Eddy current for the characterization of broached tube support plate blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

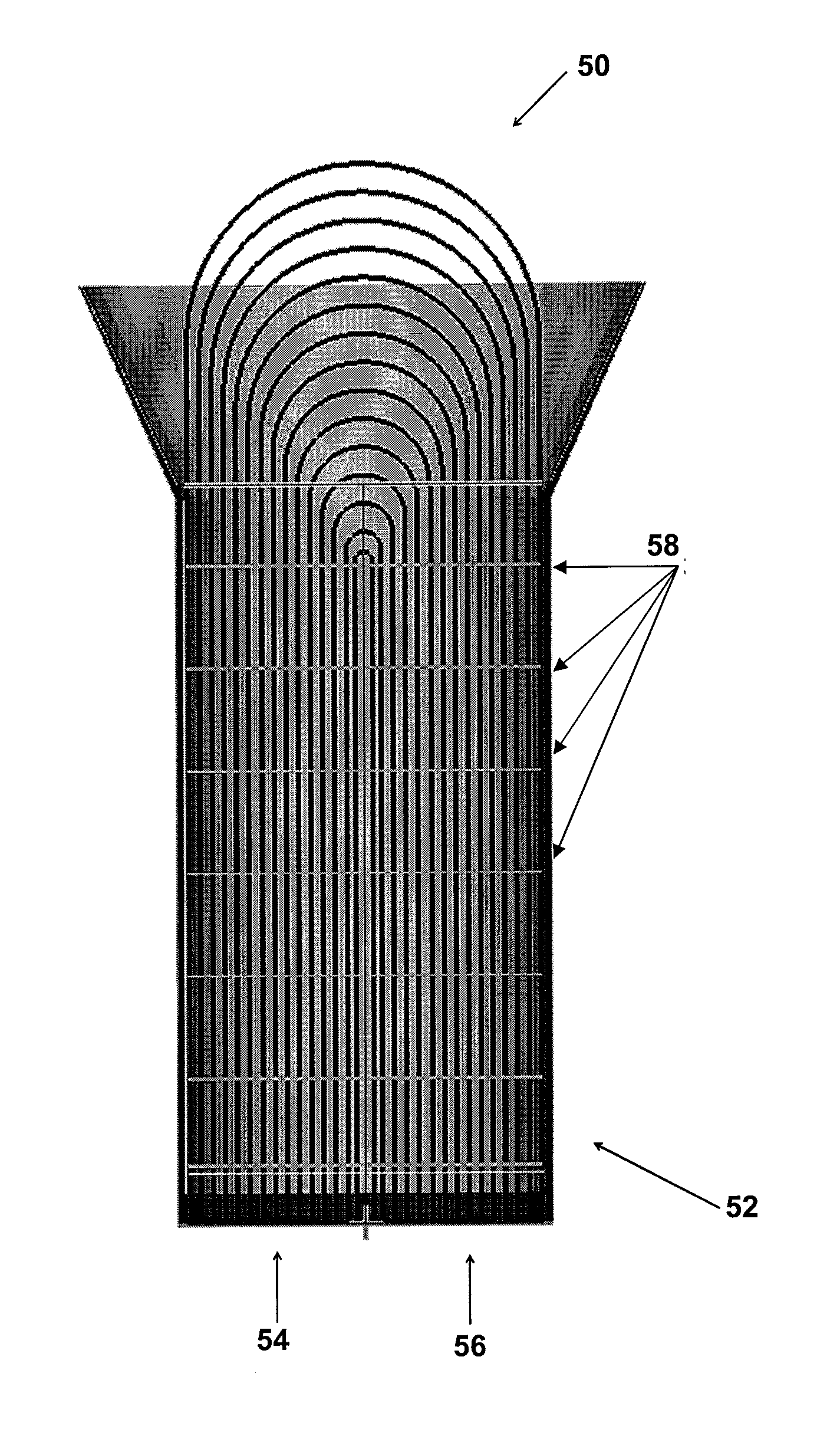

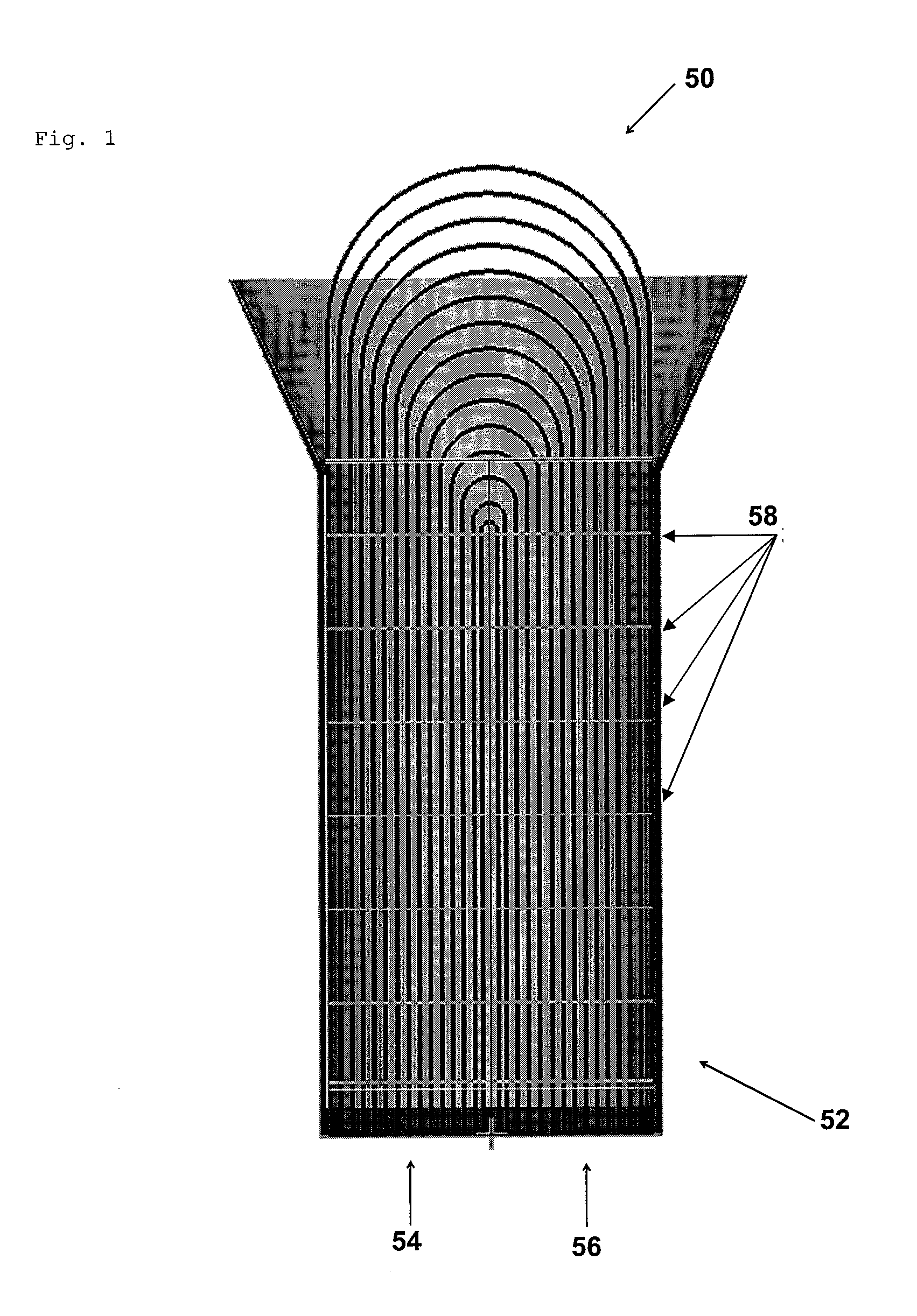

[0019]Bobbin coil eddy current data is used to make calibrated quantitative measurements of deposition around and within the support. A bobbin coil eddy current probe is used to sense changes in the quantity of material deposited in and around the support plate as the probe is drawn axially through the tube. Various alterations in the eddy current TSP signal response are detected during the analysis of the eddy current data for open tube surface deposition and tubing flaws. Five separate measurements to characterize the deposition in the TSP region may be performed. Although these measured values may be used to determine the deposit loading within each tube support intersection, a more appropriate use has been found to determine the flow restriction present at each tube support intersection and subsequently the collective effect of the flow restriction of the population of tube intersections on several operational concerns for the steam generator.

