Container for Bottle-In-Box Package

a bottle-in-box and container technology, applied in the field of plastic bottles, can solve the problems of unsuitable consumer use, leakage of seams where sheets are joined, and the collapse of thermoplastic laminate bags, so as to reduce cost and environmental impact, and maintain structural stability. the effect of preferabl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

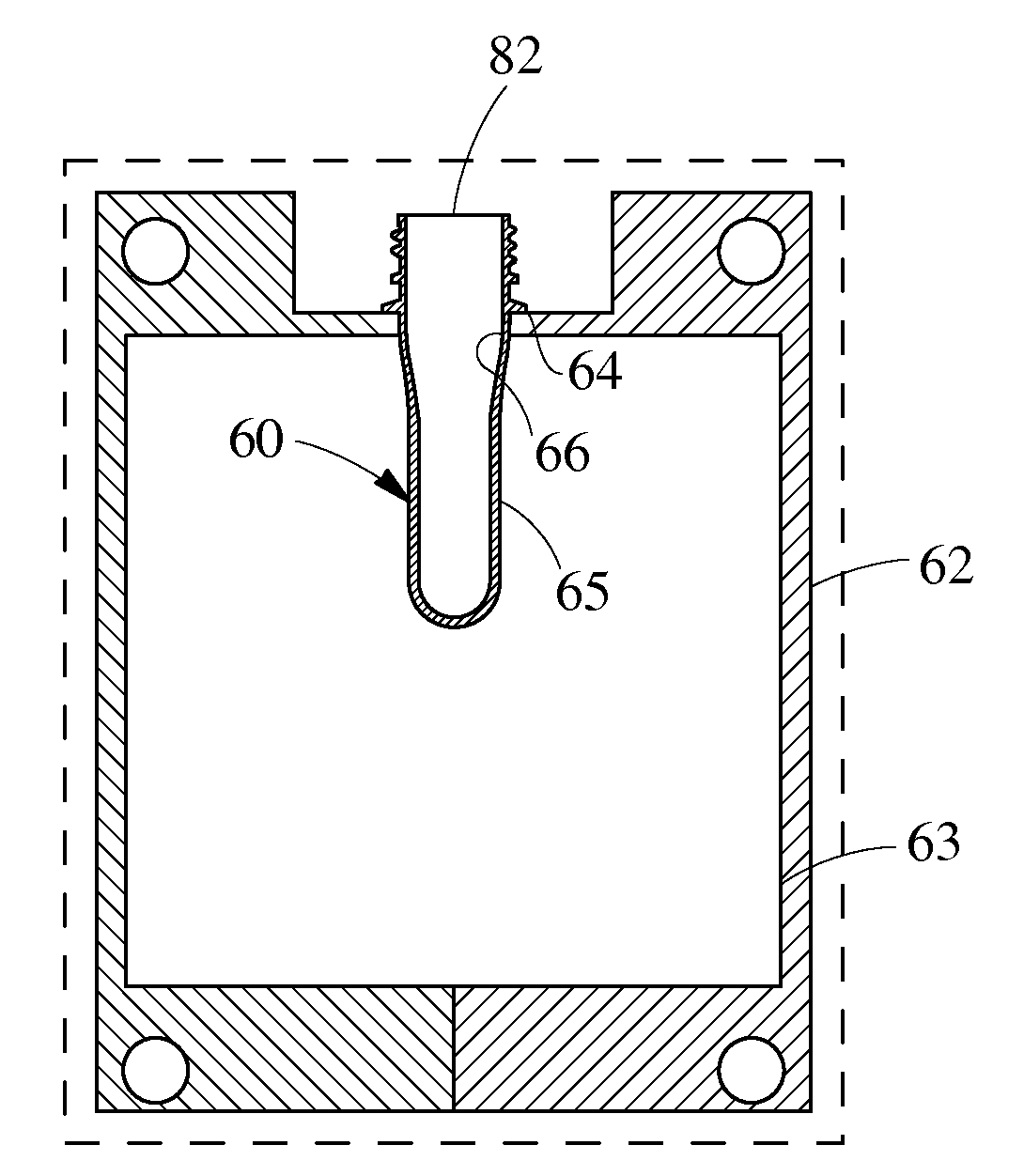

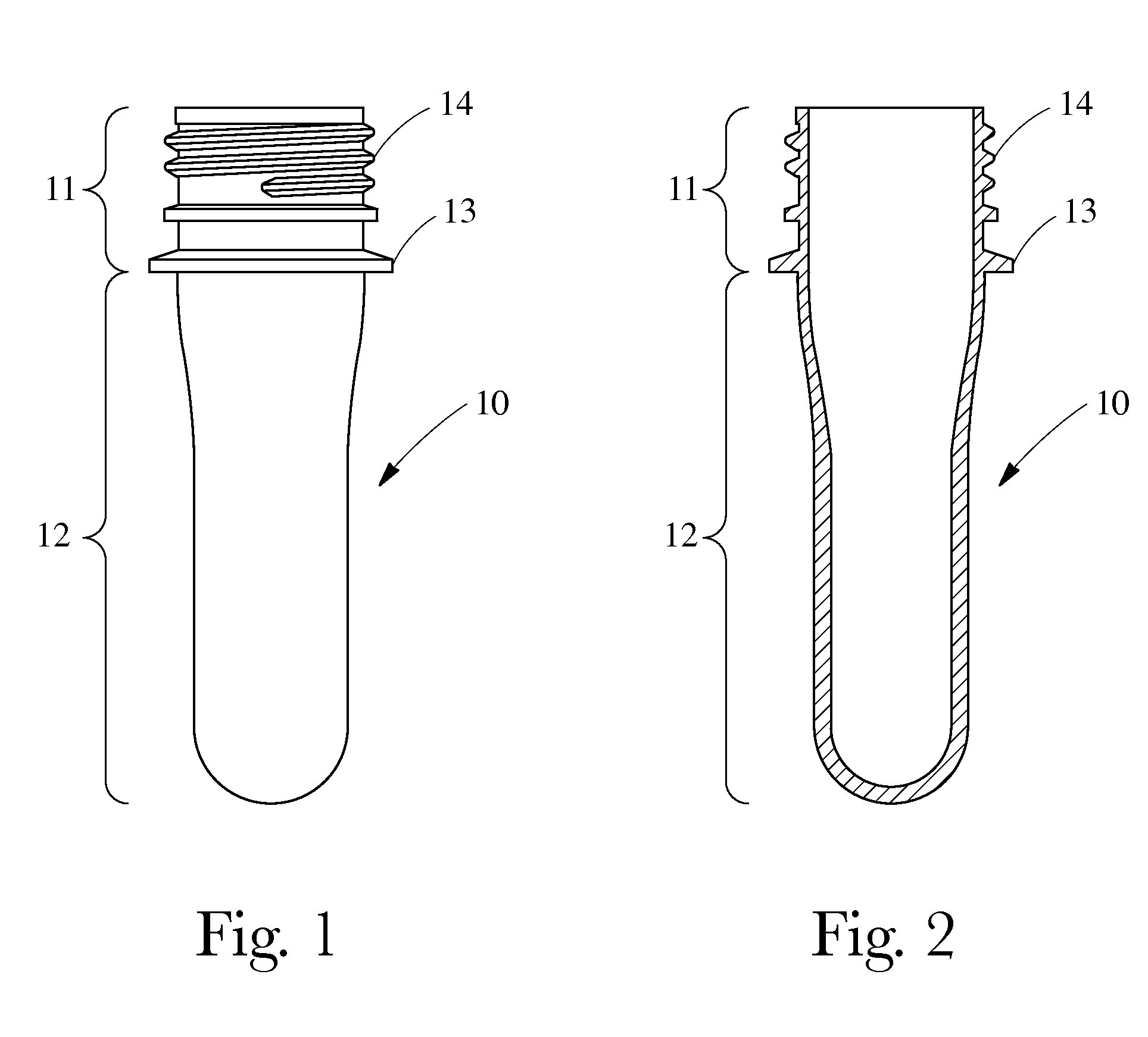

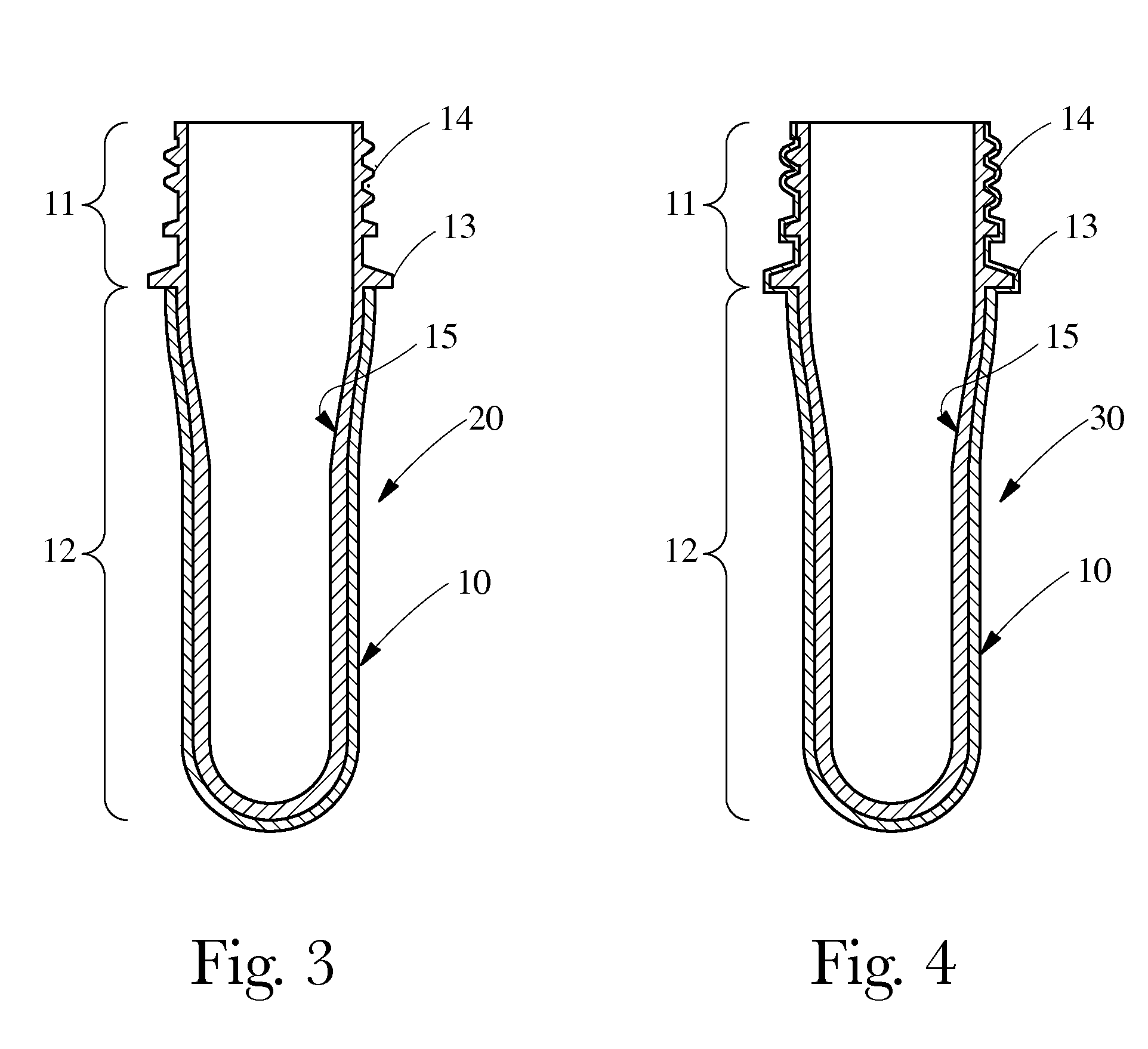

[0029]A suitable container useful for the storage, shipment, and / or dispensing of flowable compositions may be formed from polypropylene. Containers herein include a blow molded portion and a non-blow molded portion integrally connected.

Container

[0030]Containers according to the present invention include a blow molded portion and a non-blow molded portion integrally connected. In one embodiment, the container has a height to width ratio of from about 3:1 to about 1:3, alternatively from about 2:1 to about 1:2 and still alternatively from about 1:1 with length measured at the longest dimension and disregarding the dispenser when measuring.

[0031]In one embodiment, the container contains within a composition. When the container contains within a composition, the container / composition combination may be non-pressurized. As used herein, “non-pressurized” means that that the containers are not subjected to gas or other pressurization means that would result in the increase of pressure ins...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural modulus | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com