Turbine housing with wall cladding

a technology of wall cladding and turbine housing, which is applied in the direction of machines/engines, stators, liquid fuel engines, etc., can solve the problems of leakage in the joint area and leakage herewith, and achieve the effect of simple sealing of the joints, improved performance and improved sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019]The figures illustrate very simplified representations in each instance, in which only the essential components needed to describe the invention are shown. Identical and / or functionally identical components are provided with the same reference characters throughout all the figures.

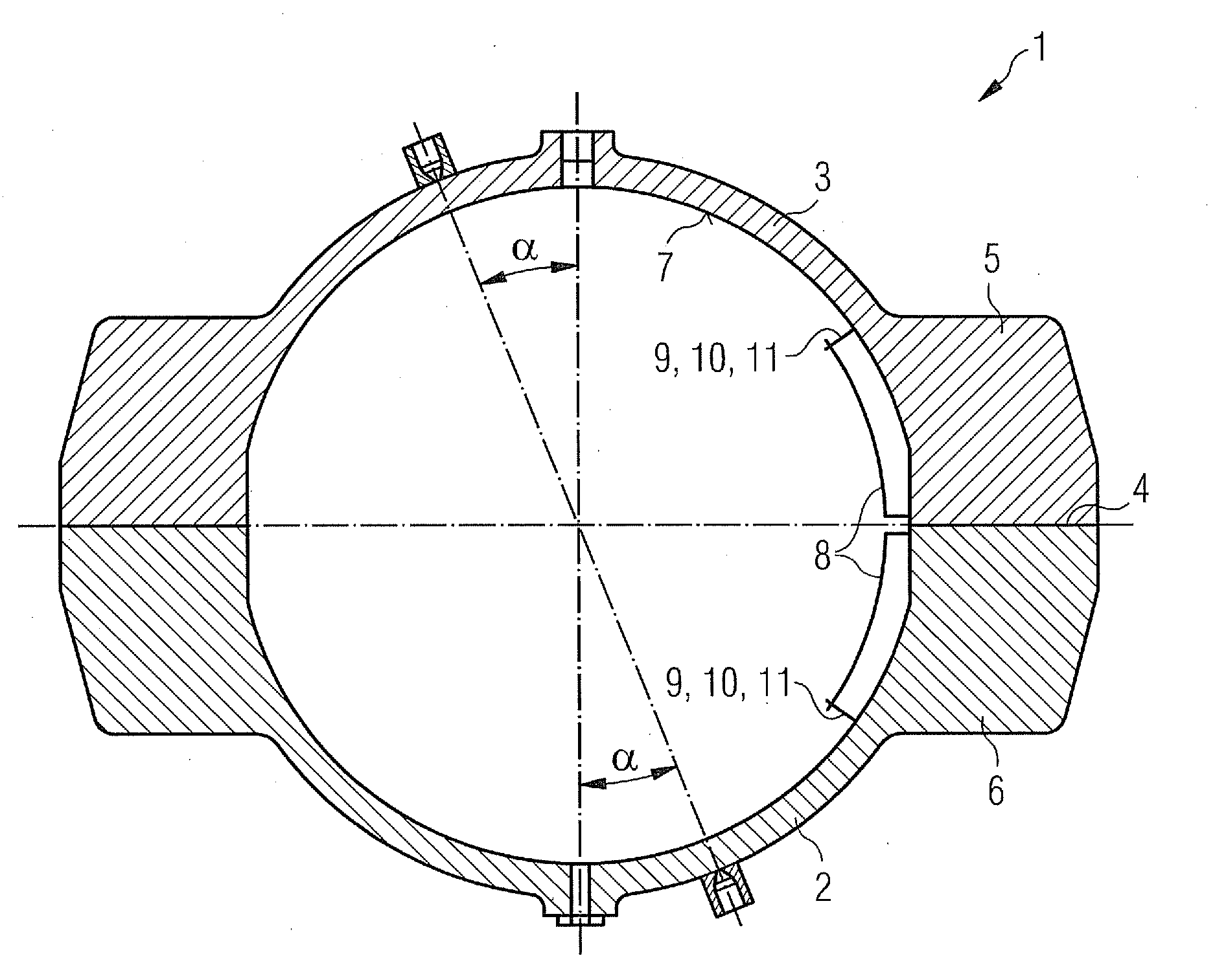

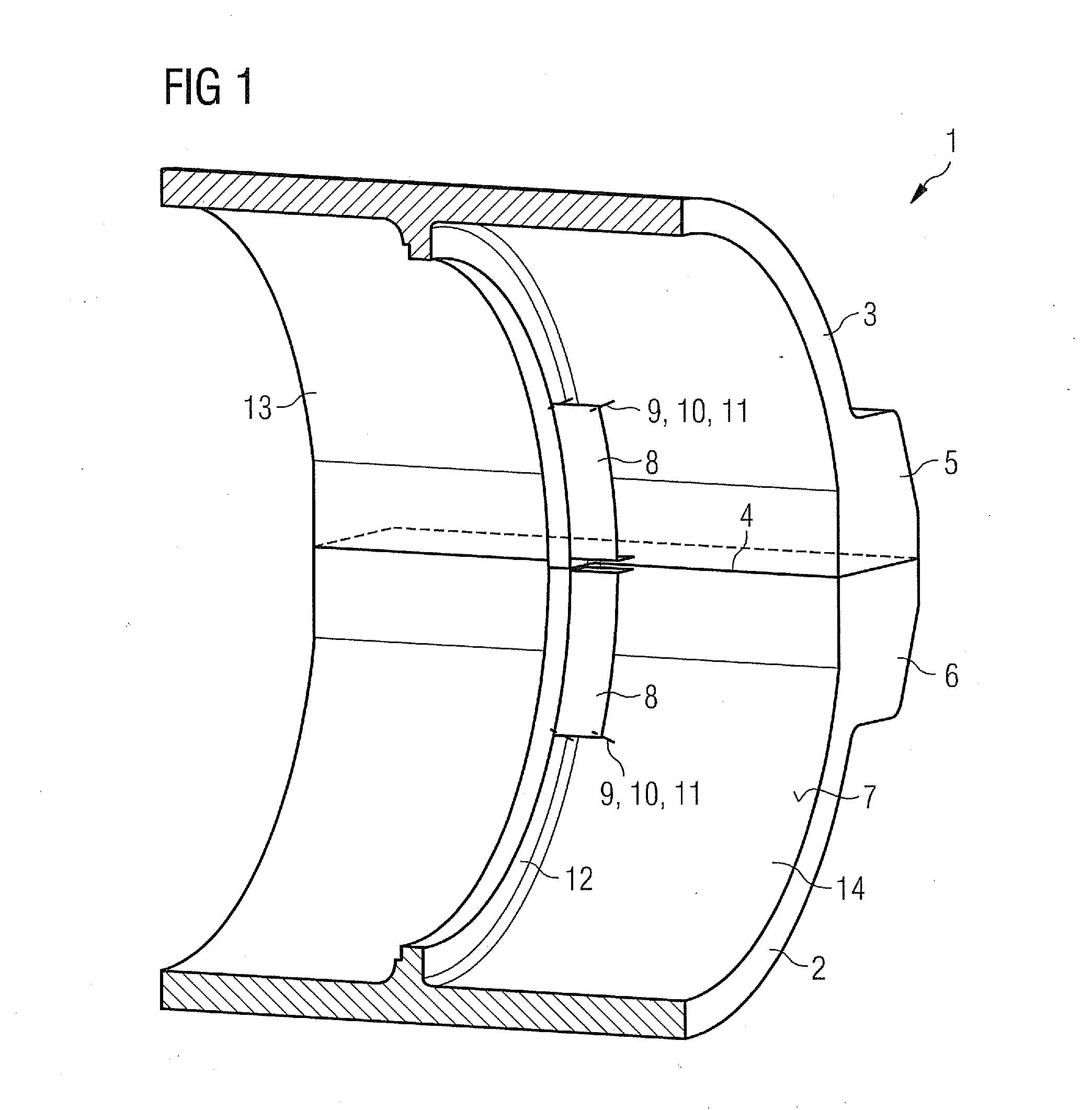

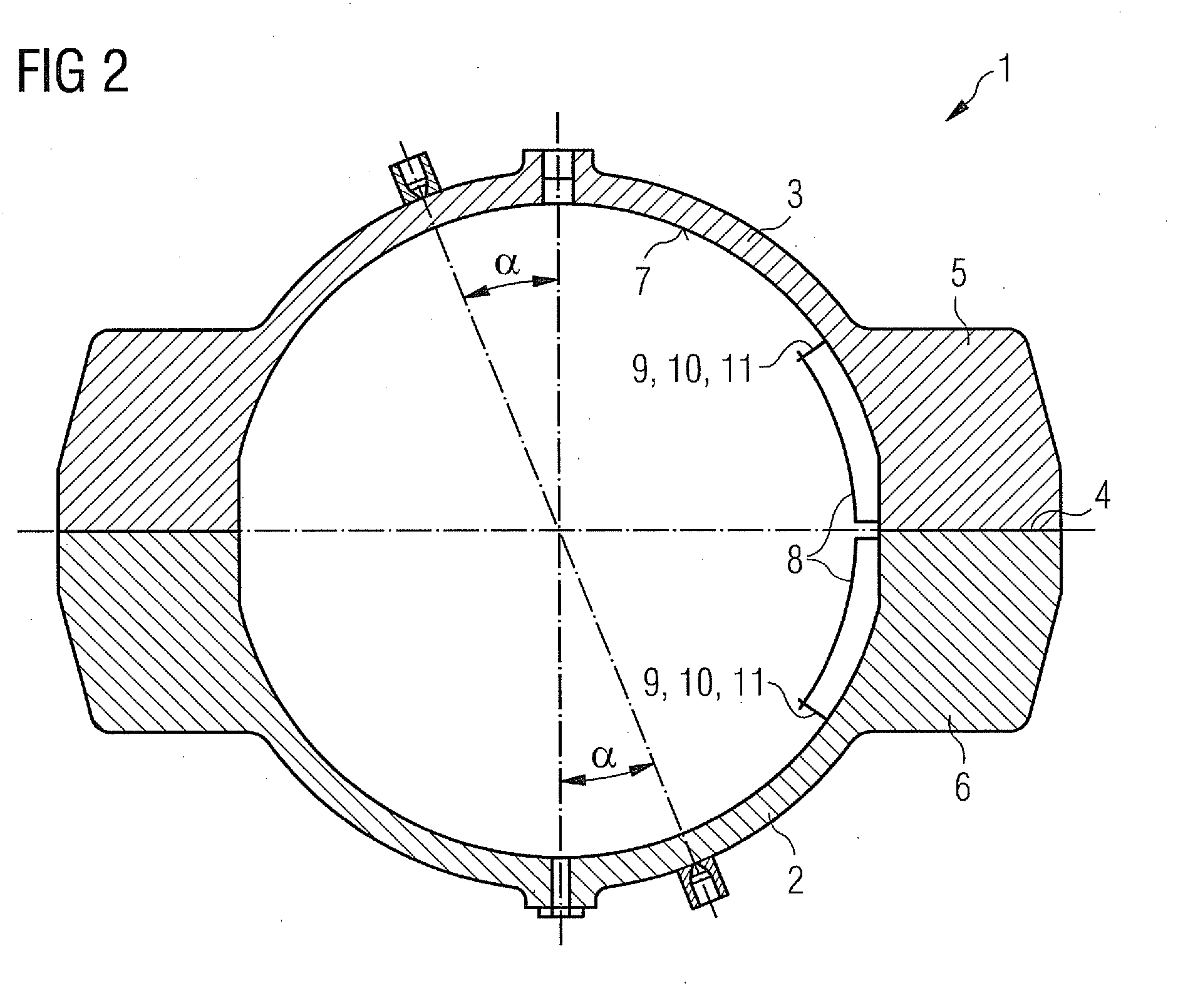

[0020]FIG. 1 shows a three-dimensional section through an inventive turbine housing. The turbine housing 1 includes a turbine housing lower part 2 and a turbine housing upper part 3. The two turbine housing parts 2, 3 are joined to one another in the assembled state. Joints 4 thereby form on the joining areas in each instance. To ensure that no fluid can escape outwards from the interior of the turbine housing 1, the joints 4 must be closed in as tight a fashion as possible. To this end, the turbine housing lower part 2 and the turbine housing upper part 3 are fixedly screwed to one another. To enable a good screwing connection between the two turbine housings 2 and 3, both turbine housing parts comp...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap