Refrigeration apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

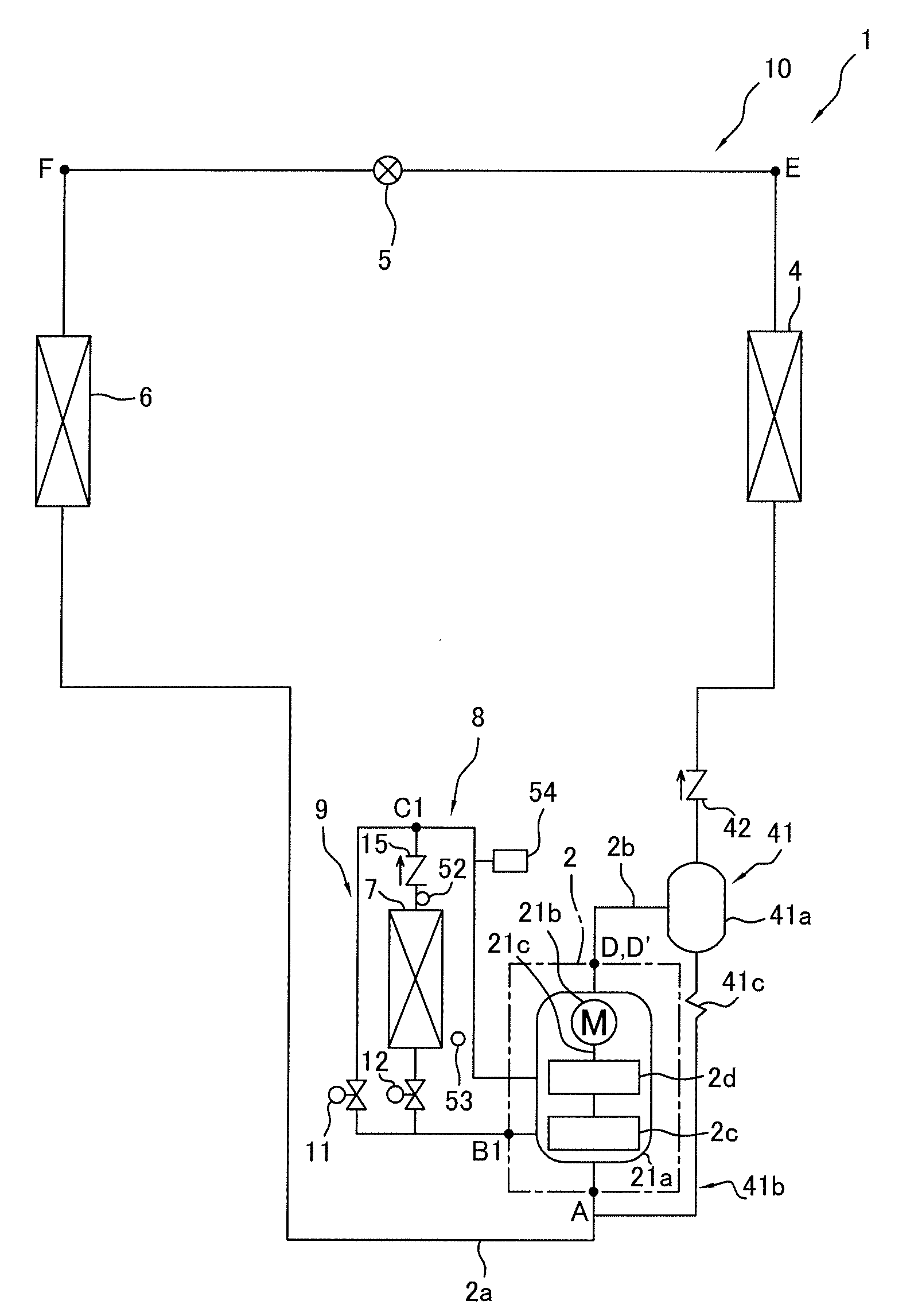

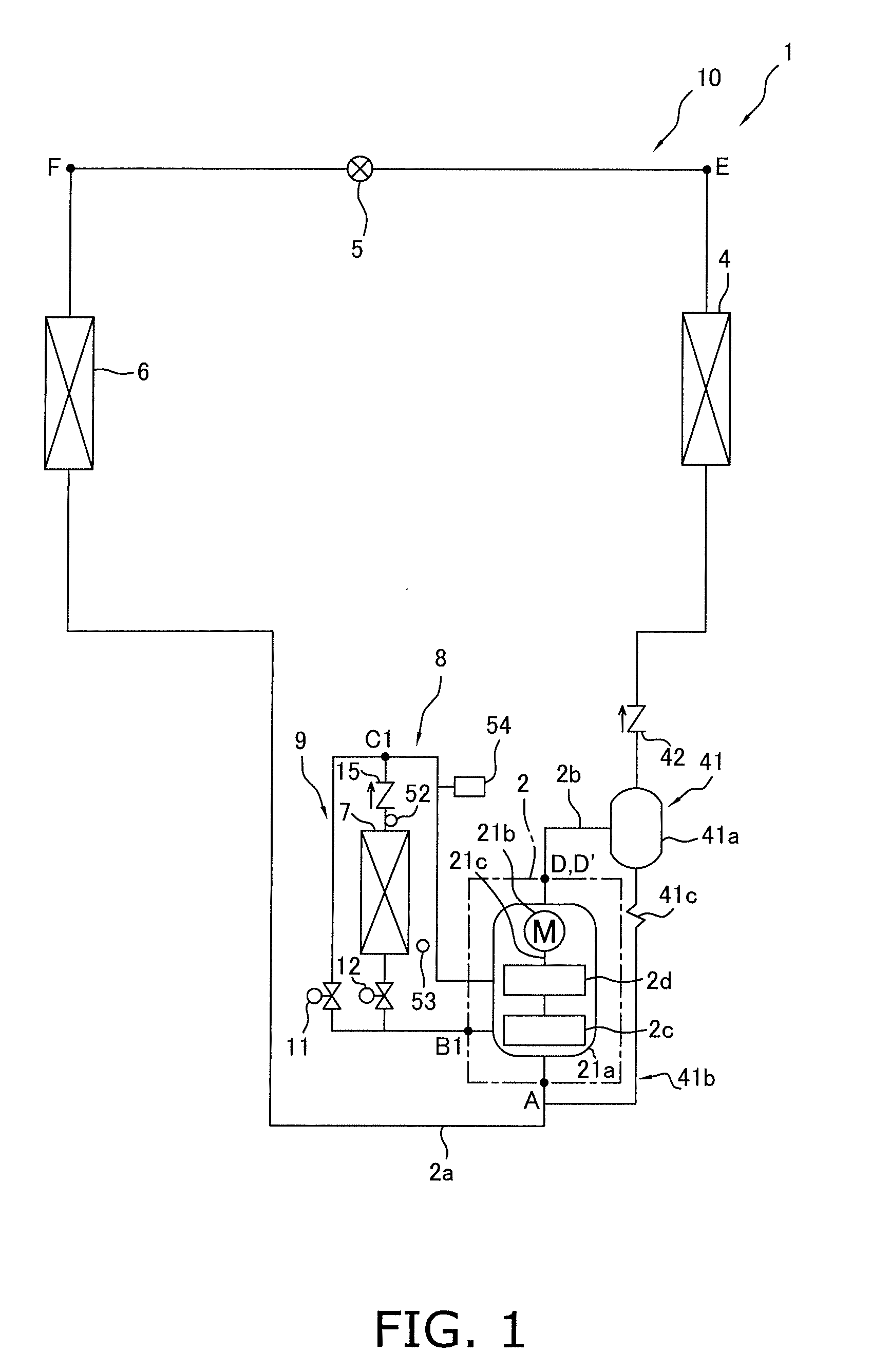

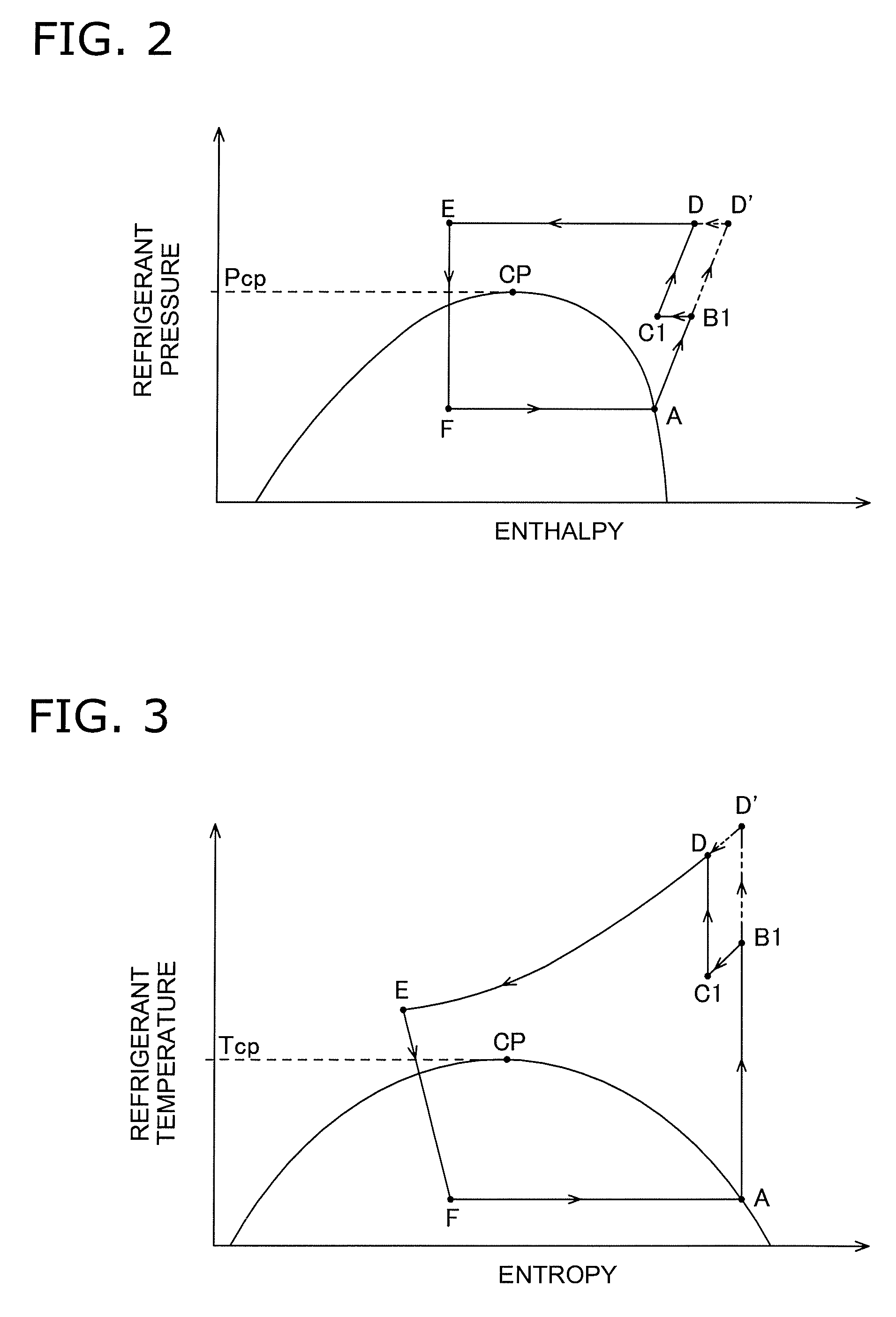

Method used

Image

Examples

modification 1

(3) Modification 1

[0071]In the embodiment described above, a heat exchanger is used as the intercooler 7 in which air is the heat source, but a heat exchanger may be used as the intercooler 7 in which water is used as the heat source.

[0072]For example, in a configuration that feeds water to the intercooler 7 via a water distribution tube 14 for intermediate cooling, as shown in FIG. 4, wet prevention control may be carried out so that a determination is made as to whether the temperature of the water (in this case, the temperature of the water fed to the intercooler 7 detected by a water temperature sensor 58 disposed in the water inlet side of the intercooler 7) as the heat source of the intercooler 7 is equal to or less than the saturation temperature of the intermediate-pressure refrigerant fed from the first-stage compression element 2c to the second-stage compression element 2d, or whether the temperature of the refrigerant (in this case, the temperature of the refrigerant dete...