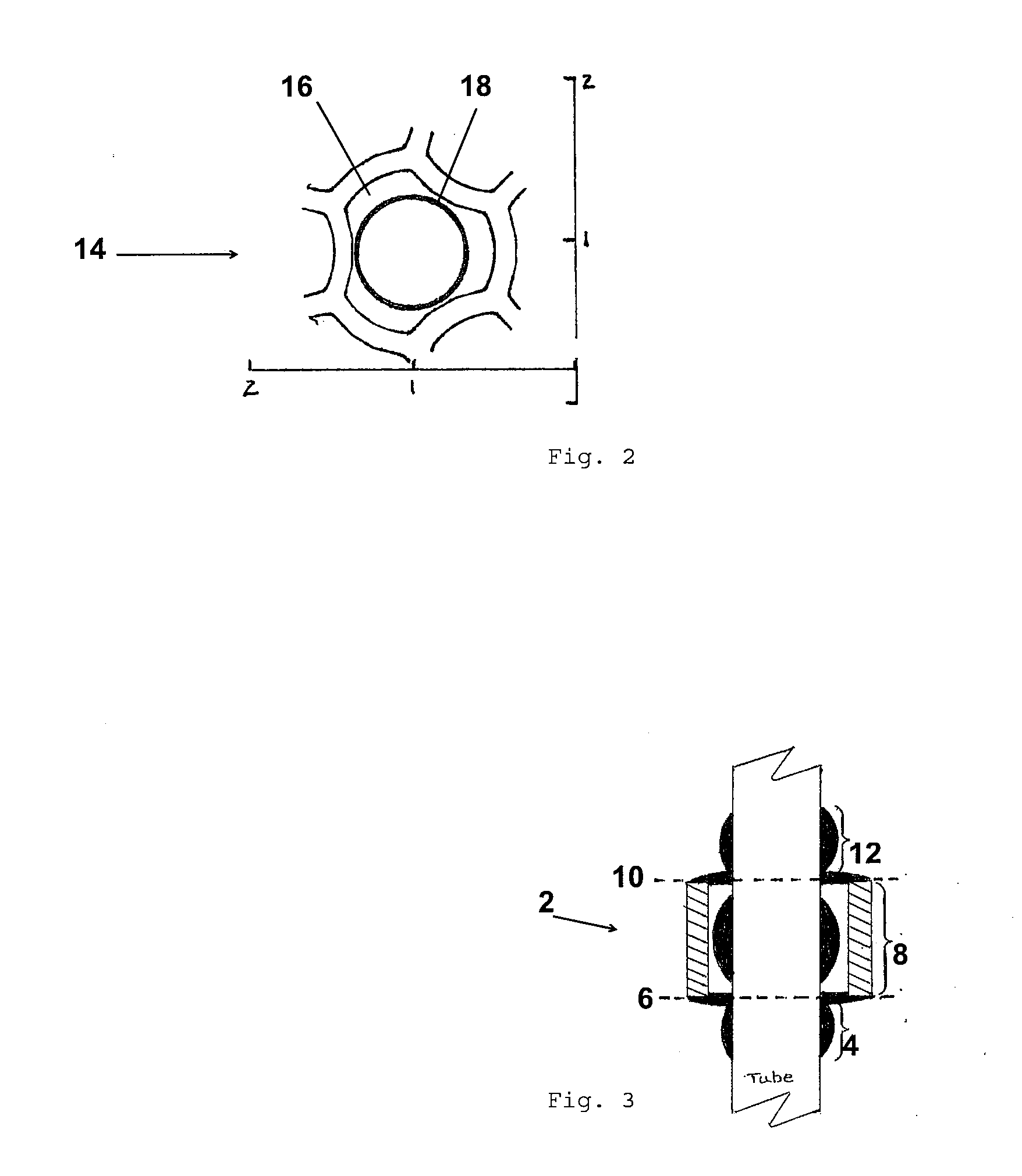

[0020]FIG. 3 shows a section of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com