Drum winch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

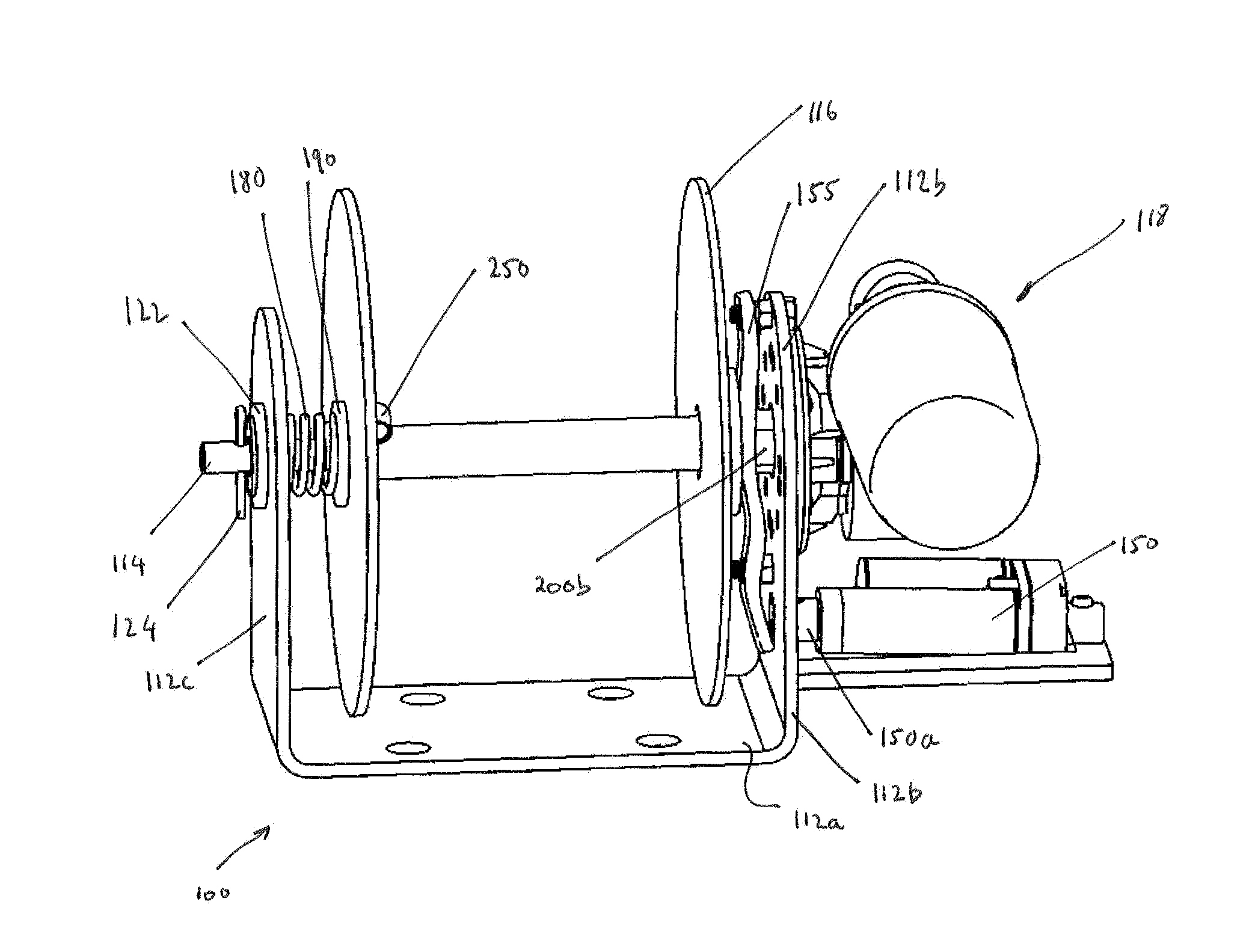

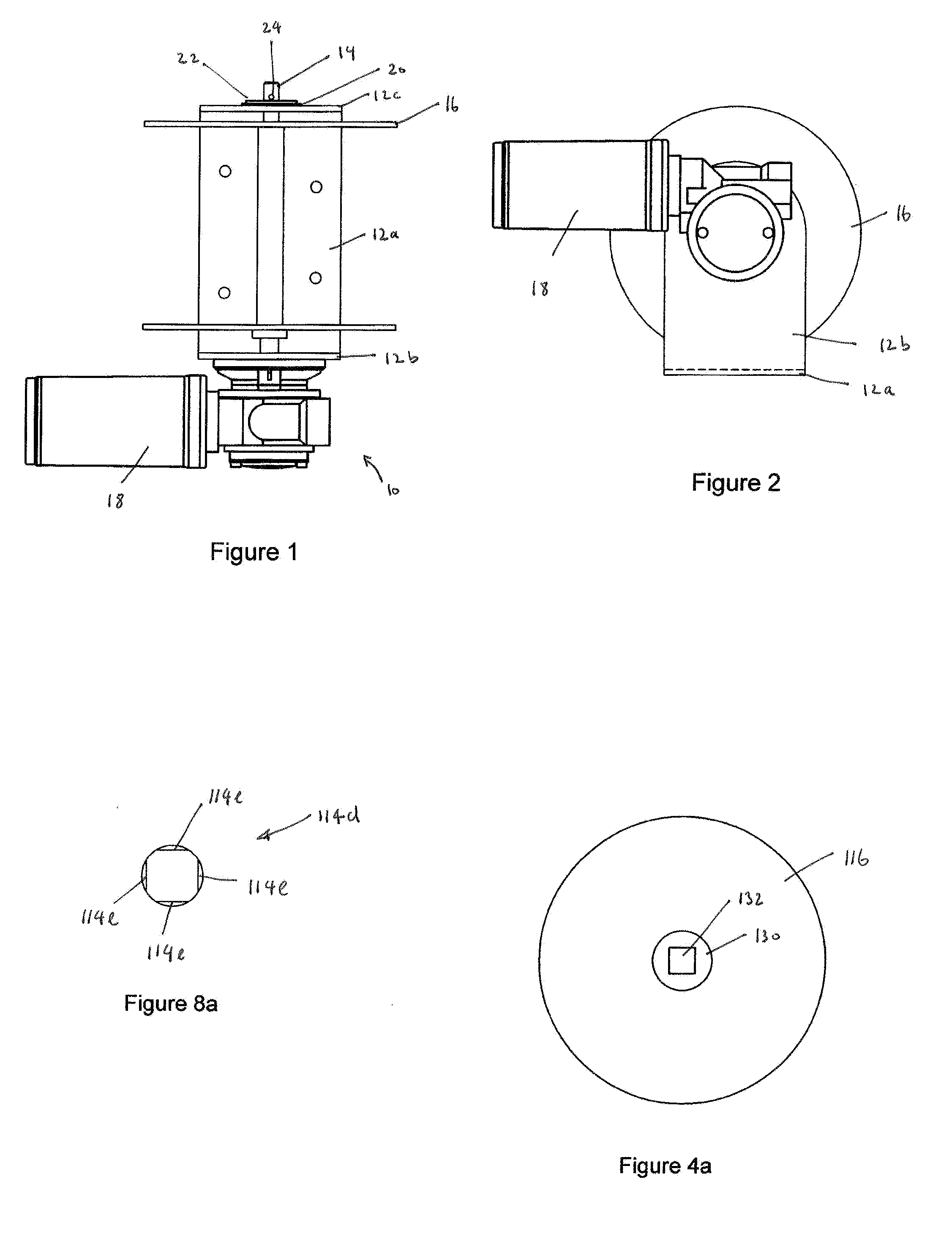

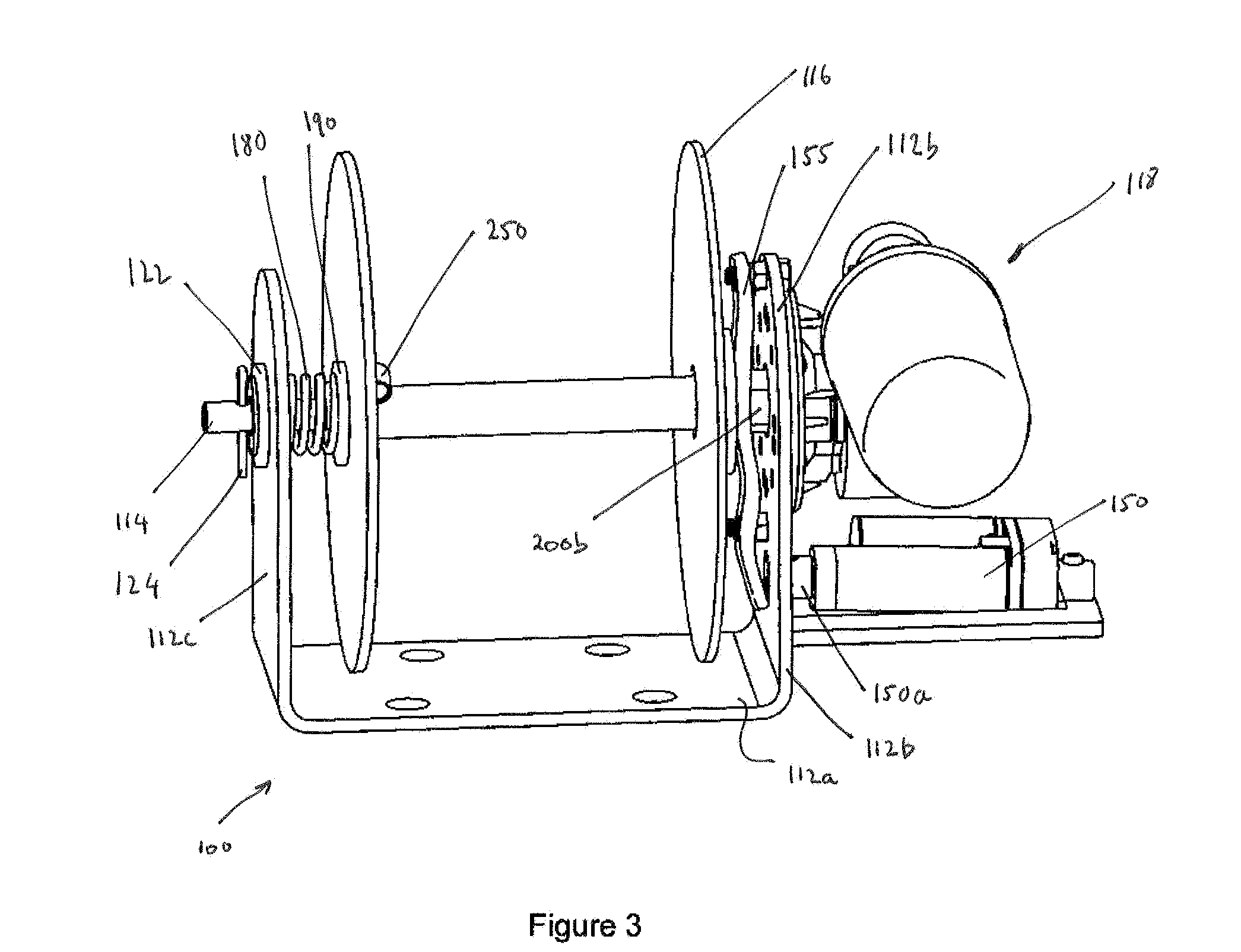

[0028]FIGS. 1 and 2 illustrate a prior art drum winch 10 for a marine vessel (not shown) that is used to lower and raise the vessel's anchor. The drum winch 10 includes a one piece mounting bracket (including a base plate 12a, an inner upright 12b and an outer upright 12c), a drive shaft 14, a drum 16 on which rode can be wound and a drive unit 18. Fasteners (not shown) extending through the base plate 12a of the mounting bracket 12 are used to securely mount the anchor drum winch 10 in the vessel's anchor well.

[0029]The drum 16 is in the form of a reel having a cylindrical hollow core. The drive shaft 14 extends through the core of the drum 16 and through a pair of bushes (not visible). The bushes mount the drum 16 on the drive shaft in such a manner as to ensure that the drum 16 only rotates with the drive shaft 14. Hence, when the drive shaft 14 is held stationary by the drive of the drive unit 18, the drum 16 is also prevented from rotating.

[0030]One end of the drive shaft 14 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com