modification 2

(4) Modification 2

[0076]Modification 1 described above is configured so that water is fed to the intercooler 7 via a water distribution tube 14 for intermediate cooling and so that a water on / off valve 14a is provided to the water distribution tube 14 for intermediate cooling; and in the case that it has determined that the temperature of the water as the heat source of the intercooler 7 or temperature of the refrigerant in the outlet of the intercooler 7 is equal to or less than the saturation temperature of the refrigerant fed from the first-stage compression element 2c to the second-stage compression element 2d, wet prevention control is carried out by allowing intermediate-pressure refrigerant not to flow to the intercooler 7 by using a intercooler bypass tube 9 and water fed to the intercooler 7 is stopped by closing the water on / off valve 14a (see FIG. 5). However, it is also possible to omit the intercooler bypass tube 9 including the intercooler bypass on / off valve 11, and / o...

modification 3

(5) Modification 3

[0078]In the configuration of Modification 2 described above (see FIG. 6), it is also possible to use a configuration in which the water on / off valve 14a is composed of a valve whose degree of opening can be adjusted, and when it has been determined that the temperature of the refrigerant in the outlet of the intercooler 7 is equal to or less than the saturation temperature of the refrigerant fed from the first-stage compression element 2c to the second-stage compression element 2d, wet prevention control is carried out so as to reduce the flow rate of water fed to the intercooler 7 by reducing the degree of opening of the water on / off valve 14a to prevent the refrigerant drawn into the second-stage compression element 2d from becoming wet, and furthermore so as to control the flow rate of the water that flows through the intercooler 7 so that the temperature of the refrigerant in the outlet of the intercooler 7 become greater than the saturation temperature of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com