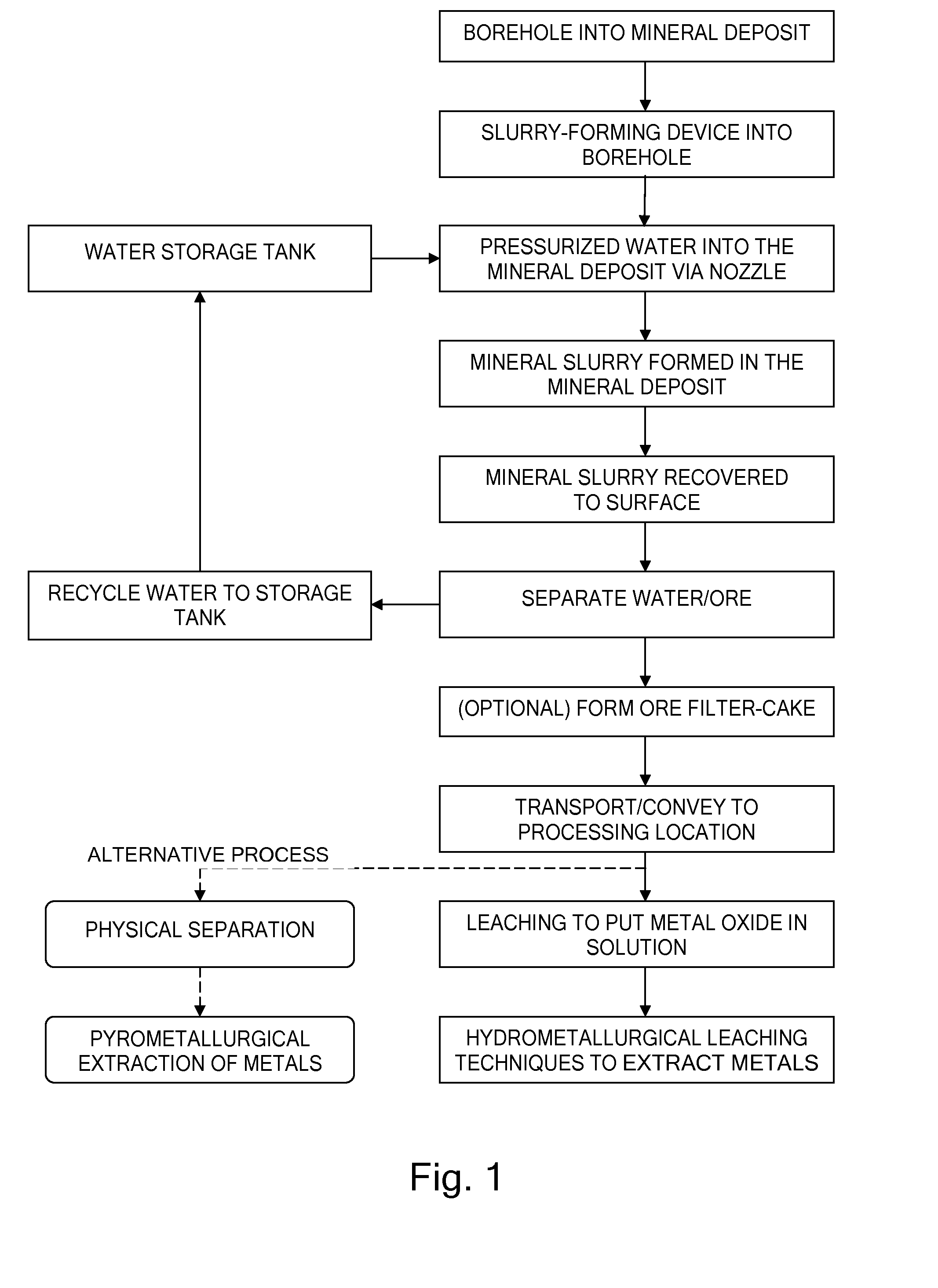

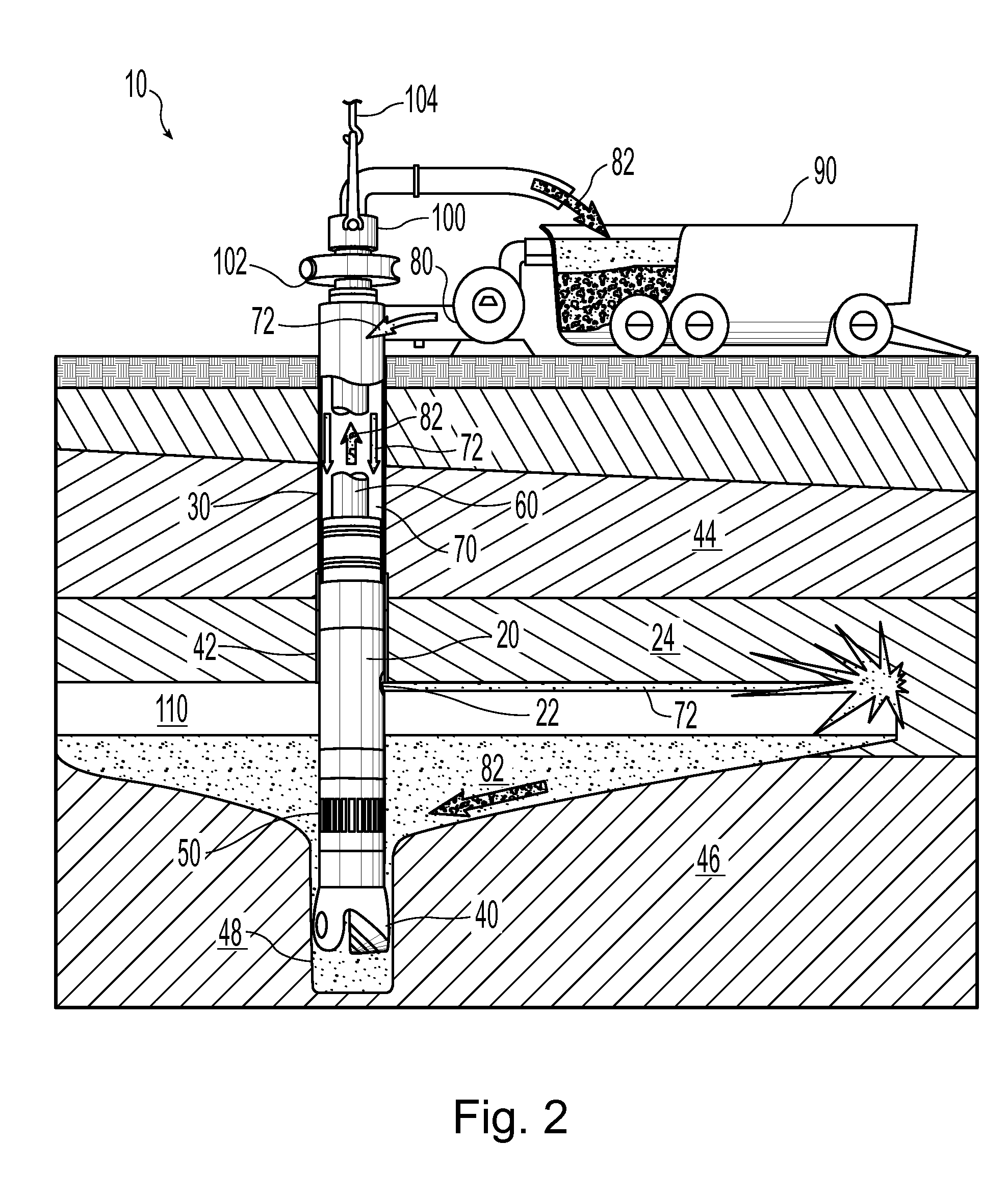

[0037]Referring now to FIG. 1, a method is disclosed for producing metals and metal compounds that may be used to extract metal products from environmentally sensitive areas. As shown in FIG. 1, the method may include steps of:[0038](a) forming a borehole at an accessible site into a mineral deposit, the mineral deposit containing metal oxides such as metal oxides of manganese;[0039](b) inserting a slurry-forming device having a nozzle into the borehole, the device adapted to directing pressurized water through the nozzle into the mineral deposit;[0040](c) supplying pressured water through the nozzle into the mineral deposit;[0041](d) forming a mineral slurry containing metal oxides, such as metal oxides of manganese;[0042](e) extracting the mineral slurry through the borehole to the surface;[0043](f) optionally, separating water from the extracted mineral slurry, which may be recycled to a water storage tank;[0044](g) optionally, forming a filter-cake of the mineral slurry having a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Acidity | aaaaa | aaaaa |

| Mesh size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com