Corrugated Micro Tube Heat Exchanger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021]The present invention enables the exchange of energy from one fluid to another in a heat exchanger without a significant reduction in pressure across the core while offering high heat transfer to weight ratio and reduced volume of the core. It does so by employing a device and / or methodology which is cost-effective and offers a relative ease of manufacture.

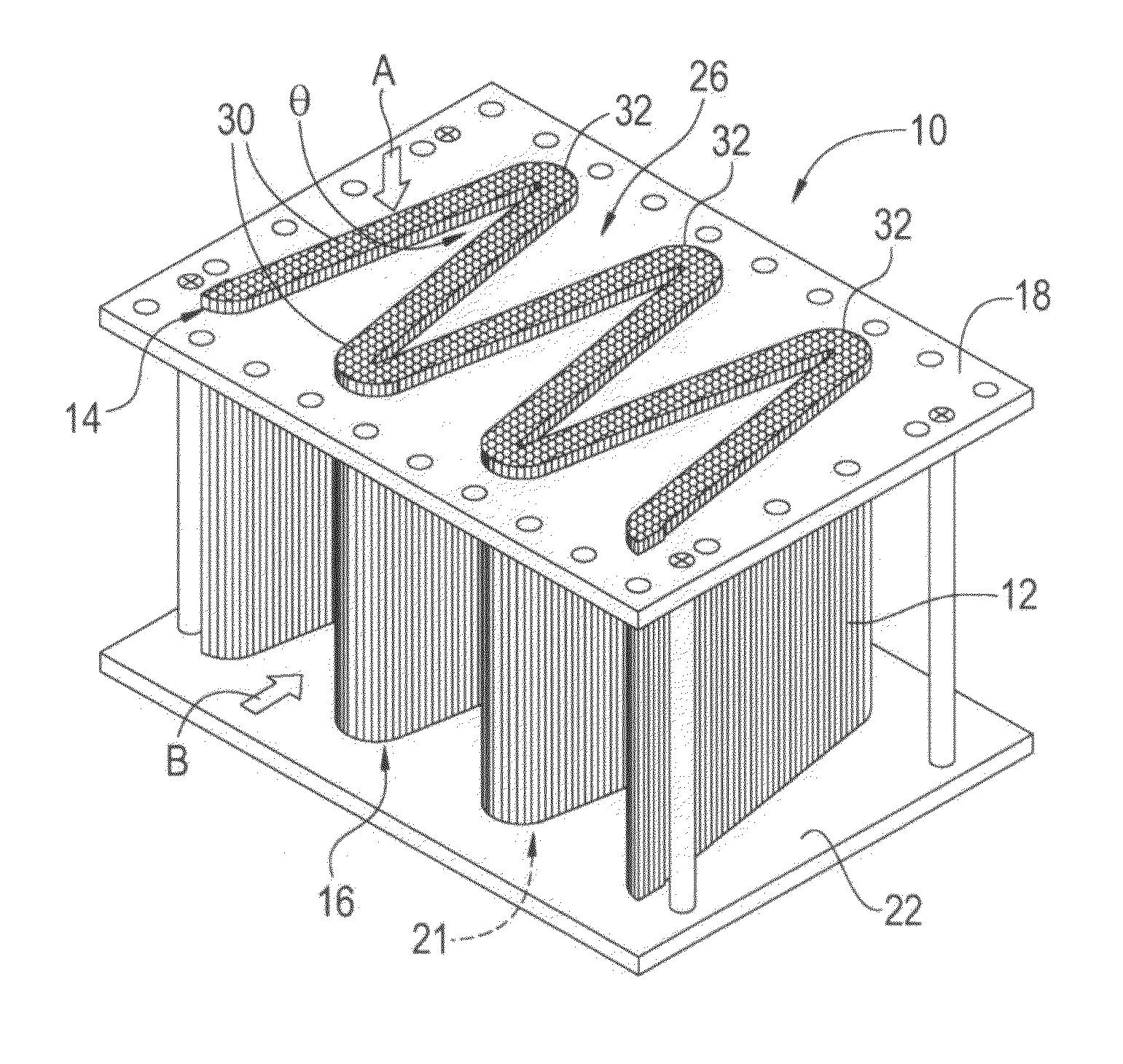

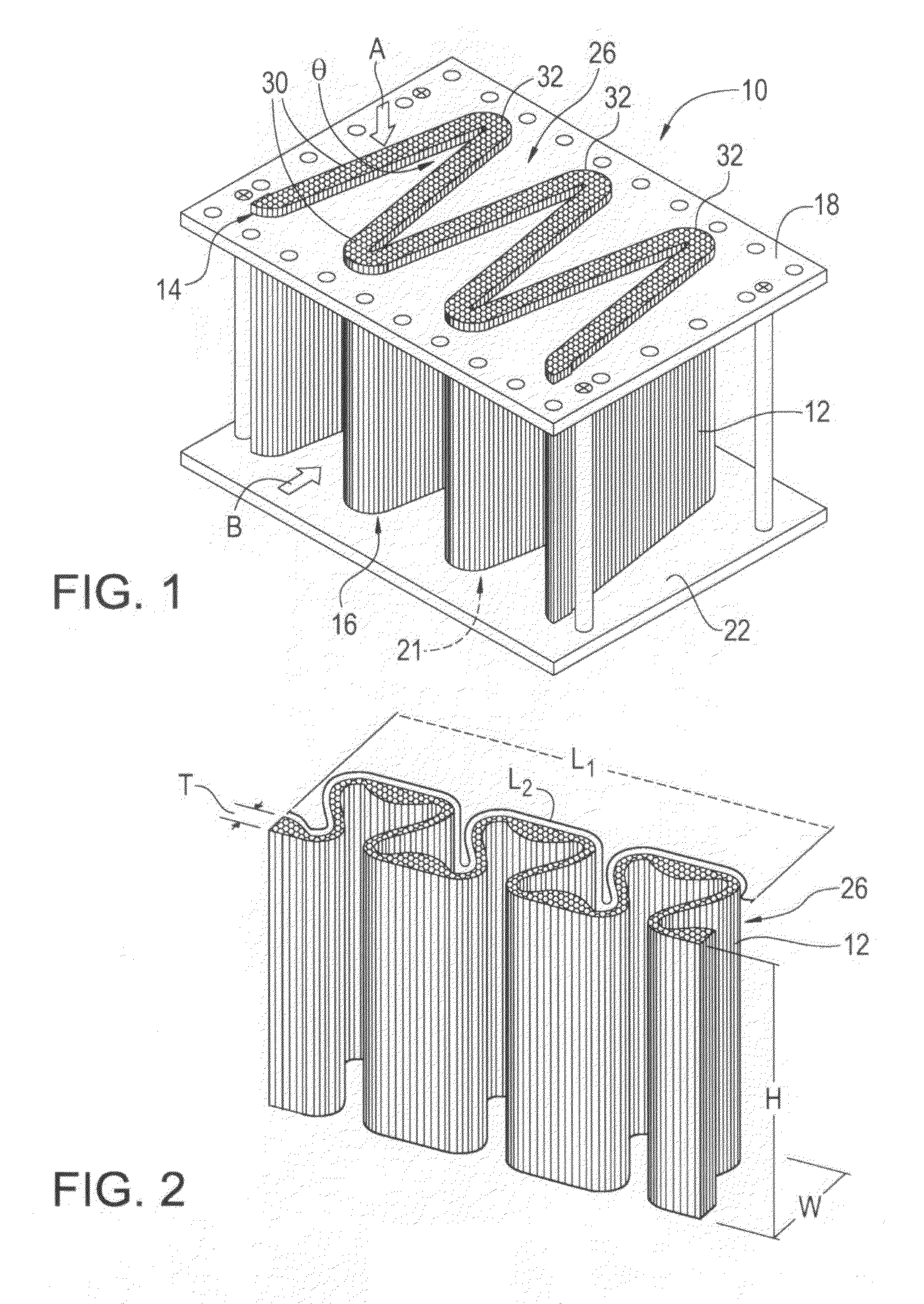

[0022]Referring now descriptively to the drawings, the attached figures illustrate one particular embodiment of the invention, in which a heat exchanger device 10 comprises corrugated micro tubes 12. As seen in FIG. 1, the illustrated embodiment has a plurality of substantially parallel tubes 12 in fluid communication with a first manifold 18 and a second manifold 22. Each parallel tube 12 has an outer diameter D (see FIG. 5) of less than or equal to one millimeter and further comprises a first end portion 14 and a second end portion 16.

[0023]First manifold 18 forms an inlet (not shown) for the first fluid A. First manifold ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com